Lifting support

A technology for raising and lowering brackets and tabletops, which is applied in the direction of lifting devices, etc., can solve the problems of affecting construction, not being convenient to move, and burying workers, so as to achieve the effects of improving production efficiency, meeting safety needs, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the examples.

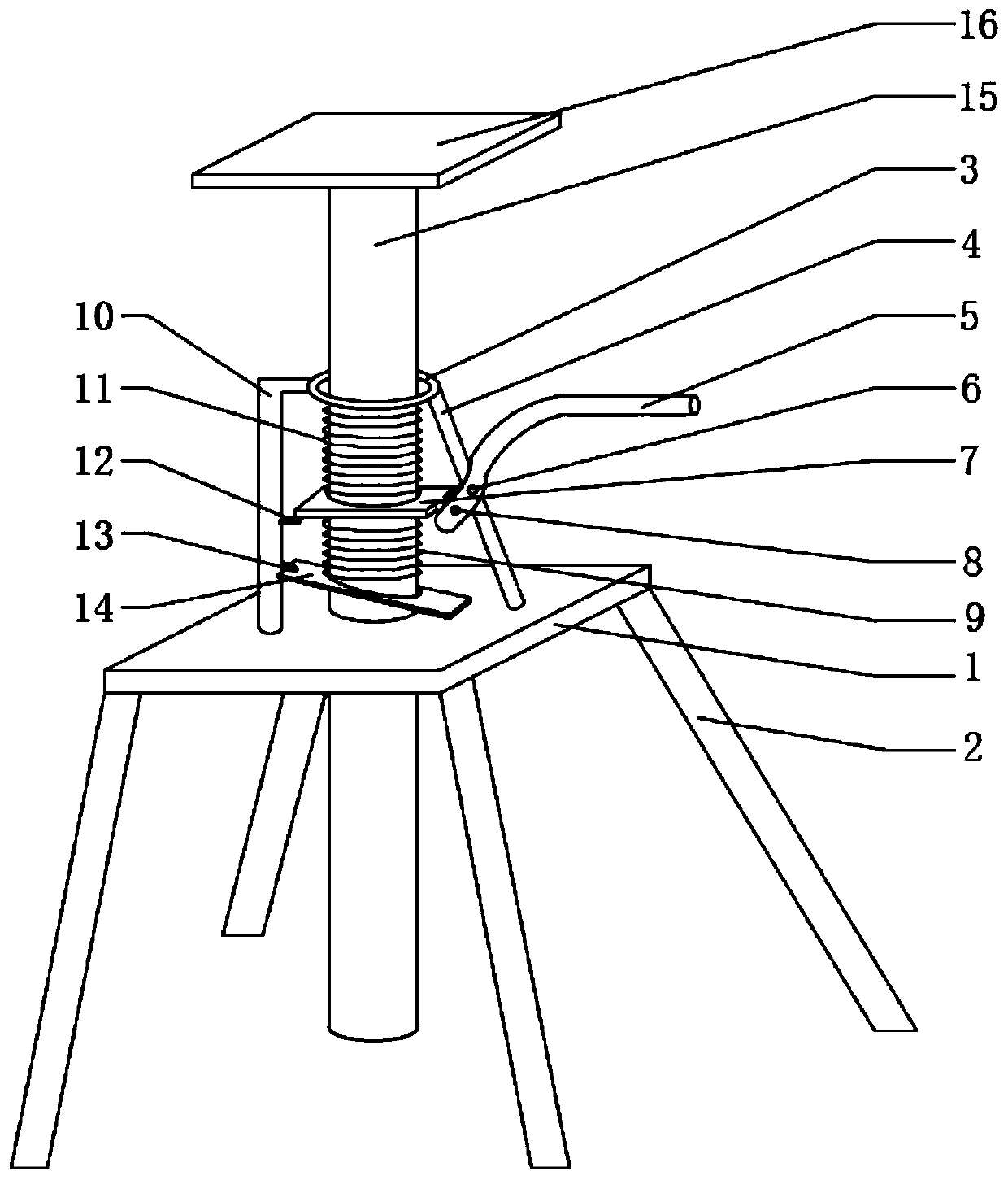

[0014] Such as figure 1 The shown lifting bracket includes a leg 2 and a table 1 fixedly connected to the upper end of the leg 2. A through hole is opened in the middle of the table 1, and a top plate 16 is pierced in the through hole. A top post 15, the top post 15 is sequentially set with a fixed ring 3 connected to a diagonal bar 4 on one side, an upper spring 11, a toggle plate 7, a lower spring 9, and a circular center hole provided on the top post 15. Clamping plate 14, the diameter of the central hole of the clamping plate 14 is greater than the diameter of the cross-section of the top column 15, in another embodiment of the present invention, the shape of the central hole of the clamping plate 14 is oval, The long axis of the central hole of the clamping plate 14 is greater than the diameter of the cross section of the top column 15; the other side of the fixing ring 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com