Aluminum alloy material with high strength and high thermal conductivity, preparation method thereof, and heat sink

An aluminum alloy material, high thermal conductivity technology, applied in the field of aluminum alloy, can solve the problems of inapplicable production of radiators, small cross-sectional area of radiators, complicated production process, etc., to eliminate unbalanced solidification eutectic structure, improve thermal conductivity, The effect of strengthening the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

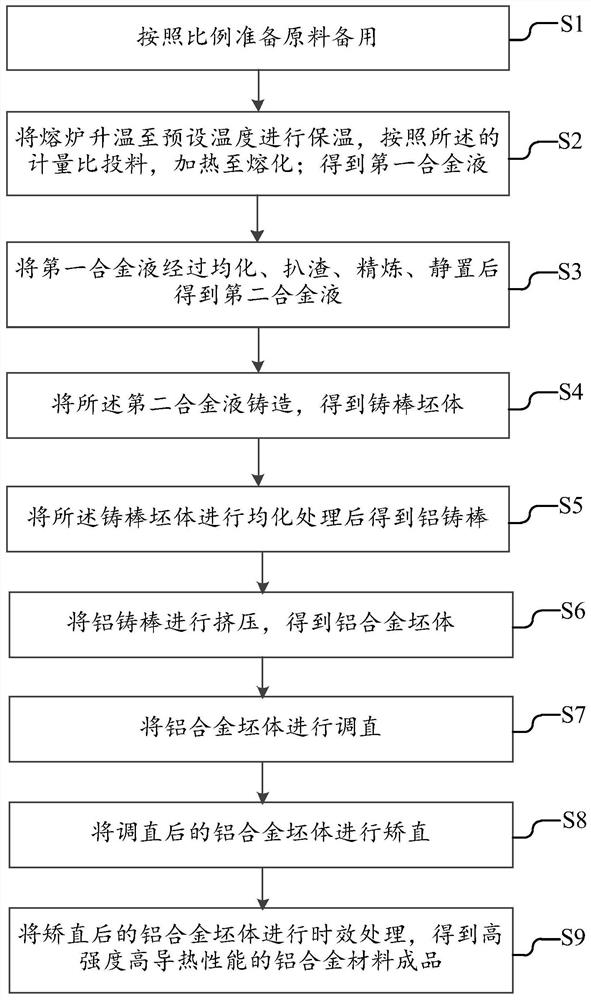

[0043] For this reason, the invention provides a kind of preparation method of the aluminum alloy material of high strength and high thermal conductivity, see figure 1 , which includes the following steps:

[0044] S1: Prepare raw materials according to the proportion for use;

[0045] Wherein, the raw material formula in weight percentage is as follows:

[0046] Si 2.5~5%, Mg 0.8~1.8%, Sr 0.01~0.1%, Fe 0.05~0.5%, Ti 0.01~0.5%, Cu 0.01~0.1%, Mn 0.01~0.05%, the balance is aluminum;

[0047] Specifically, the mechanical properties of the aluminum alloy in the present invention are mainly through the Mg 2 Si phase and excess Si content guarantee, the present invention controls Si content to be 2.5~5%, and Mg content is 0.8~1.8%; The present invention has promoted Si surplus, has promoted the yield strength and the tensile strength of aluminum alloy; Simultaneously due to this The content of other elements such as Fe, Cu, Mn, Zn is low in the invention, in the manufacturing pro...

Embodiment 1

[0095] This embodiment provides an aluminum alloy material with high strength and high thermal conductivity, the preparation method of which is as follows:

[0096] (1) Raw materials are prepared according to the proportion for use; among them, the formula of raw materials in weight percentage is as follows:

[0097] Si 2.5%, Mg 0.8%, Sr 0.01%, Fe 0.05%, Ti 0.01%, Cu 0.01%, Mn 0.01%, and the balance is aluminum;

[0098] (2) Heating the furnace to 720°C for heat preservation, feeding materials according to the raw material formula, and heating until melting; obtaining the first alloy liquid;

[0099] (3) Homogenizing the first alloy liquid, removing slag, refining, and standing still to obtain the second alloy liquid; wherein, the refining temperature is 720°C and the time is 20 minutes;

[0100] (4) Casting the second molten alloy to obtain a cast billet;

[0101] (5) Homogenizing the cast billet body to obtain an aluminum cast rod; wherein, the homogenizing treatment tempe...

Embodiment 2

[0107] This embodiment provides an aluminum alloy material with high strength and high thermal conductivity, the preparation method of which is as follows:

[0108](1) Raw materials are prepared according to the proportion for use; among them, the formula of raw materials in weight percentage is as follows:

[0109] Si 5%, Mg 1.8%, Sr 0.1%, Fe 0.5%, Ti 0.5%, Cu 0.1%, Mn 0.05%, and the balance is aluminum;

[0110] (2) Heating the furnace to 750°C for heat preservation, feeding materials according to the raw material formula, and heating until melting; obtaining the first alloy liquid;

[0111] (3) Homogenizing the first alloy liquid, removing slag, refining, and standing still to obtain the second alloy liquid; wherein, the refining temperature is 750°C and the time is 30 minutes;

[0112] (4) Casting the second molten alloy to obtain a cast billet;

[0113] (5) Homogenizing the cast billet body to obtain cast aluminum rods; wherein, the homogenizing treatment temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com