A Reverse Circulation Drilling Circulation Channel Switching Nipple

A circulation channel and reverse circulation technology, applied to drilling equipment, drill pipes, drill pipes, etc., can solve the problems of high cost and production difficulty, achieve the effects of reducing drilling friction, strengthening sealing performance, and ensuring drilling safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

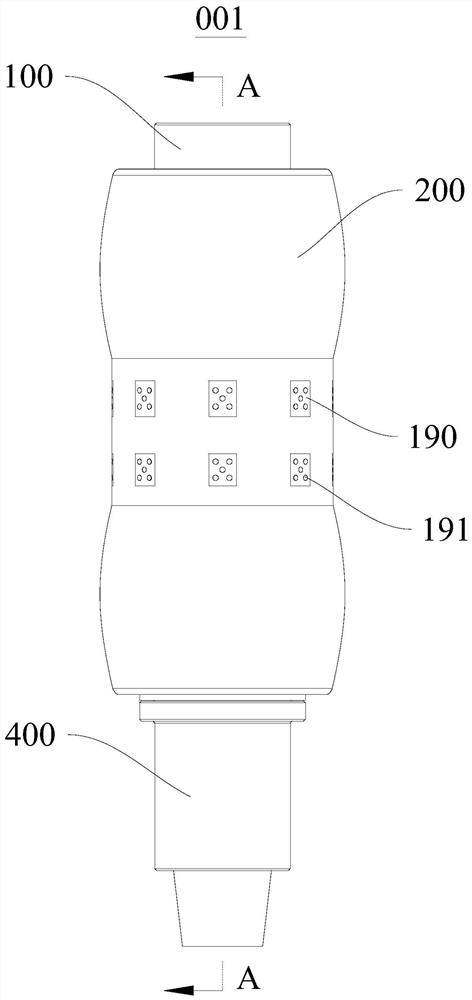

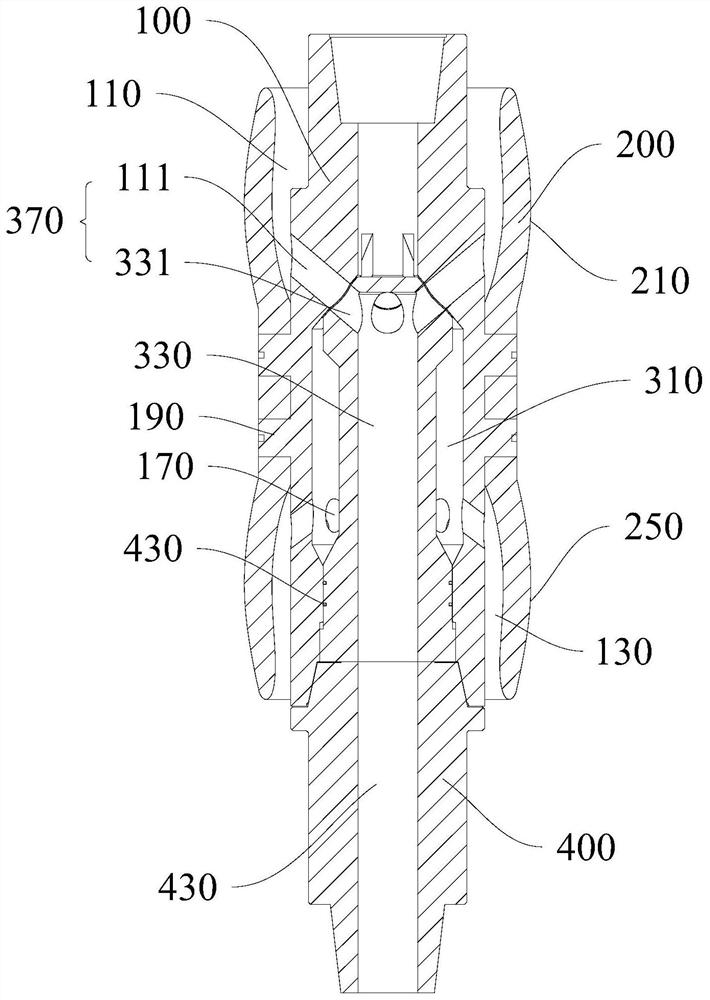

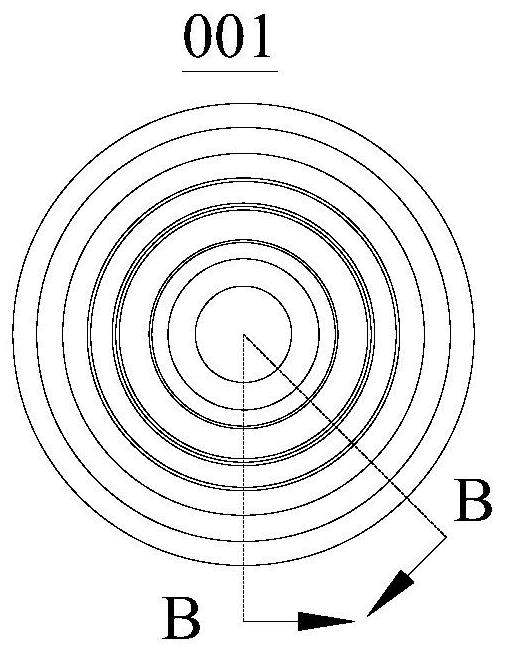

[0041] This embodiment provides a reverse circulation drilling circulation channel switching nipple 001, please refer to figure 1 , figure 2 , image 3 and Figure 4 , this reverse circulation drilling circulation channel switching nipple 001 includes an upper joint 100 , a rubber plug 200 , a reversing mandrel 300 and a lower joint 400 .

[0042] see Figure 11 and Figure 12 , this reverse circulation drilling circulation channel switching nipple 001 is installed in the casing 600 . Specifically, the casing 600 is provided with a working hole 610, and the drilling pipe 700 and the reverse circulation drilling circulation channel switching nipple 001 are installed in the working hole 610. An annular flow path is formed between the casing 600 and the drilling pipe 700, and due to the rubber plug 200 is arranged in close contact with the inner wall of the working hole 610, that is, the maximum outer diameter of the rubber plug 200 is larger than the inner diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com