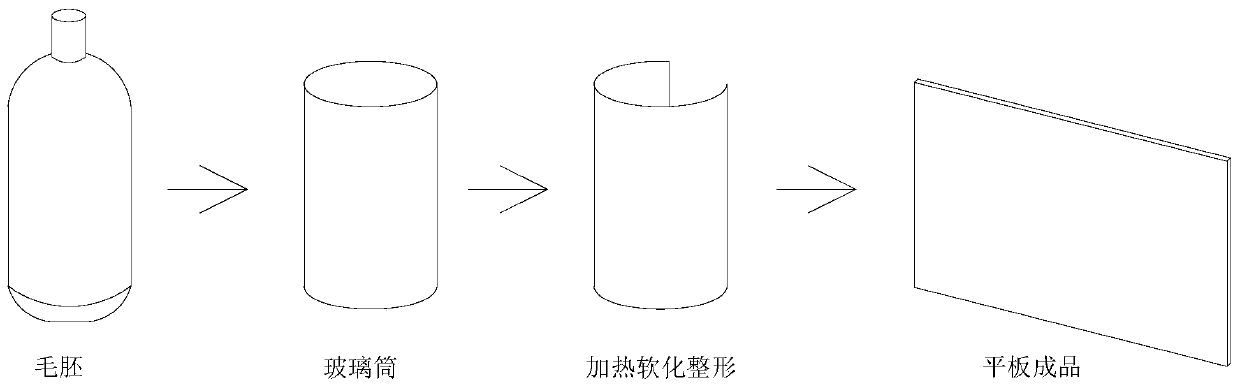

Preparation method of colored flat art glass

A technology of artistic glass and color registration, which is applied in glass manufacturing equipment, blowing of glass cylinders for plate making, and glass molding, etc. It can solve problems such as impossibility, cracking or falling off, and limited service life, and achieve improvement Efficiency and processing performance, the effect of enhancing the effect of artistic expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the present invention will be briefly introduced below in conjunction with the drawings and the description of the embodiments or the prior art. Obviously, the following description about the structure of the drawings is only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

[0029] The technical solutions provided by the present invention will be described in detail below through embodiments with reference to the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention.

[0030] In some instances, some implementations are not described or described in detail because they pertain to prior or conventional art.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com