Time prediction and optimization method for complex product development based on design structure matrix

A technology for designing structure matrix and complex products, applied in the field of complex product development time prediction and optimization, it can solve the problems of insufficient high-level rework research, inability to rework effective analysis and optimization, etc., so as to reduce the total product development time and improve product development. Success rate, the effect of increasing persuasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0138] The present invention will be described in detail below with reference to the accompanying drawings.

[0139] A complex product development time prediction and optimization method based on design structure matrix, including the following steps:

[0140] 1. Build the optimization objective function (total time for the product development project):

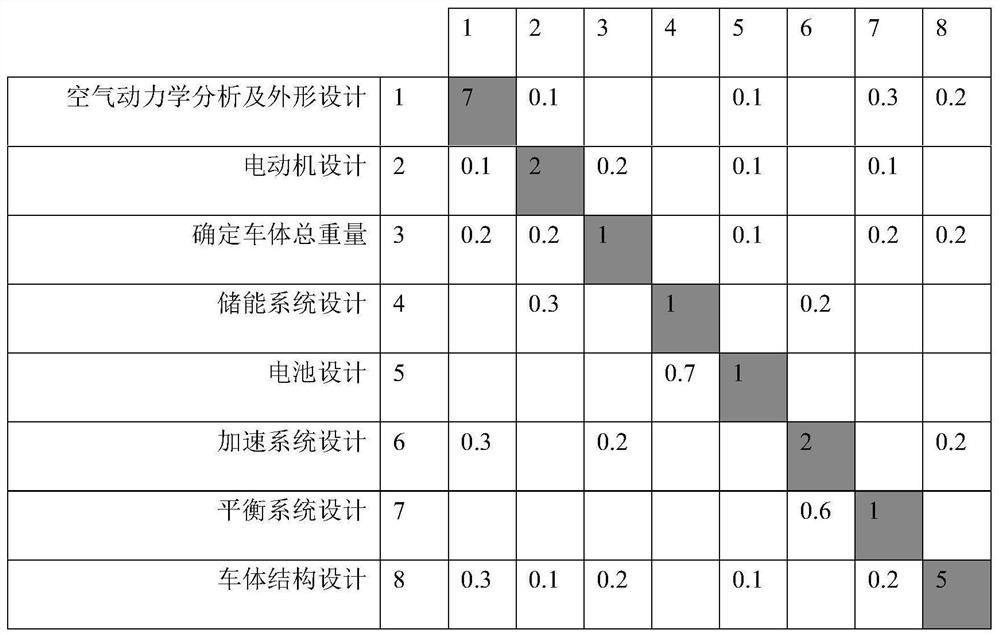

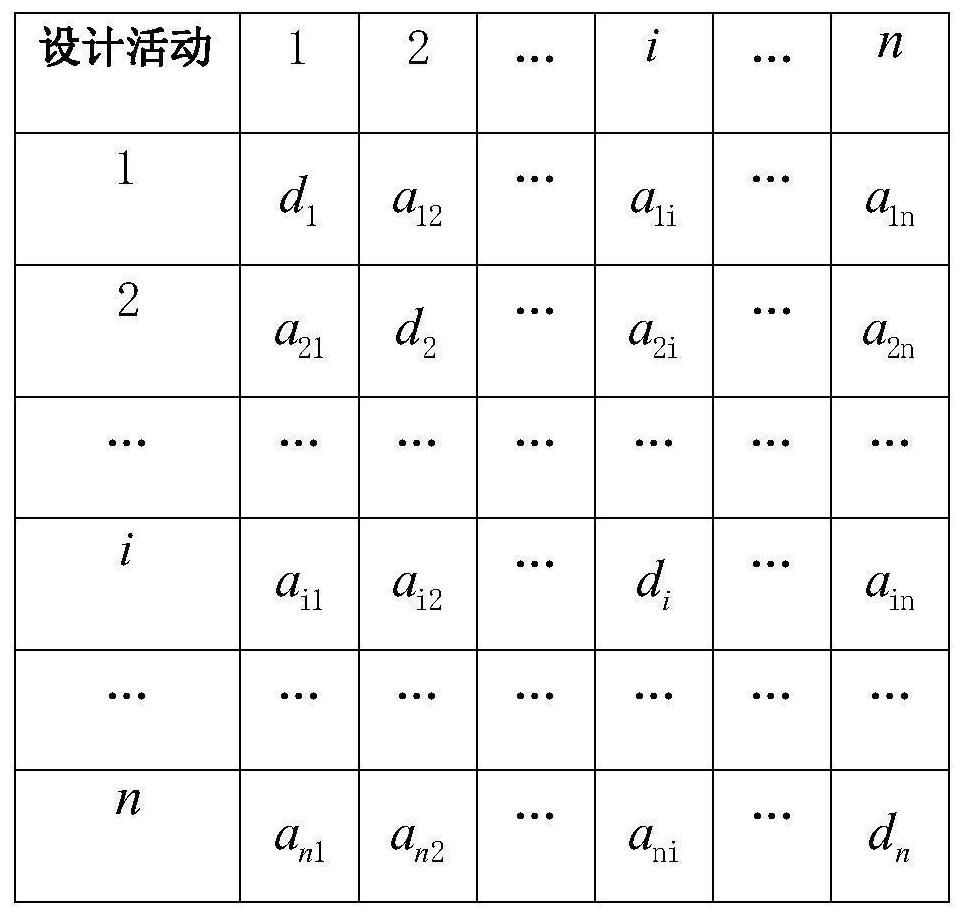

[0141] First, for a complex product development process consisting of n design activities with known average completion time and known information dependencies, all of its design activities form a set of design activities N. There are quite complex information dependencies between design activities. If the obtained information is incomplete or the obtained information changes, there will be a certain possibility of rework. According to the design activity set N, any product development project corresponding to the construction can be constructed. DSM matrix such as figure 2 shown. Among them, the diagonal element d in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com