CSP LED with round light-emitting surface and processing method of CSP LED

A processing method and technology of light-emitting surface, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of mass production of CSPLED, etc., and achieve the effect of novel and unique processing method, convenient light distribution, and good visual effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

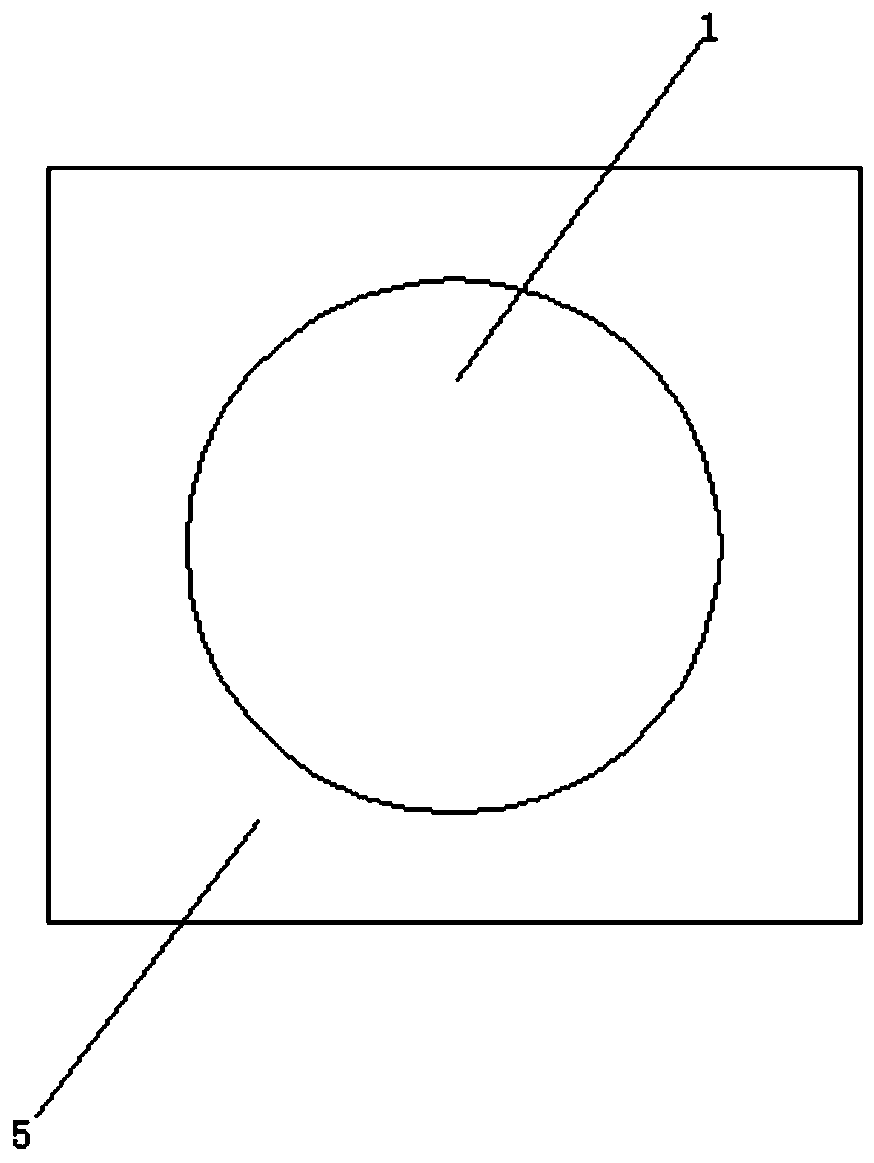

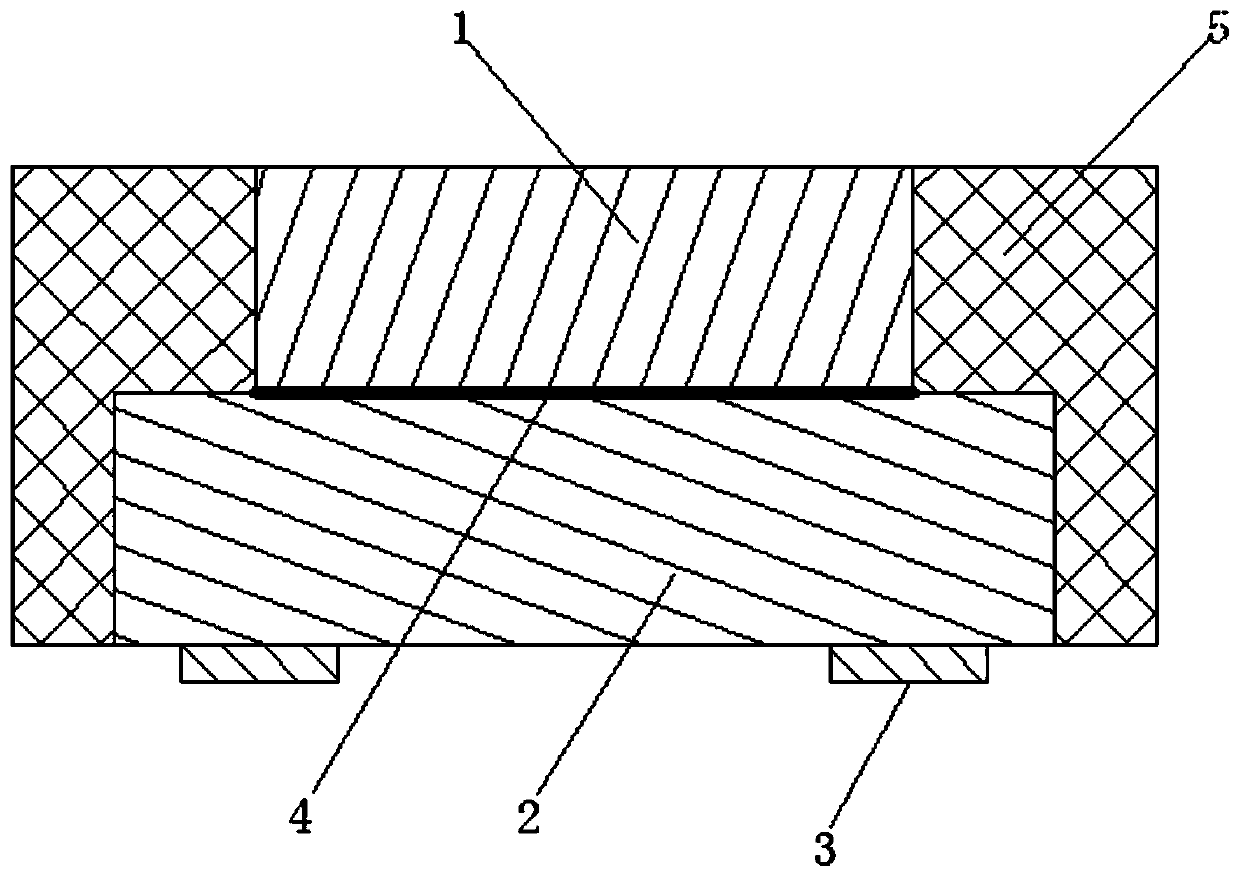

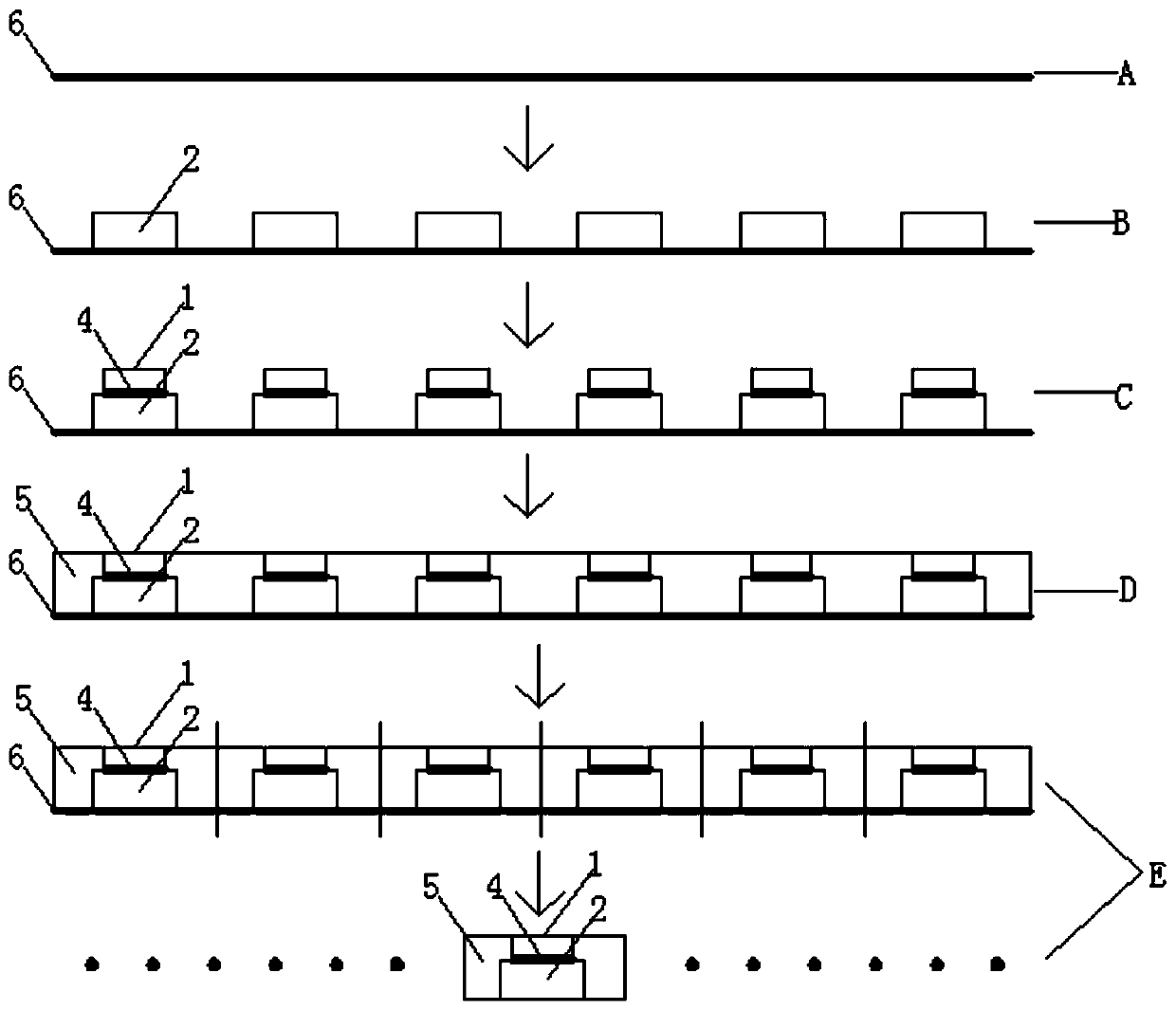

[0022] combine figure 1 with figure 2 , this embodiment is a CSP LED with a circular light-emitting surface, including a fluorescent film 1 and an LED chip 2 that are separated and fixed up and down, the fluorescent film 1 is circular, and the lower wall of the LED chip 2 is provided with a pair of electrodes 3, An adhesive layer 4 is sandwiched between the LED chip 2 and the fluorescent film 1, the upper wall of the LED chip 2 covers the lower wall of the fluorescent film 1, and white wall glue 5 is wrapped around the LED chip 2 and the fluorescent film 1, forming a whole A rectangular parallelepiped with the plane where the upper wall of the fluorescent film 1 is located as the top surface and the plane where the lower wall of the LED chip 2 is located as the bottom surface.

[0023] This embodiment is a CSP LED that emits light from one side, and its l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com