Self-locking hydraulic cylinder

A hydraulic cylinder and self-locking technology, applied in the field of hydraulic cylinders, can solve the problems of inconvenient maintenance and use, more oil circuits, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

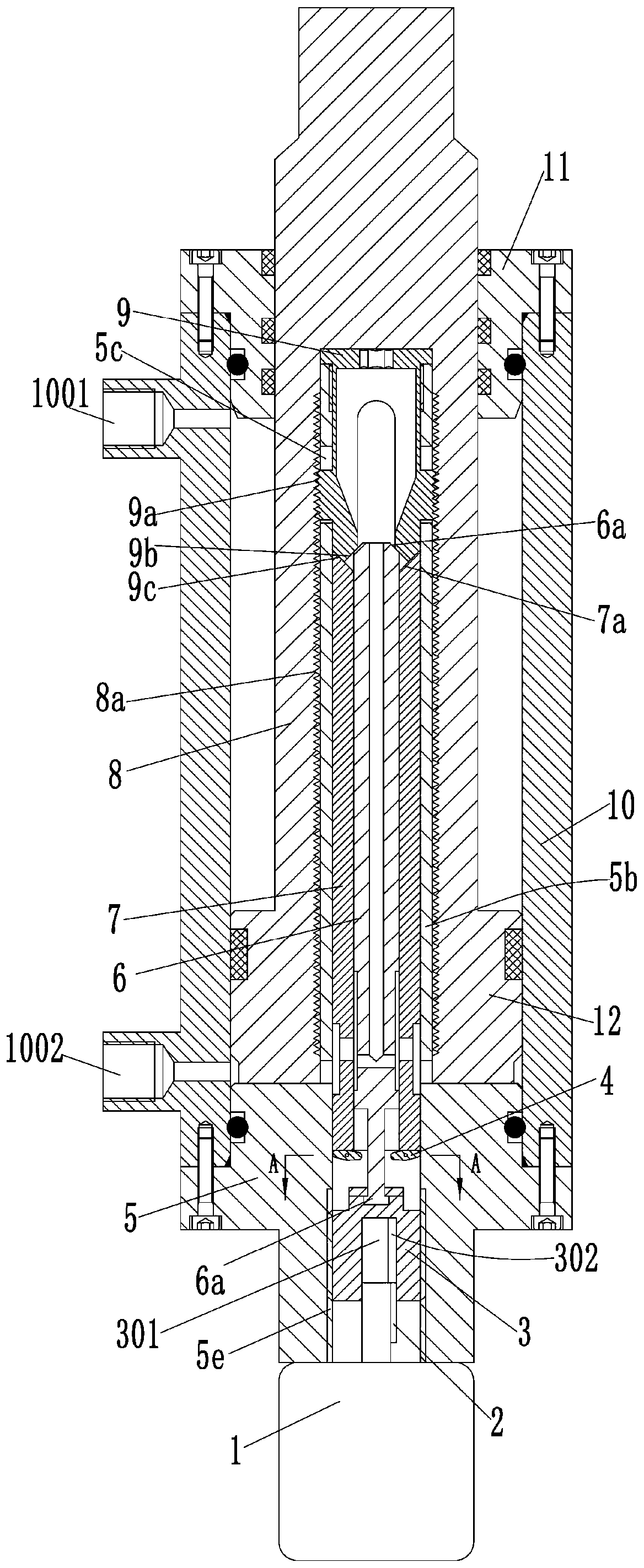

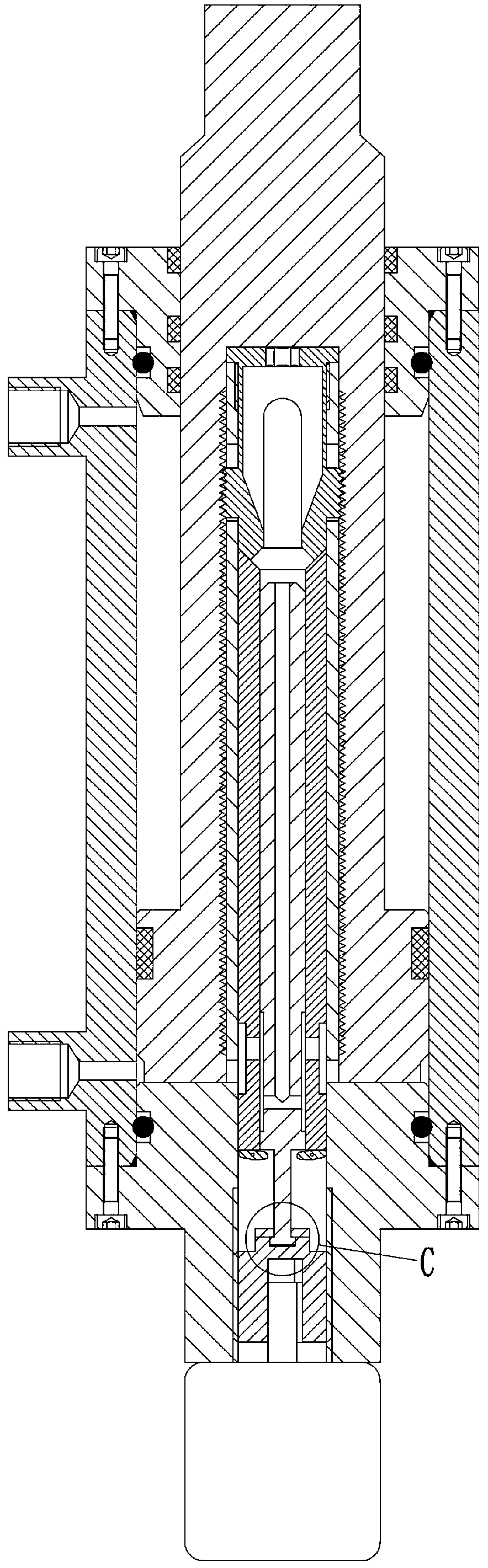

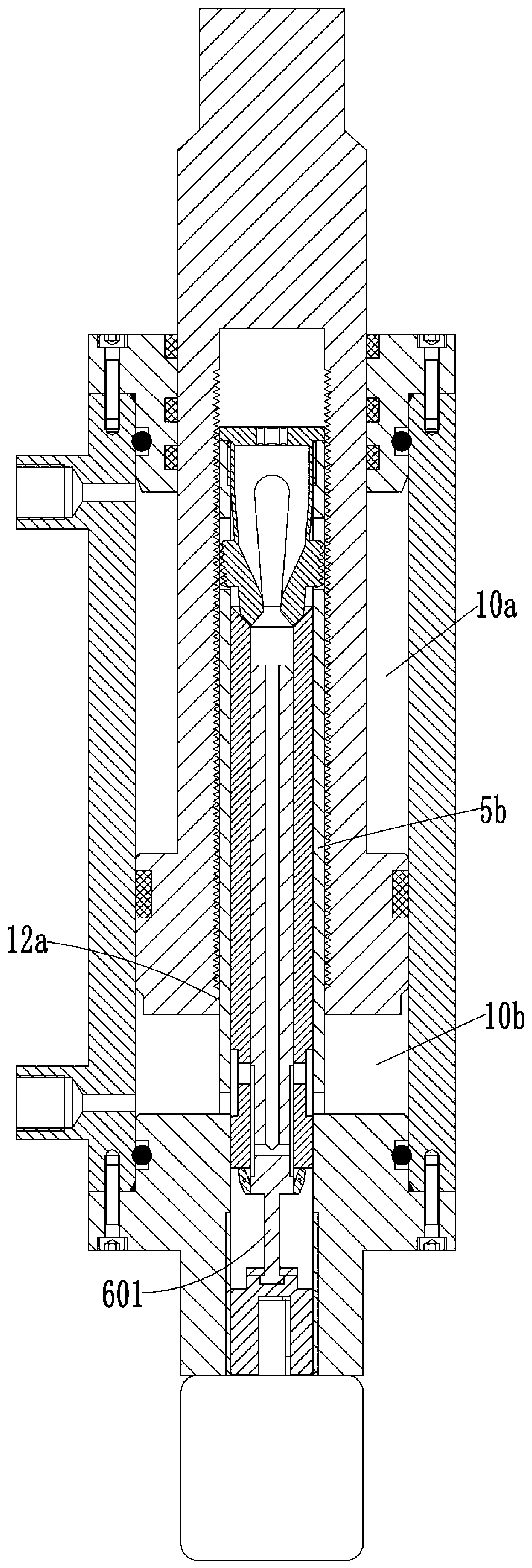

[0024] see Figure 1-9 As shown, a self-locking hydraulic cylinder includes a cylinder body 10, an upper end cover 11 is fixedly installed on the upper end of the cylinder body 10, and a lower end cover 5 is fixedly installed on the lower end; a piston body 12 is slidably connected in the cylinder body 10, The piston body 12 is provided with a piston rod 8 passing through the upper end cover 11, and the piston rod 8 is slidably connected with the upper end cover 11; a rod cavity 10a is formed between the upper end cover 11 and the piston body 12, and the lower end cover 5 and the piston body 12 form a rodless chamber 10b; the side of the cylinder body 10 is provided with an A port 1001 communicating with the rod chamber 10a and a B port 1002 communicating with the rodless chamber 10b; the lower end cover 5 A self-locking mechanism is provided inside, and the self-locking mechanism can realize the locking of the piston rod 8 when the piston rod 8 moves to any position.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com