Rare earth-containing high-strength and tough roll steel, its preparation method and heat treatment process

A high-strength, rolling technology, which is applied in the fields of rare earth-containing high-strength and tough roll steel and its preparation and heat treatment process, can solve the problems of poor toughness, unknown hardness and toughness and other properties, and achieve long life, less alloying elements and high hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The chemical composition (percentage by weight) of the slab of a rare earth-containing high-strength and tough roll steel is: C 0.68%, Si0.45%, Mn 1.24%, P0.015%, S0.002%, Cr 1.32%, Mo 0.69% , RE 0.30%, the balance is Fe and unavoidable impurities.

[0025] In the billet preparation process: the smelting process uses a 1-ton intermediate frequency furnace for smelting. When the temperature of the molten steel reaches 1580°C, aluminum is inserted for deoxidation and the steel is tapped, and then casting is carried out. The ladle is still for 15 minutes, then the molten steel is poured into the tundish, poured into the dried sand mold after mechanical stirring, and the cast slab is taken out after cooling.

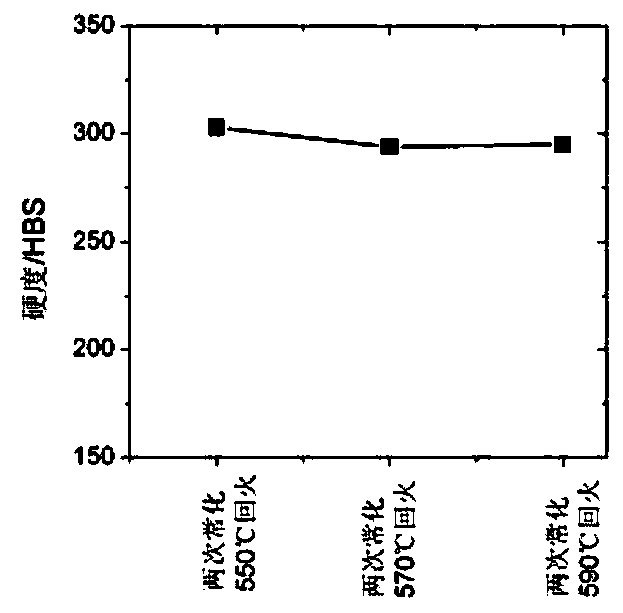

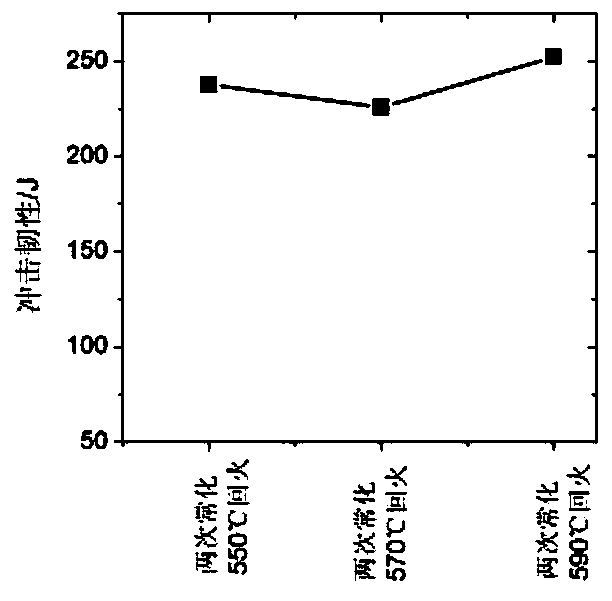

[0026] The heat treatment process for the slab is as follows: the heat-treated roll steel samples corresponding to the heating temperature of 830°C are subjected to high-temperature annealing treatment at 700°C and then normalized twice, and the tempering temperatures...

Embodiment 2

[0028] The chemical composition (percentage by weight) of the slab of a rare earth-containing high-strength and tough roll steel is: C 0.68%, Si0.45%, Mn 1.24%, P0.015%, S0.002%, Cr 1.32%, Mo 0.69% , RE 0.30%, the balance is Fe and unavoidable impurities.

[0029] In the billet preparation process: the smelting process uses a 1-ton intermediate frequency furnace for smelting. When the temperature of the molten steel reaches 1580°C, aluminum is inserted for deoxidation and the steel is tapped, and then casting is carried out. The ladle is still for 15 minutes, then the molten steel is poured into the tundish, poured into the dried sand mold after mechanical stirring, and the cast slab is taken out after cooling.

[0030] The heat treatment process for the slab is as follows: the heat-treated roll steel samples corresponding to the heating temperature of 890°C are subjected to high-temperature annealing treatment at 700°C and then normalized twice, and the tempering temperatures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com