Liquid crystal display panel and manufacturing method thereof

A technology for a liquid crystal display panel and a manufacturing method, applied in optics, instruments, nonlinear optics, etc., can solve problems such as difficulty in meeting expected requirements and low yield, and achieve the effects of reducing cell thickness, speeding up response time, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

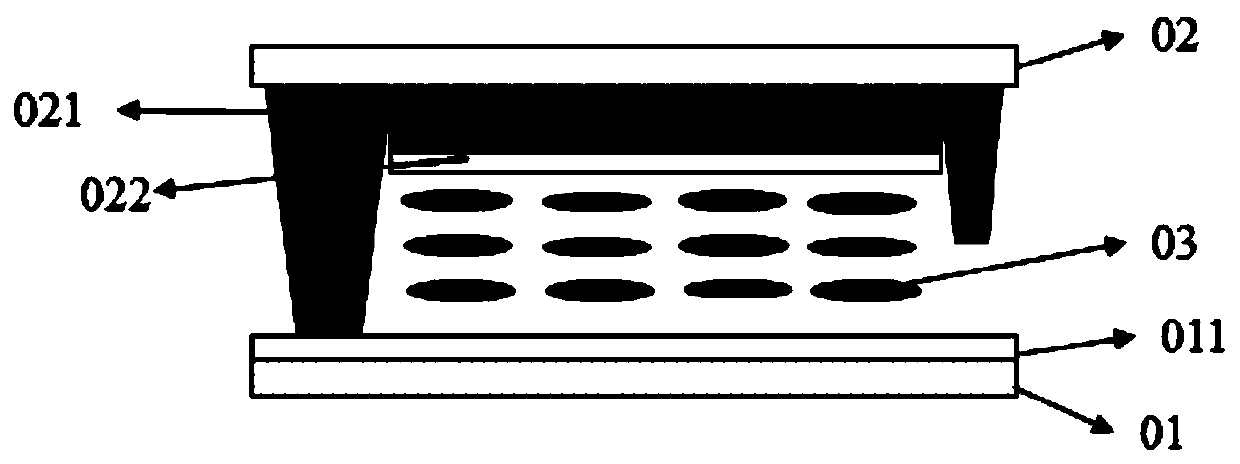

[0037] This embodiment discloses a method for manufacturing a liquid crystal display panel. The manufactured liquid crystal display panel is as follows: figure 1 Shown, for FFS / IPS display mode. The liquid crystal display panel includes an array substrate 01, a color filter substrate 02, and a liquid crystal 03 located between the array substrate 01 and the color filter substrate 02, wherein the array substrate 01 is an array substrate conforming to a conventional FFS / IPS display mode, and the color filter The substrate 02 is a color filter substrate conforming to the conventional FFS / IPS display mode, and the liquid crystal 03 is a positive liquid crystal or a negative liquid crystal, wherein, because the liquid crystal display panel is suitable for the FFS / IPS display mode, the liquid crystal 03 in the display panel Arranged horizontally. The preparation method comprises the following steps:

[0038] S1: Coating an alignment liquid on the side of the array substrate 01 opp...

Embodiment 2

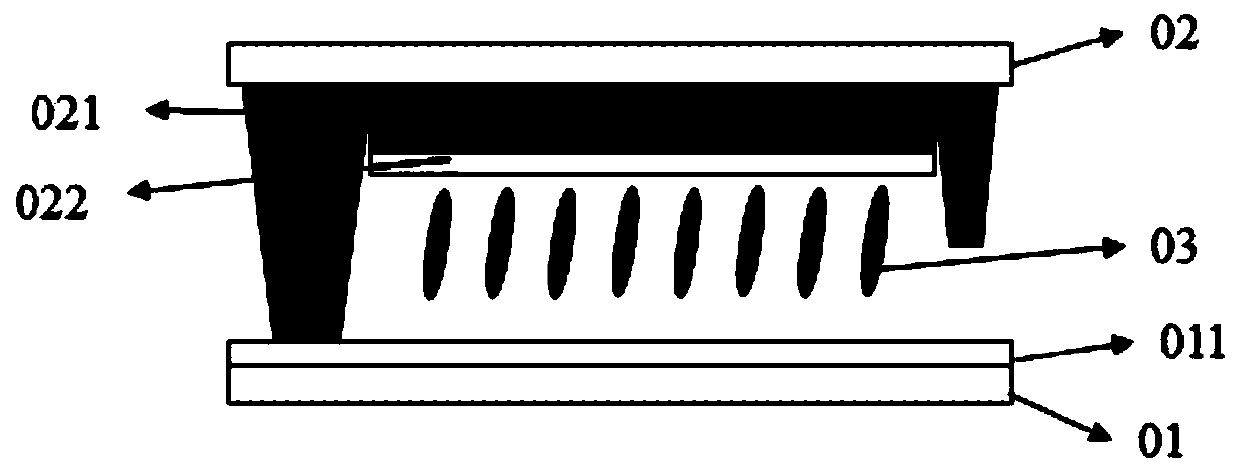

[0043]This embodiment discloses a method for manufacturing a liquid crystal display panel. The manufactured liquid crystal display panel is as follows: figure 2 shown, for VA display mode. The liquid crystal display panel includes an array substrate 01, a color filter substrate 02, and a liquid crystal 03 located between the array substrate 01 and the color filter substrate 02, wherein the array substrate 01 is an array substrate conforming to a conventional VA display mode, and the color filter substrate 02 In order to comply with the color filter substrate of the conventional VA display mode, the liquid crystal 03 is a negative liquid crystal, wherein, because the liquid crystal display panel is suitable for the VA display mode, the liquid crystal 03 in the display panel is arranged vertically. The preparation method comprises the following steps:

[0044] S1: Coating an alignment liquid on the side of the array substrate 01 opposite to the color filter substrate 02 to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com