Phase shifter, manufacturing method and working method thereof

A production method and a technology of working method, which are applied in the field of phase shifters, can solve the problems of limited response time and low phase shift degree, and achieve the effect of reducing response time and increasing phase shift degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following detailed description will be given in conjunction with the accompanying drawings and specific embodiments.

[0051] Embodiments of the present invention provide a phase shifter, a manufacturing method and a working method thereof, which can not only reduce the response time of the phase shifter but also increase the phase shift degree of the phase shifter.

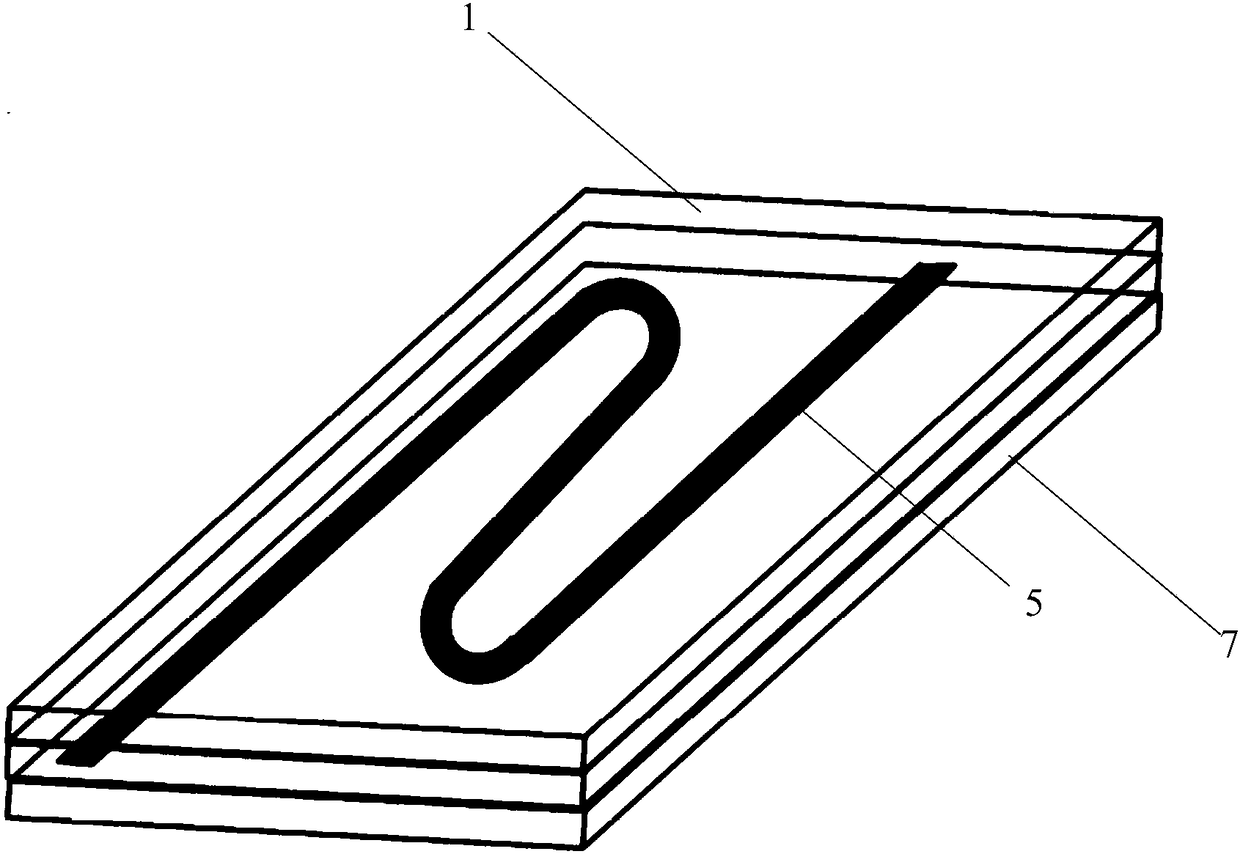

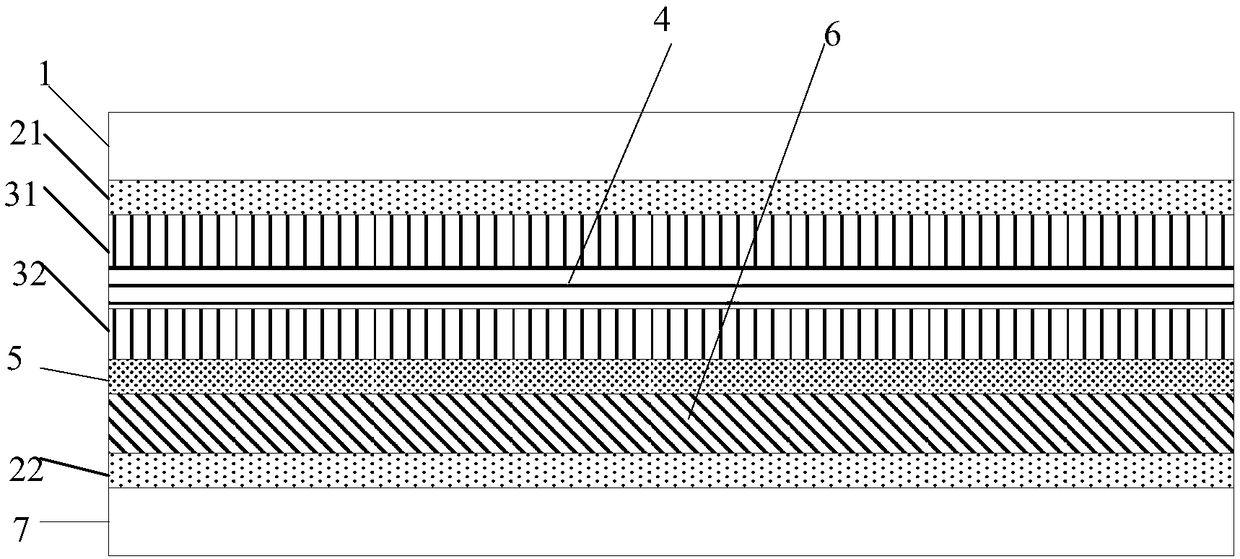

[0052] An embodiment of the present invention provides a phase shifter, including a first sub-phase shifter and a second sub-phase shifter arranged in layers, the first sub-phase shifter and the second sub-phase shifter multiplexing the same a microstrip line, and the microstrip line is located between the first sub-phase shifter and the second sub-phase shifter.

[0053] In this embodiment, the phase shifter is composed of a first sub-phase shifter and a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com