Rotary chuck for remedial work

A rotary chuck and operation technology, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems that the anti-top chuck and anti-fall chuck cannot rotate with the oil pipe, and cannot meet the requirements of rotation operations, so as to achieve convenient The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

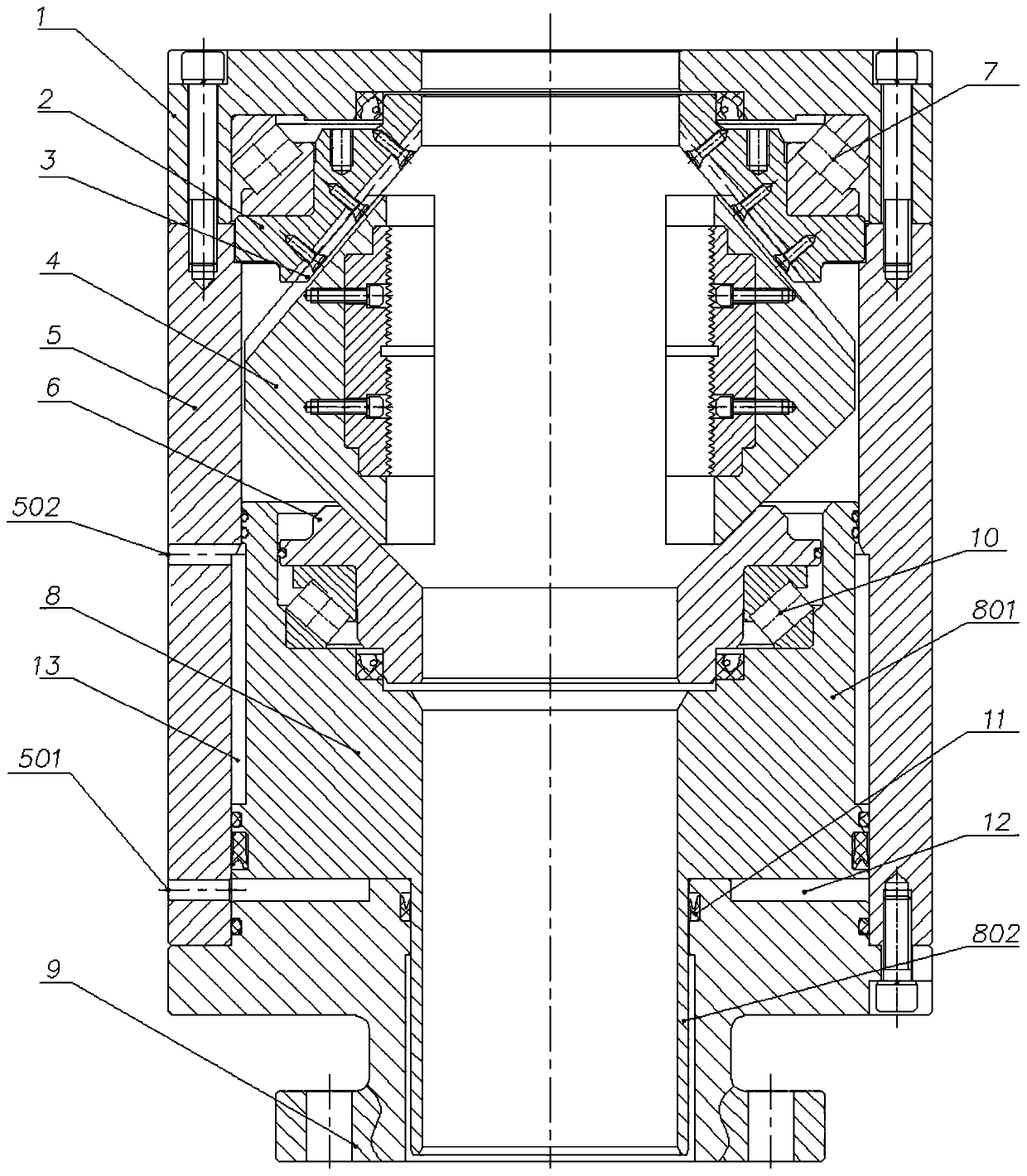

[0030] refer to figure 1 , including an intermediate casing formed by connecting an upper flange 1, an intermediate casing 5 and a lower flange 9 in series.

[0031] The casing is provided with an upper rotating body 2 , two dovetail-shaped guide keys 3 , a slip body assembly 4 , a lower rotating body 6 and a piston 8 in sequence from top to bottom. The inner holes of the lower end of the upper rotating body 2 and the upper end of the lower rotating body 6 are tapered holes; both ends of the slip body assembly 4 are tapered surfaces.

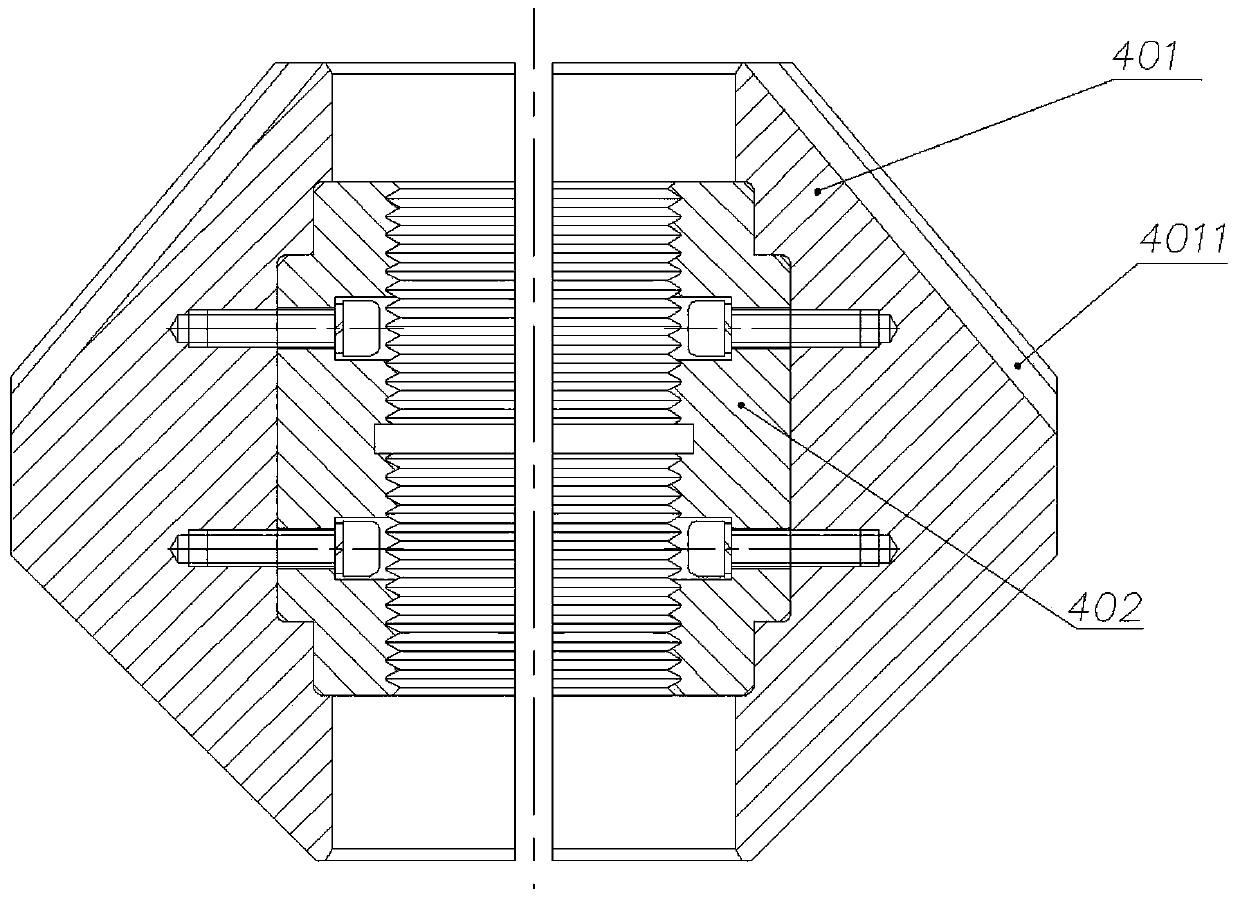

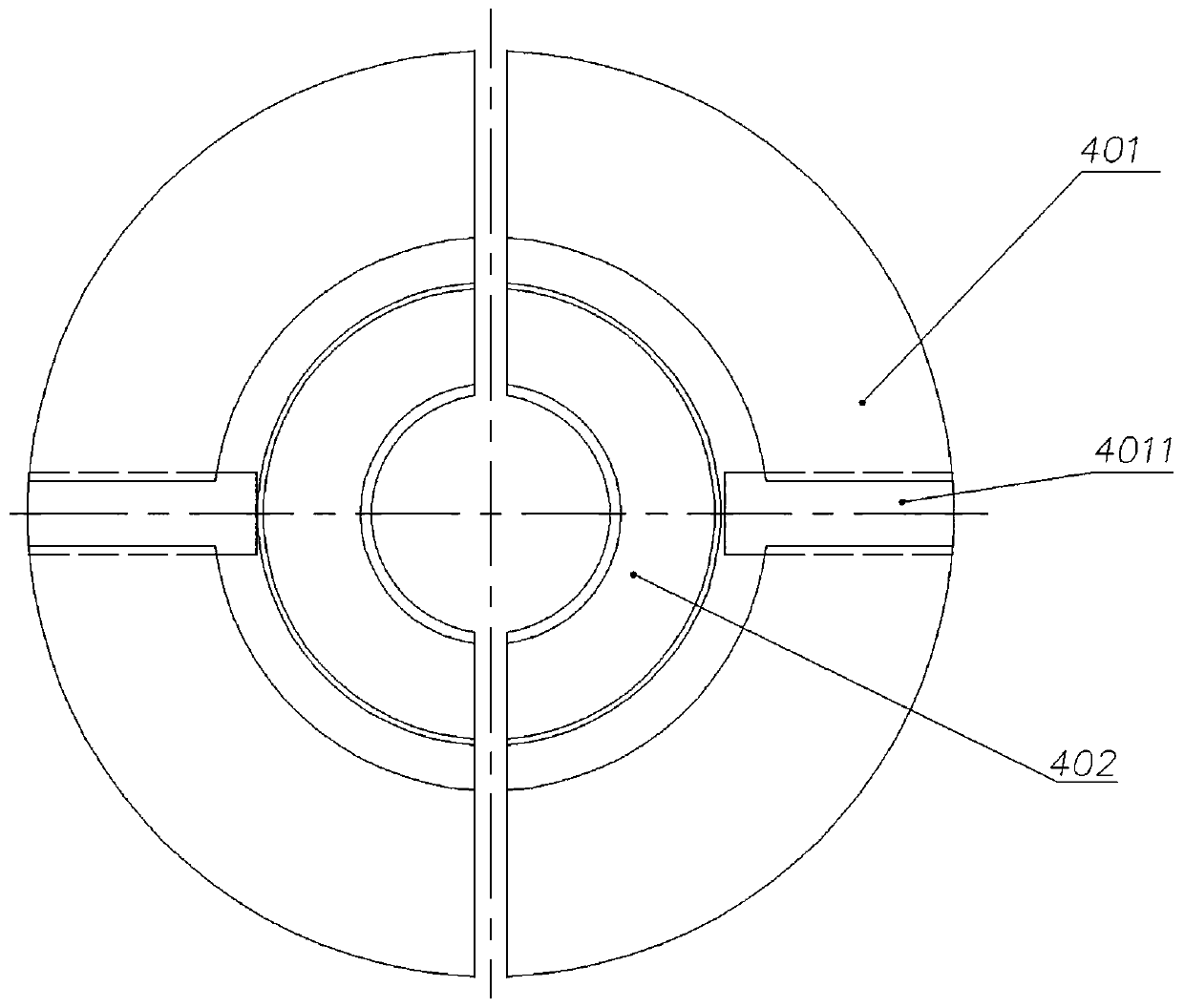

[0032] refer to figure 2 and image 3 , the slip body assembly 4 is a split type, including two slip bodies 401 and slips 402 respectively fixed in each slip body 401; each slip body 401 is provided with a dovetail-shaped guide key on the conical surface 3 fit the dovetail groove 4011.

[0033] refer to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com