A filter membrane clamping device with self-locking shock-absorbing function

A clamping device and filter membrane technology, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of poor stability and shock absorption, large overall weight and volume, and no shock absorption function, etc. problem, to achieve the effect of preventing movement and falling off, low production cost, and good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, structural composition and working principle of the present invention are described as follows:

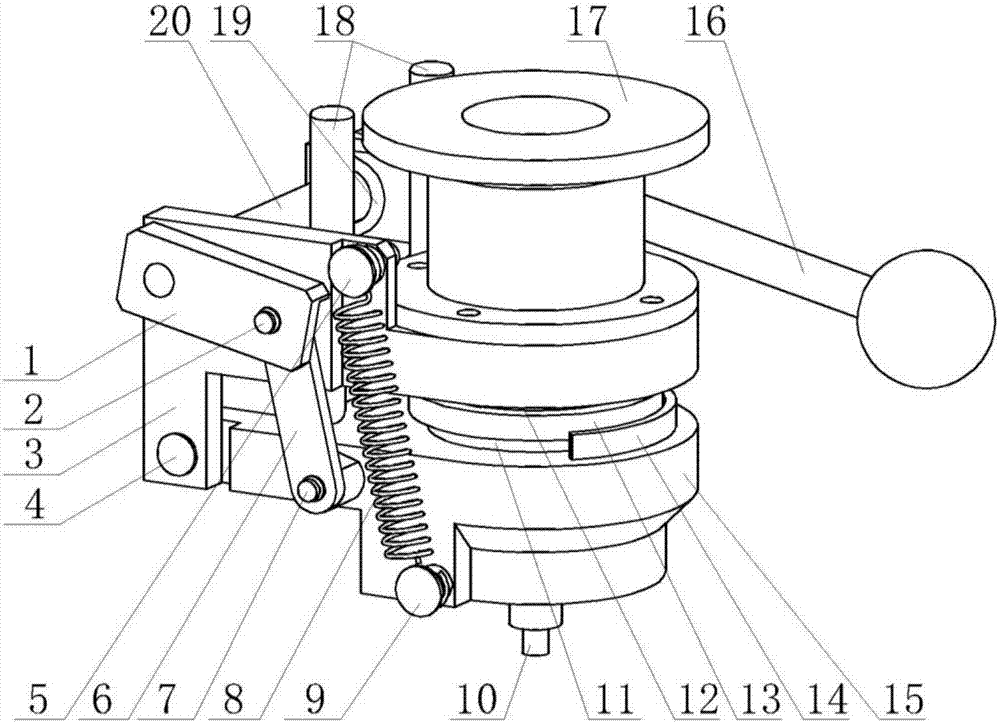

[0025] Such as figure 1 As shown, a filter membrane clamping device with self-locking damping function includes: crank 1, crank shaft 2, fixed seat 3, rocker shaft 4, spring upper hook 5, connecting rod 6, connecting rod shaft 7, spring 8 , spring lower hook 9, air extraction nozzle 10, lower sealing ring 11, upper sealing ring 12, filter membrane 13, limit seat 14, rocker 15, handle 16, air intake seat 17, damper 18, bearing 19, main Revolving shaft 20. The crank 1 and the handle 16 are rigidly connected with the main shaft 20, so that the swing handle 16 can drive the main shaft 20 to rotate, thereby driving the crank 1 to swing; The rod 6 rotates around the crank shaft 2, and the overlapping part of the crank 1 and the connecting rod 6 has a limit groove to ensure that the connecting rod 6 cannot continue to rotate after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com