Display panel, manufacturing method and display device

A technology for display panels and manufacturing methods, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor cost, thickened display device viewing angle compensation effect, etc., to achieve reduced box thickness, good viewing angle compensation effect, and orientation effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, The features and their functions are detailed as follows:

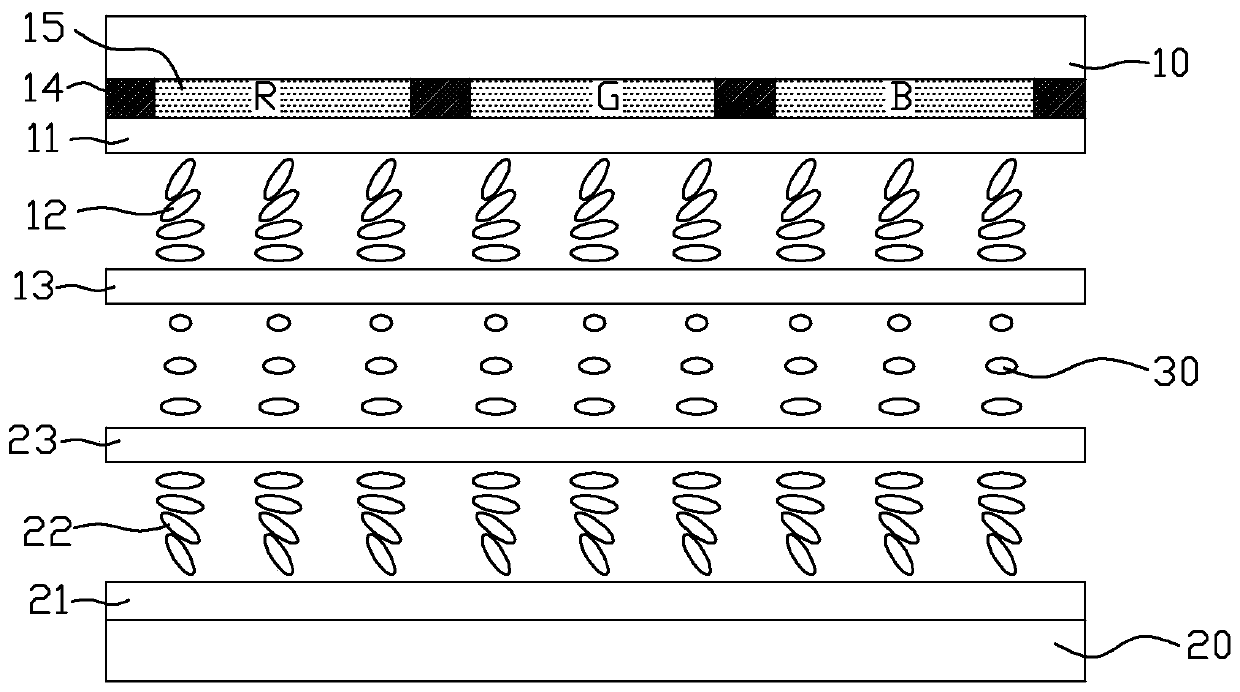

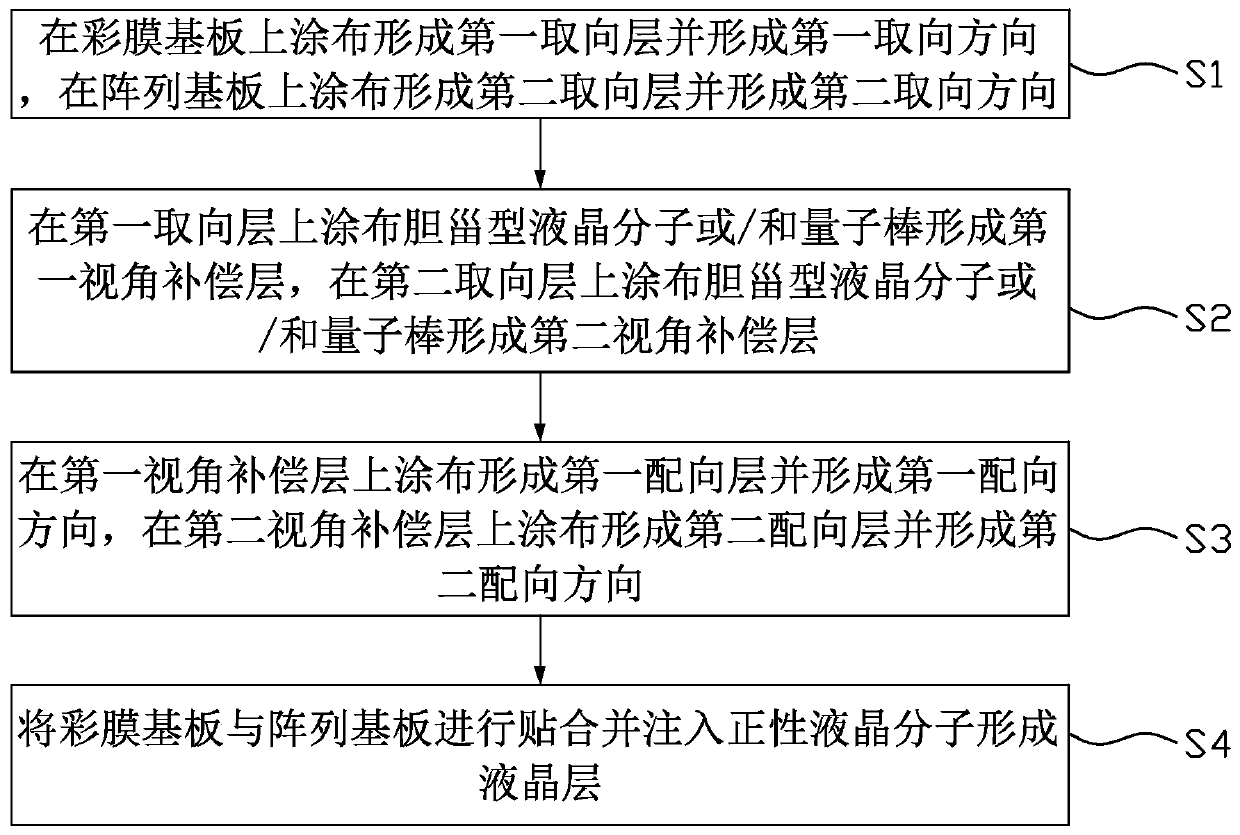

[0026] figure 1 is a schematic structural diagram of a display panel in an embodiment of the present invention, figure 2 is a flow chart of a method for manufacturing a display panel in an embodiment of the present invention, Figures 3a-3c It is a structural schematic diagram of the manufacturing process of the color filter substrate of the display panel in an embodiment of the present invention, Figures 4a-4c It is a structural schematic diagram of the manufacturing process of the array substrate of the display panel in an embodiment of the present invention.

[0027] Such as figure 1 As shown, the display panel provided by the present invention includes a color filter substrate 10, an array substrate 20 disposed opposite to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com