Patents

Literature

36results about How to "Great industrial value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

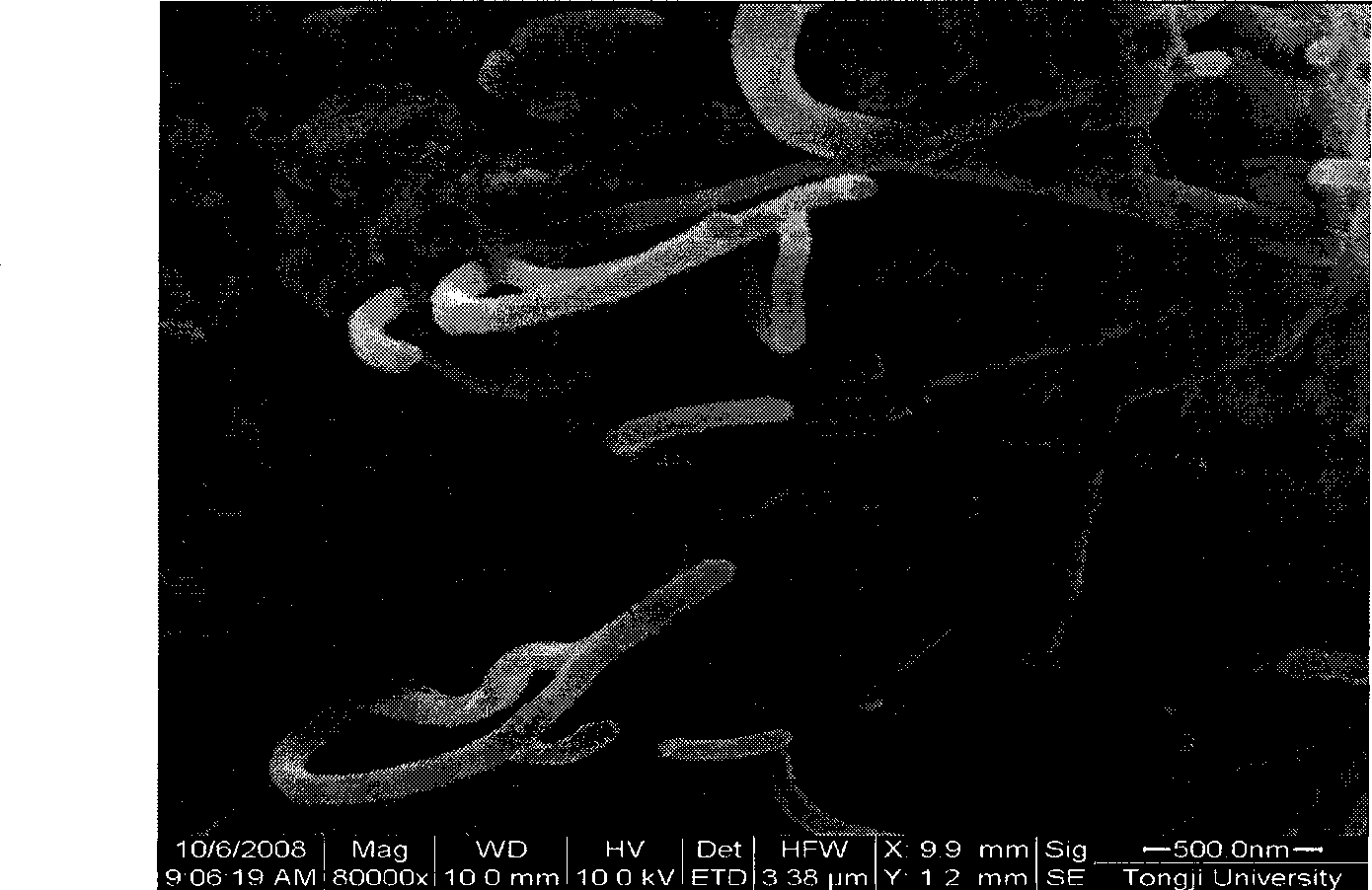

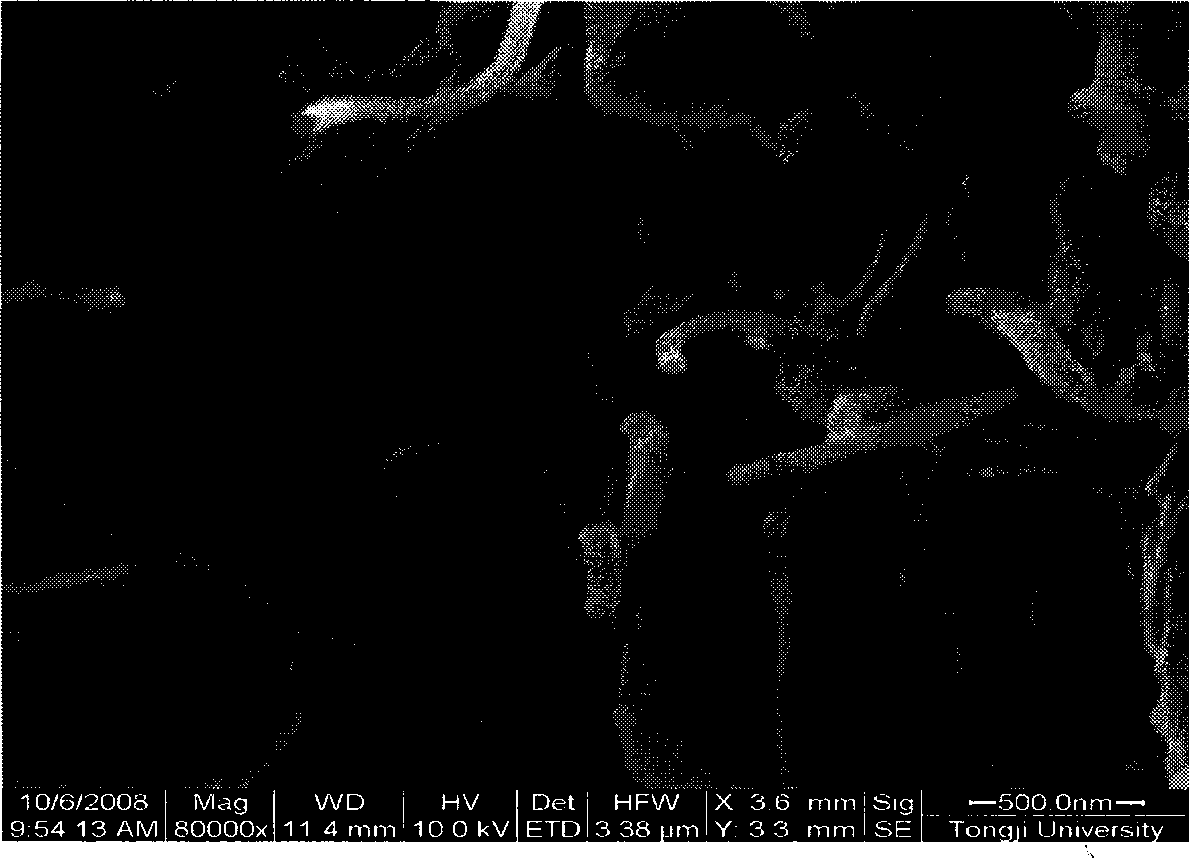

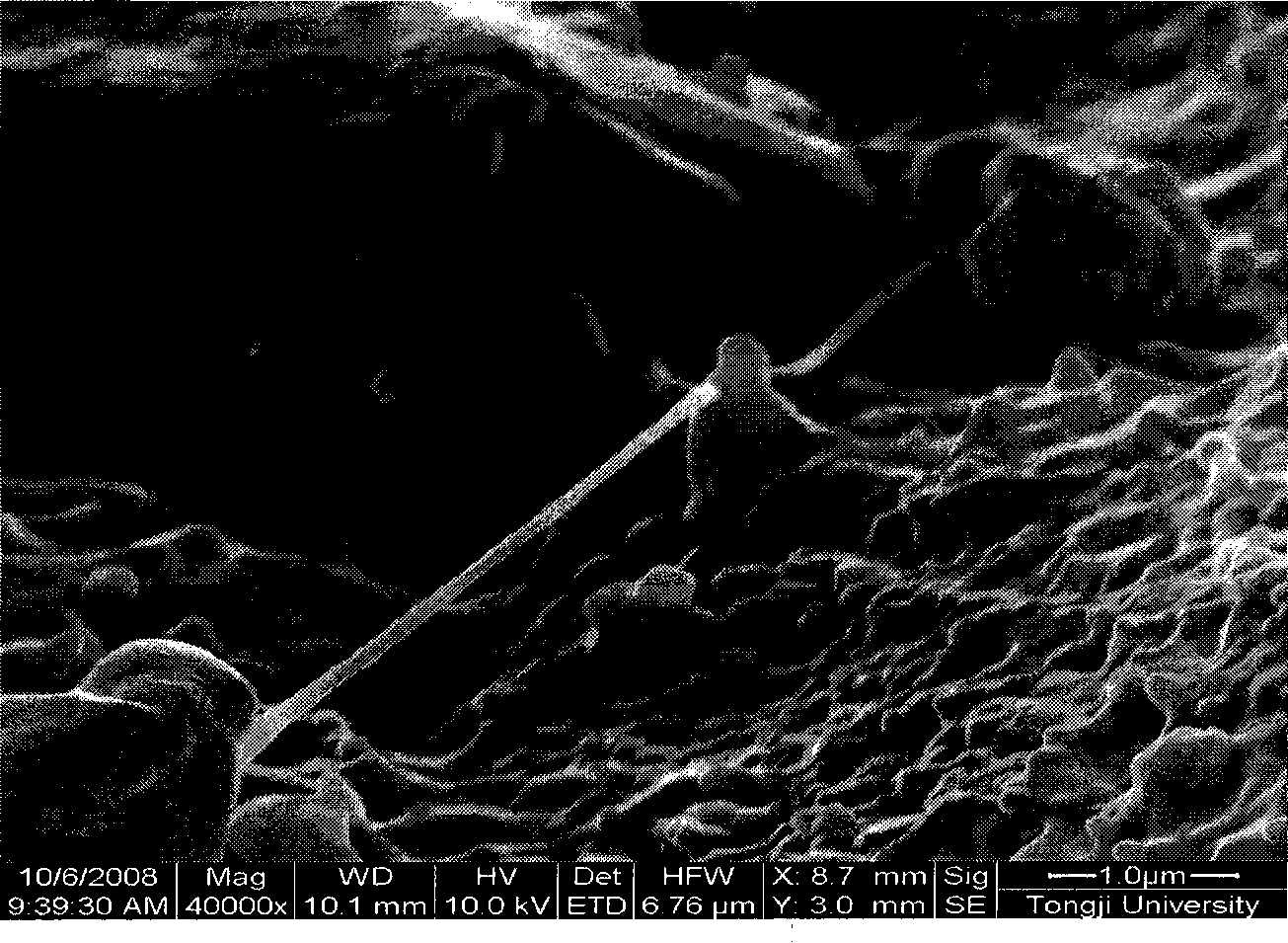

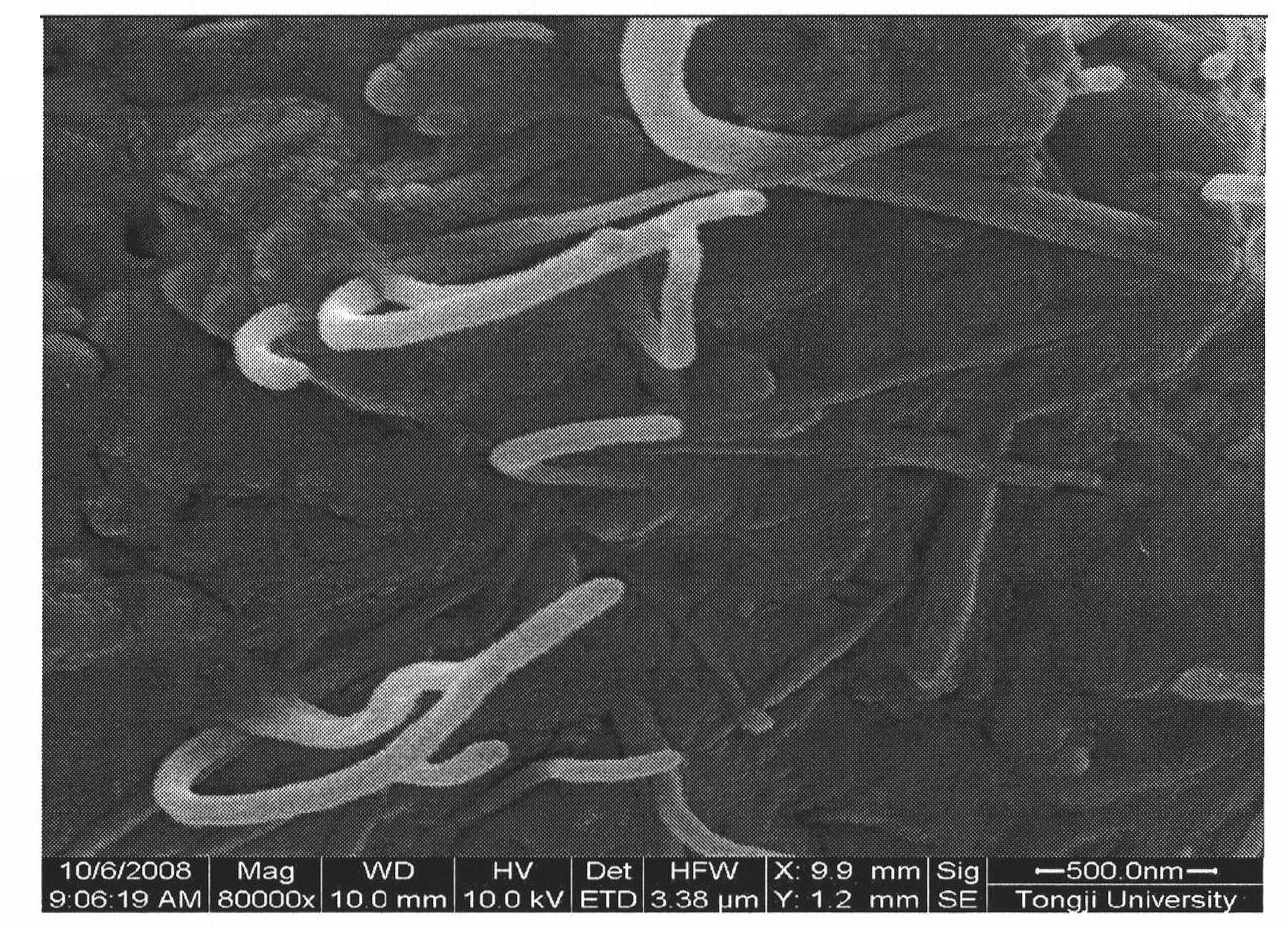

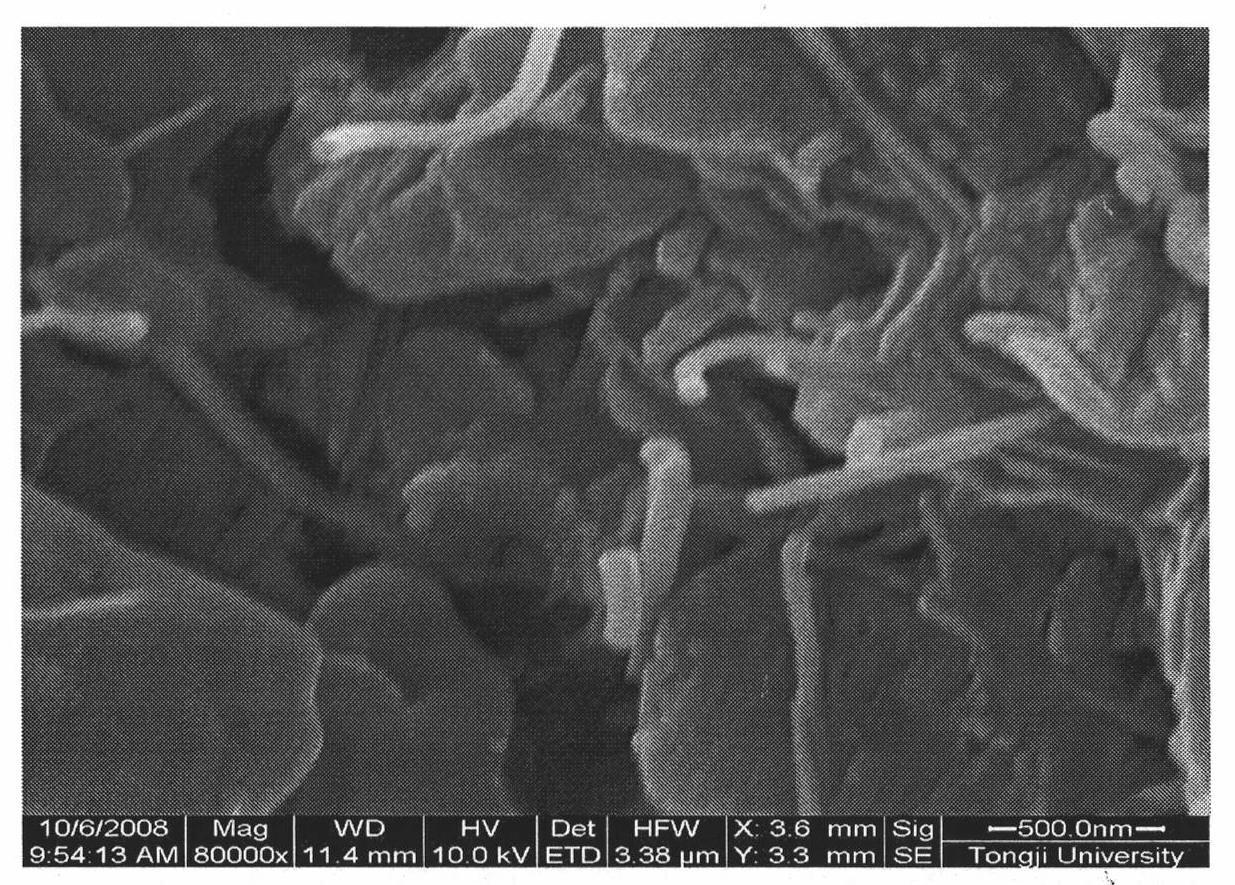

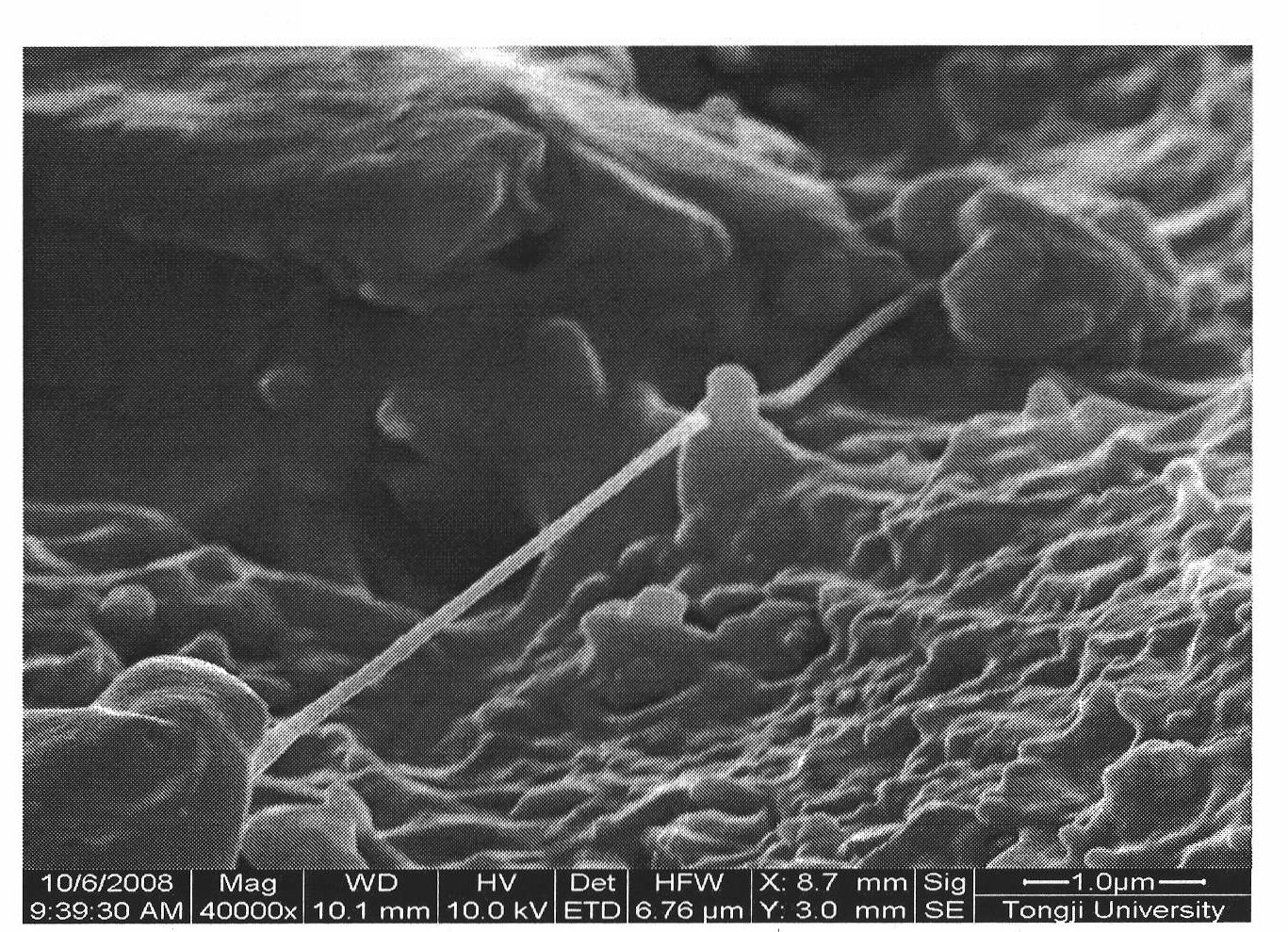

Process for producing high-strength high-ductility hard polyvinyl chloride

This invention pertains to the field of material technology, in particular relates to a preparation method of high strength and high tenacity rigid polyvinyl chloride. The specific steps are as follows: mixing a carbon nano tube with concentrated nitric acid under certain conditions for obtaining an acidulated carbon nano tube; mixing the acidulated carbon nano tube with SOCl2 for obtaining the carbon nano tube with an acyl chloride group; and then mixing polycaprolactone with the carbon nano tube with the acyl chloride group for obtaining the carbon nano tube of polycaprolactone chemical grafting. Polyvinyl chloride power, plasticizing agent, composite stabilizer, filling agent, whitening agent, lubricating agent and the carbon nano tube are pre-mixed in certain proportion in a high-speed mixer, and then a dual-roller mill is used for plasticizing and finally the high strength and high tenacity rigid polyvinyl chloride is obtained by rolling under certain pressure. The invention has the advantages of available raw materials, simple process, using existing industrial equipment of polyvinyl chloride, relatively low price, excellent product performances and important application value.

Owner:TONGJI UNIV

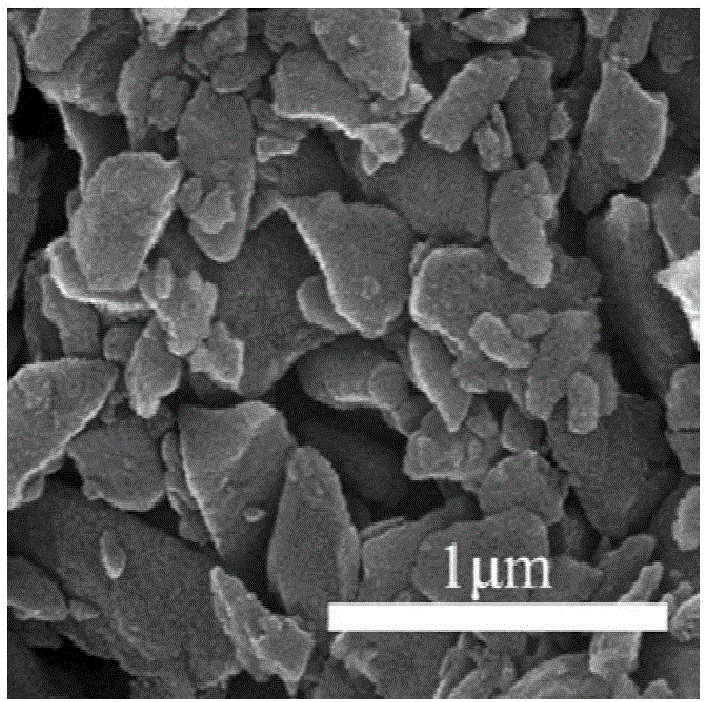

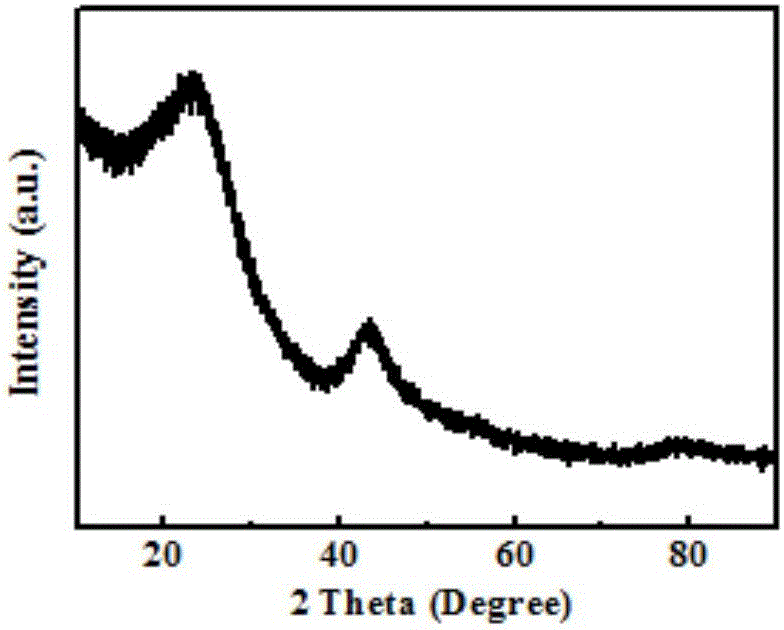

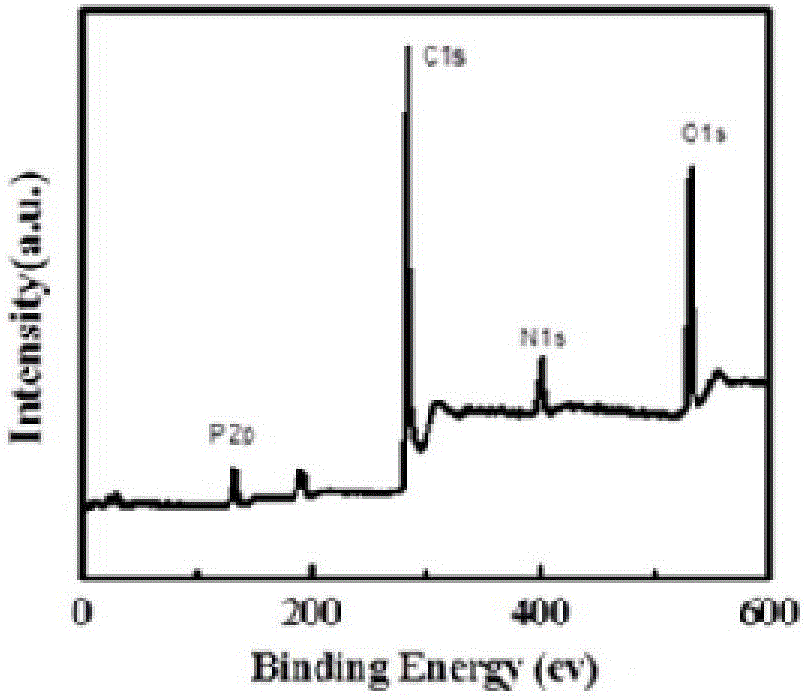

Flake-shaped nitrogen and phosphorus co-doped porous carbon material as well as preparation method and application thereof

ActiveCN106744794AGood electrical propertiesGood application prospectHybrid capacitor electrodesConductive materialPorous carbonDistillation

The invention provides a flake-shaped nitrogen and phosphorus co-doped porous carbon material. The flake-shaped nitrogen and phosphorus co-doped porous carbon material is prepared by the following method: mixing aniline and phosphonitrilic chloride trimer and sealing and reacting for 2h to 24h under the conditions that the pressure is 1MPa to 10MPa and the temperature is 140 DEG C to 260 DEG C; then releasing pressure to normal pressure and drying by distillation to obtain a solid substance; under the protection of inert gas, carrying out high-temperature treatment on the solid substance at 400 DEG C to 1000 DEG C for 1h to 6h, so as to obtain a finished product. The flake-shaped nitrogen and phosphorus co-doped porous carbon material provided by the invention has excellent electric properties and can be used for preparing a capacitor electrode, especially a super-capacitor electrode, so that the material can be used for a capacitor, especially a super-capacitor, and has extremely great application potential and industrial value in the field of energy storage.

Owner:WENZHOU UNIVERSITY

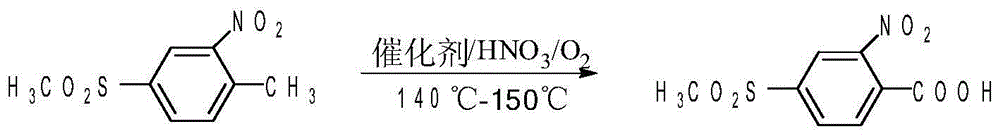

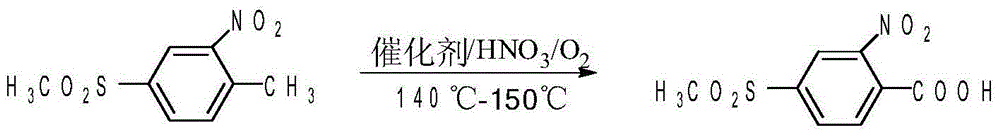

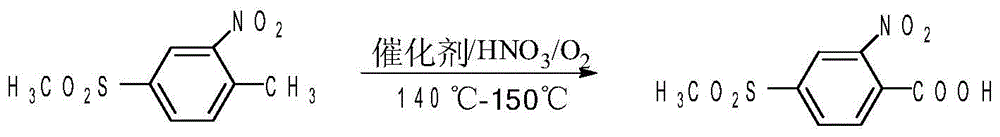

Method of preparing 2-nitro-4-methylsulfonyl benzoic acid

ActiveCN104557639AReduce usageHigh reaction yieldOrganic chemistryOrganic compound preparationBenzoic acidOxygen

The invention discloses a novel method of preparing 2-nitro-4-methylsulfonyl benzoic acid. The target product which is 2-nitro-4-methylsulfonyl benzoic acid is prepared by carrying out reaction by adopting an oxidation reaction device with a self-priming stirrer, wherein 2-nitro-4-methylsulfonyltoluene is used as the raw material, sulfuric acid is used as a reaction medium, a transition metal oxide is used as the catalyst, and oxygen is introduced in the course of reaction. The method provided by the invention has the advantage that the reaction condition is easy to control, the production cost is low, and the amount of the generated three wastes is reduced.

Owner:SHENYANG RES INST OF CHEM IND

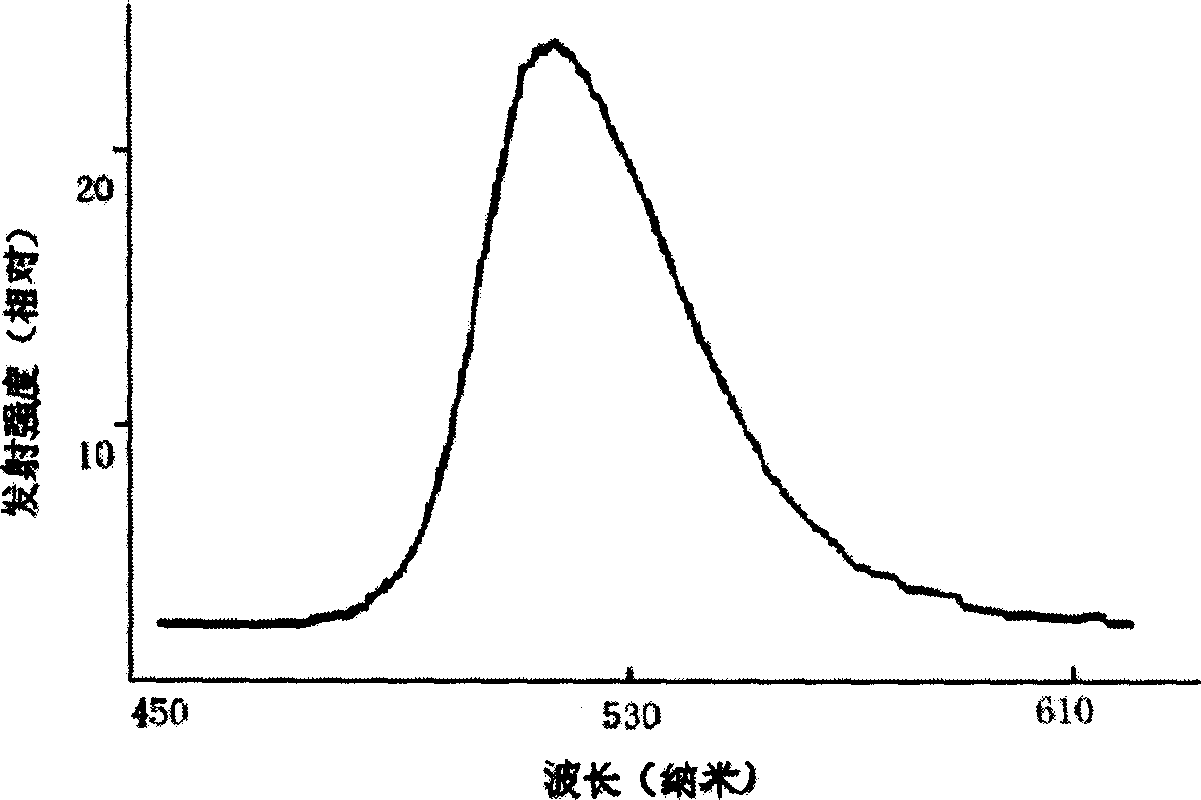

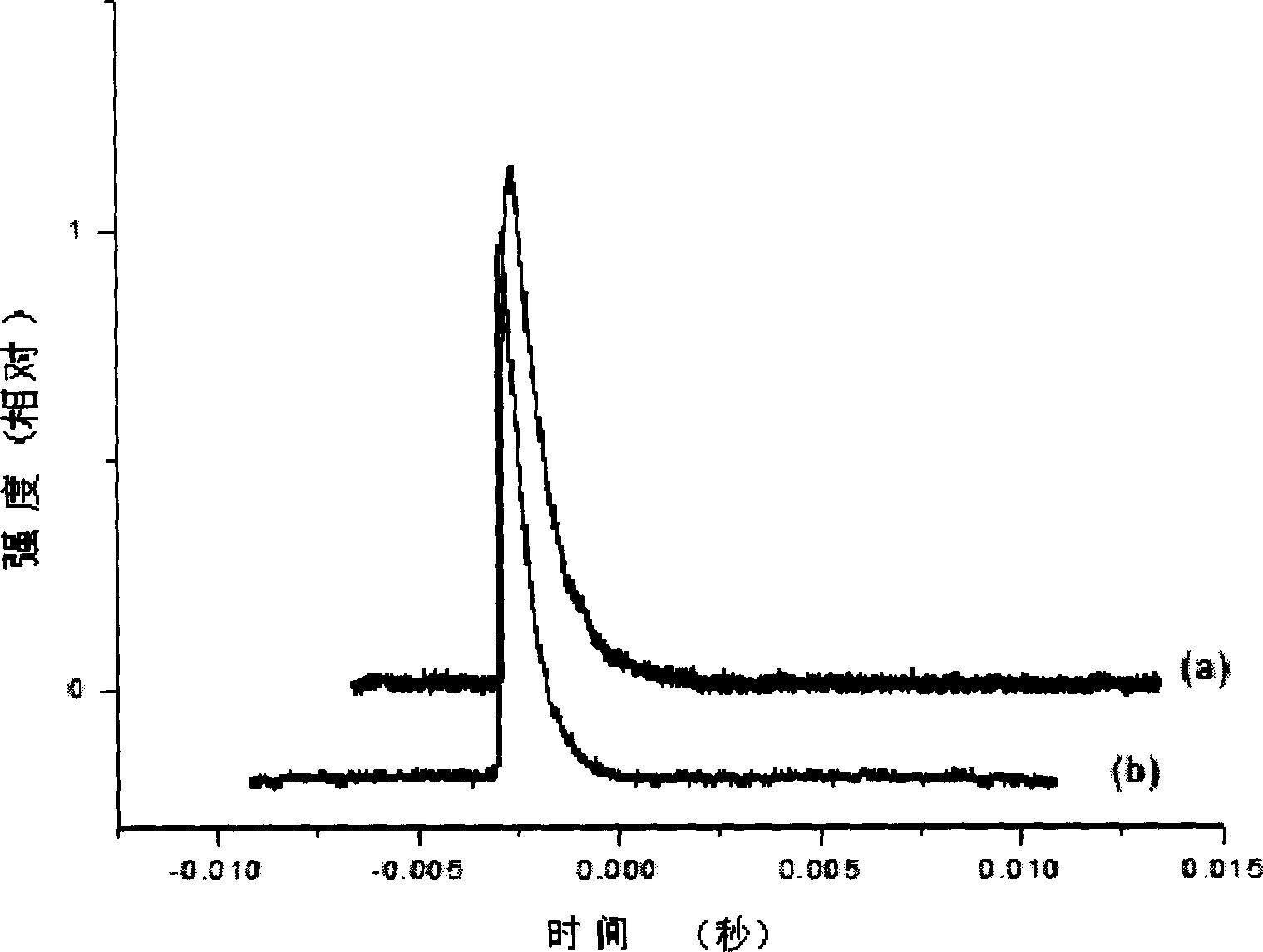

Short-afterglow zinc-manganese silicate green fluorescent powder and its preparing method

The invented fluorescent powder is obtained by using metal nitrate-organics combustion method through synthesis process, and its component is Zn2-2xSiO4:2xMn, X=0.0025-0.075; As compared with similarmanganese zinc silicate fluorescent powder synthesized by traditional method its fluorescent life is reduced to 4-8 ms from above 10 ms to eliminate the double-image effect of long after-glow, and its production process is simple, and said invented fluorescent powder is suitable for plasma display or cathode-ray display.

Owner:SUN YAT SEN UNIV

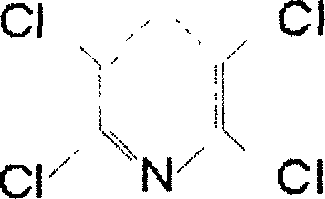

Process for preparing symmetric tetrachloro pyridine

InactiveCN1944408AIncrease conversion rate per passSimple processOrganic chemistryIron powderPyridine

The process of preparing symmetric tetrachloro pyridine includes the chlorination reaction of chloro pyridine containing 1-3 chlorine atoms and chlorine at 170-250 deg.c in the presence of iron powder or Lewis acid as catalyst for 8-48 hr. The preparation process uses chlorine in the liquid phase chlorination reaction to chlorinate chloropyridine, dichloropyridine, trichloropyridine, etc, and has single pass conversion rate up to 97 %, simple technological process, low production cost and excellent industrial application value.

Owner:盐城恒盛化工有限公司

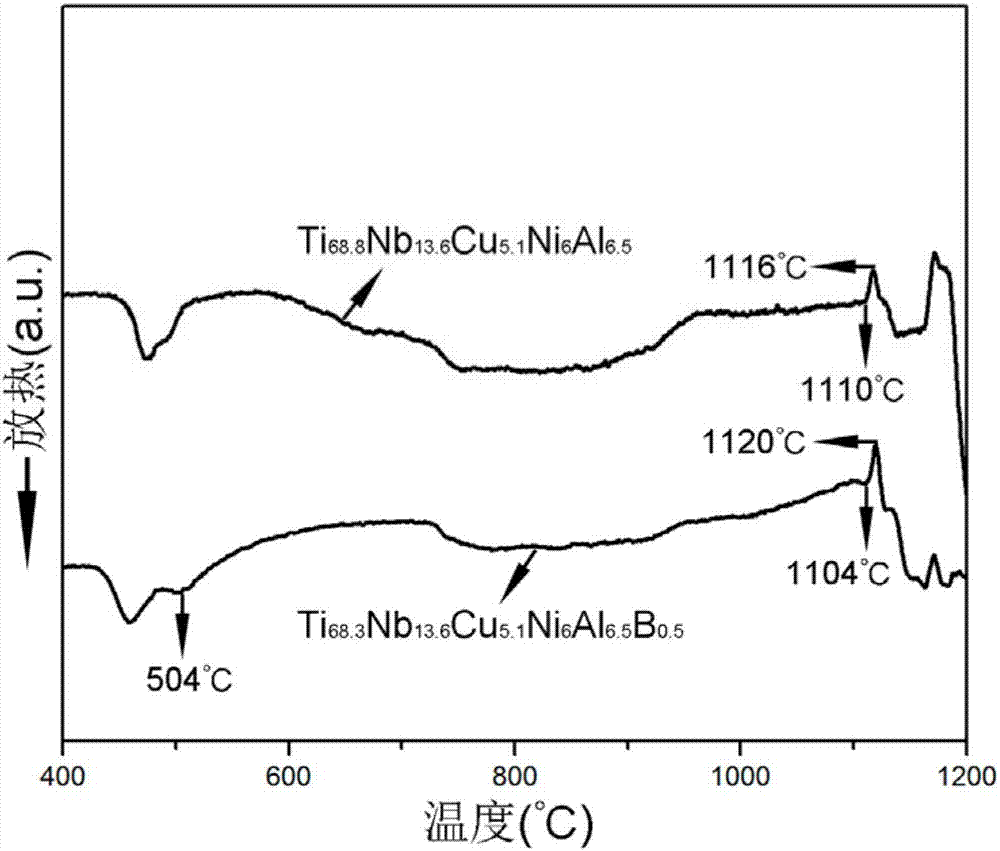

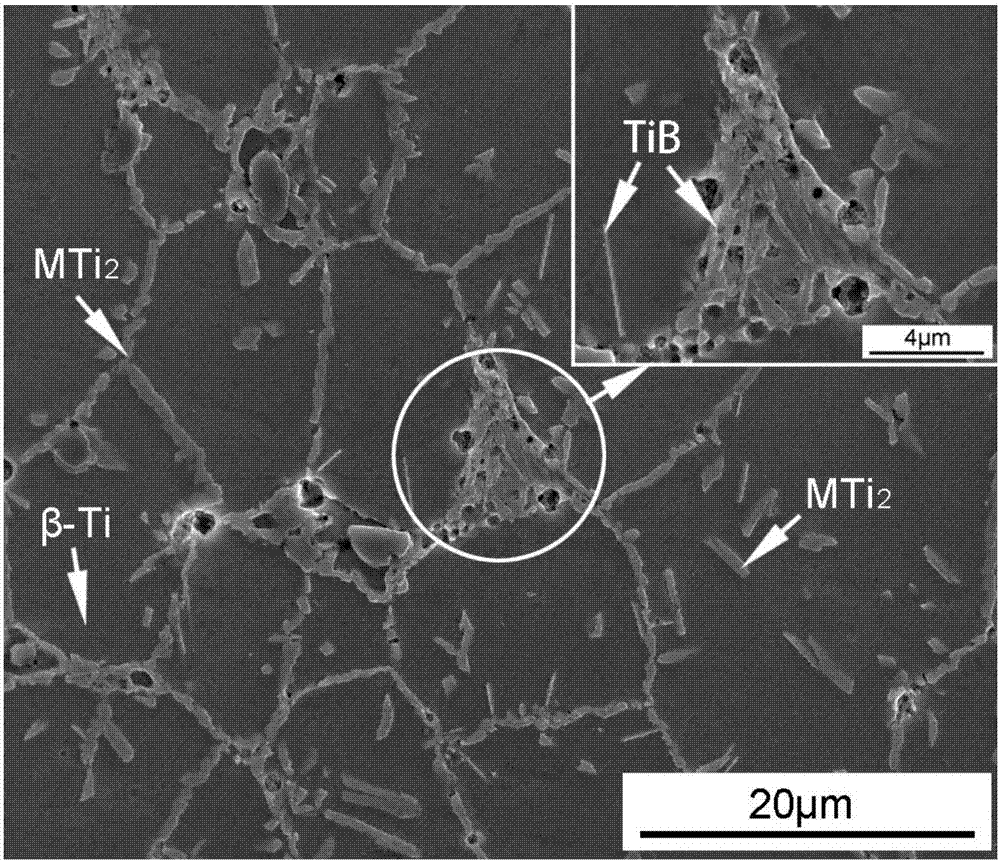

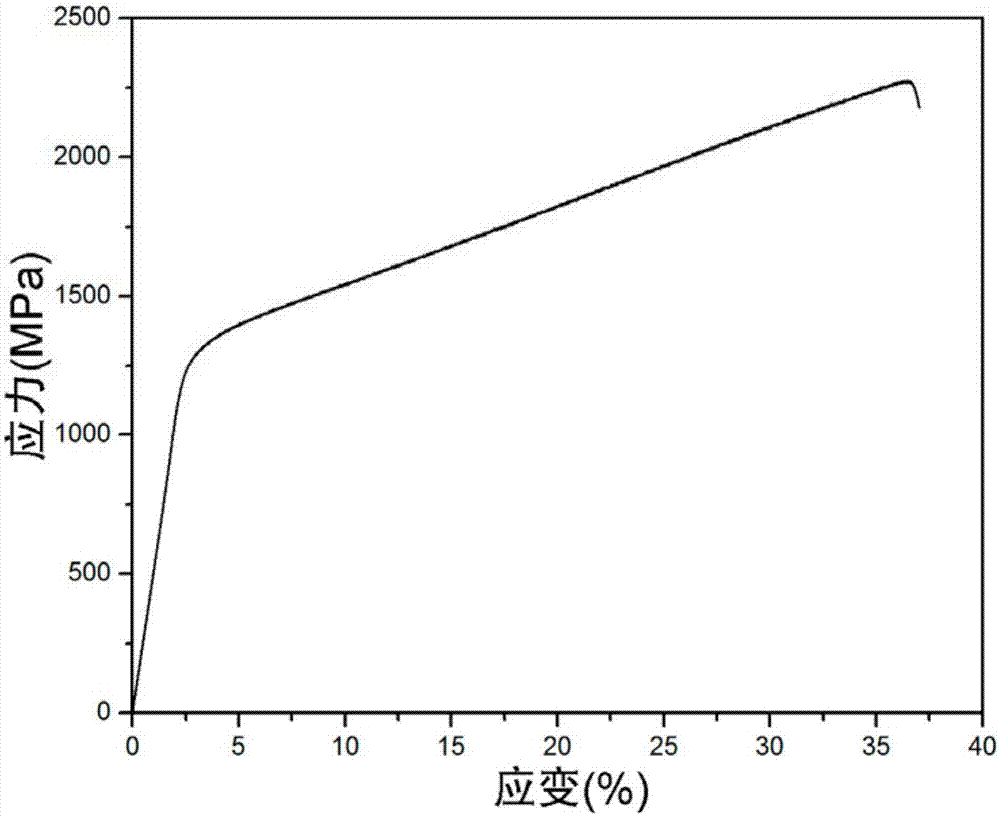

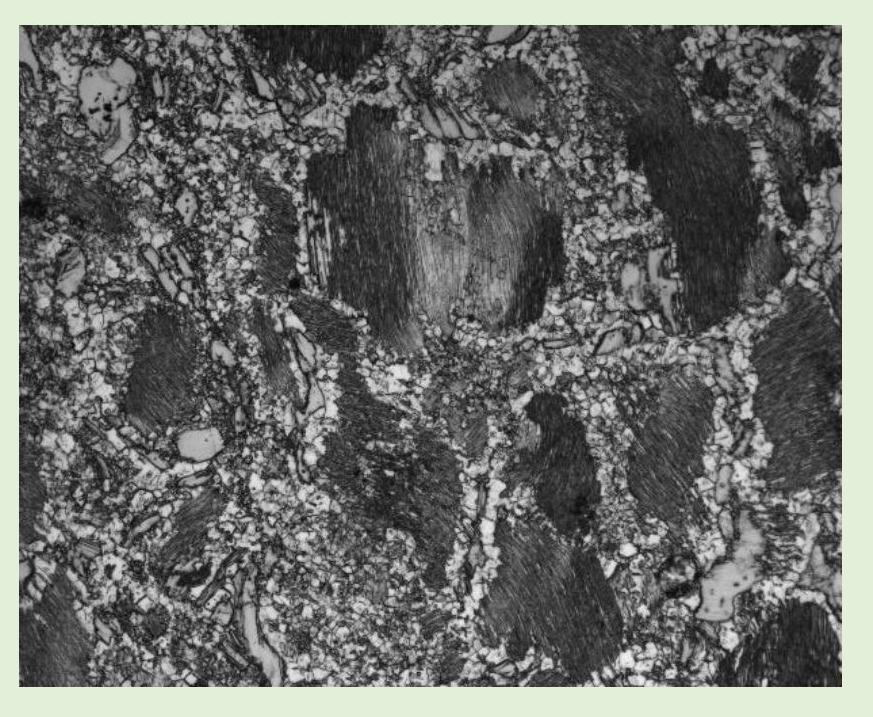

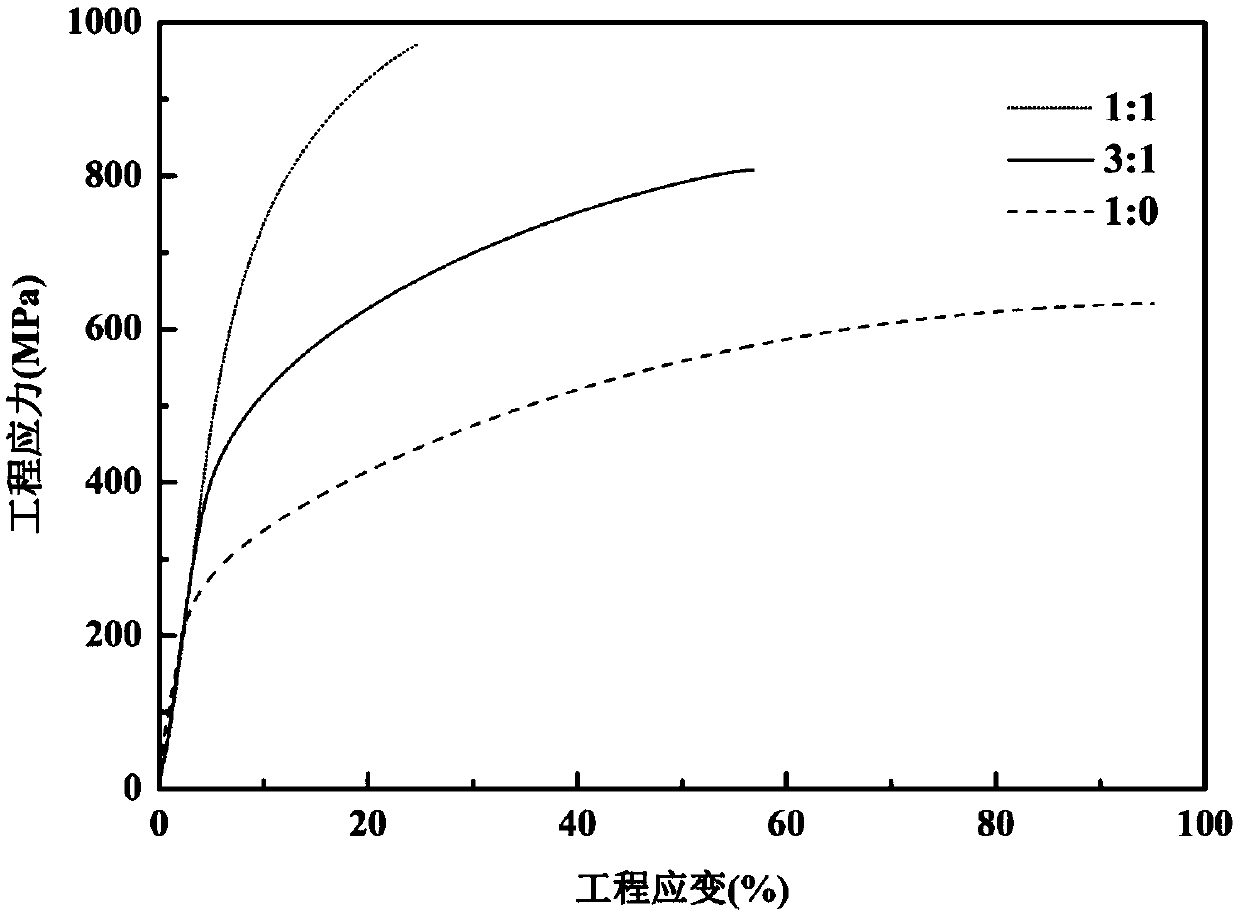

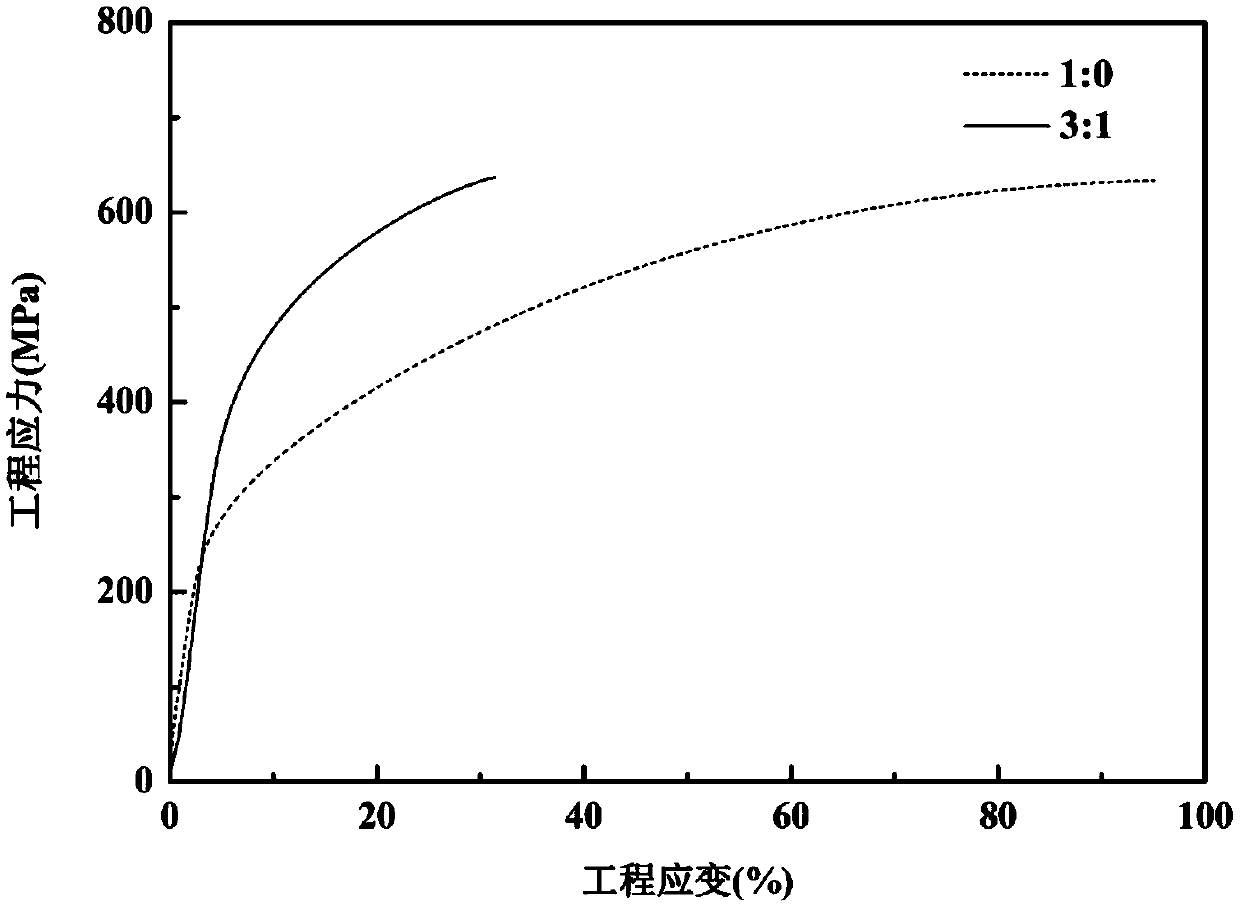

Double-scale structure titanium alloy based on in-situ whisker strengthening and toughening, preparation and application

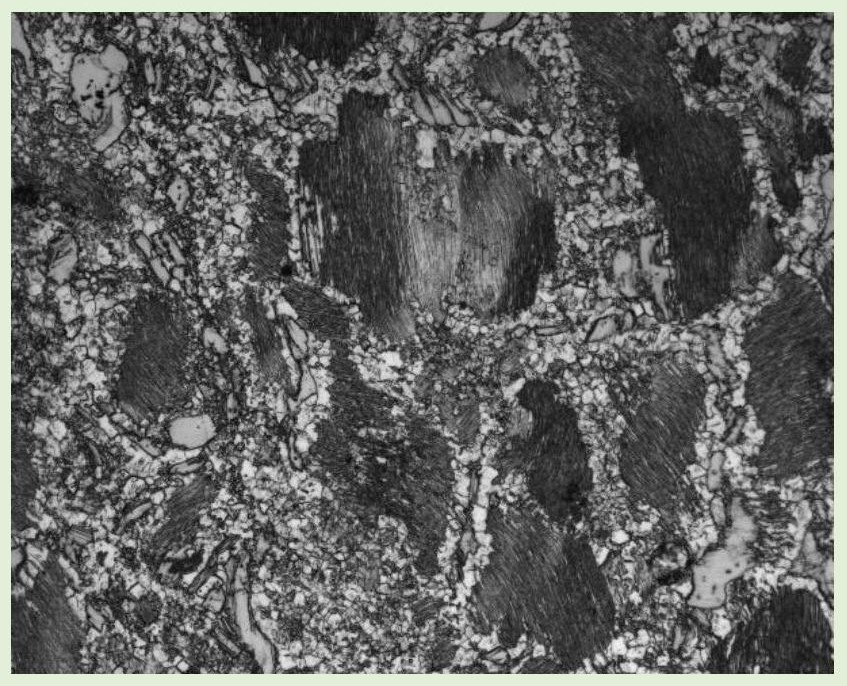

The invention belongs to the field of titanium alloy materials, and discloses a double-scale structure titanium alloy based on in-situ whisker strengthening and toughening and a preparation method and application of the double-scale structure titanium alloy. The titanium alloy comprises elements including, by atomic percent, 58%-70% of Ti, 9%-16% of Nb, 4%-9% of Cu, 4%-9% of Ni, 2%-8% of Al and 0.5%-3% of B. According to a microstructure of the titanium alloy, part of ultra-fine grain fcc MTi2 is distributed along a micron grain bcc beta-Ti base body grain boundary in a long-strip-shaped manner, part of ultra-fine grain fcc MTi2 is distributed in the micron grain bcc beta-Ti in a long-strip-shaped manner, ultra-fine grain in-situ TiB whiskers are distributed in the ultra-fine grain fcc MTi2 and a micron grain bcc beta-Ti of the grain boundary, and M is equal to Cu and Ni. The fine-needle-shaped in-situ TiB whiskers are introduced in a double-scale structure of an ultra-fine grain second phase and a micron equiaxed grain base body, and further strengthening and toughening of the material are achieved.

Owner:SOUTH CHINA UNIV OF TECH

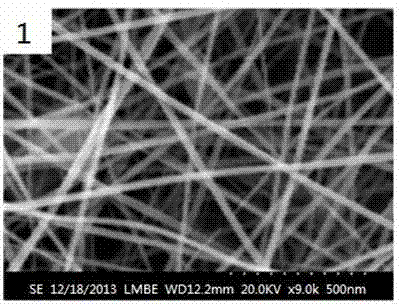

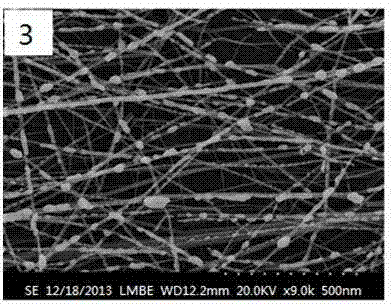

Method for preparing nano fiber composite material containing PMMA (Polymethyl Methacrylate)

ActiveCN103898771AHigh mechanical strengthImprove thermal stabilityFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberSpinning

The invention discloses a method for preparing a nano fiber composite material containing PMMA (Polymethyl Methacrylate). The method comprises the following steps: (1) after drying nano PMMA at 70-90 DEG C and adding the nano PMMA into a solvent; and uniformly agitating under a sealed condition at 60 DEG C and dissolving to obtain a PMMA solution; (2) adding a fluorine-containing high-molecular polymer and agitating at a room temperature for dissolving to obtain a nano PMMA / fluorine-containing high-molecular polymer solution; (3) adding an ethanol solution into nano oxide particles and carrying out ultrasonic vibration; (4) adding a dispersed nano oxide solution into the PMMA / fluorine-containing high-molecular polymer solution to obtain a spinning solution; and (5) uniformly coating at least one face of a structural layer fiber fabric with the spinning solution by an electrostatic spinning technology to form the nano fiber composite material containing the PMMA. According to the method, raw materials are easily available; the obtained nano fiber composite material has high mechanical strength, excellent heat stability, excellent weather resistance, high porosity and good light transmission and ventilation performances, has a function of blocking superfine particles and has very great application and industrialization values.

Owner:符思敏

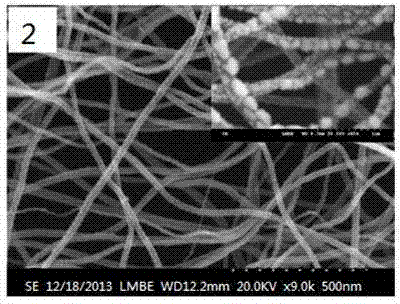

Method for preparing CA (cellulose acetate) nanofiber composite

ActiveCN105316938AHigh porosityImprove light transmission and ventilationFibre treatmentPorosityCellulose acetate

The invention discloses a method for preparing CA (cellulose acetate) nanofiber composite. The method includes the following steps: preparing a CA solution; adding zinc salt and ferric salt; preparing a gelatin solution; adding copper salt and zinc salt; performing double-nozzle electrostatic spinning by adopting the CA solution and gelatin solution as the spinning solution; uniformly coating at least one surface of the structural layer fiber fabric with the spinning solution; then placing the fabric in glutaraldehyde steam for fumigation; carrying out fluoridation so as to obtain the CA nanofiber composite. According to the invention, the raw materials are easy to obtain, firstly, CA and the gelatin are combined, and then through fluorination, so that the nanofiber composite keeps higher mechanical strength, excellent heat stability and weather resistance, in addition, the combination of CA with gelatin achieves higher porosity as well as good light transmission and ventilation, so that the composite is good in affinity with the human body, is environment-friendly, can efficiently obstruct ultrafine particles, and has great application and industrialization value.

Owner:YANGZHOU NABAICHENG NANO TECH CO LTD

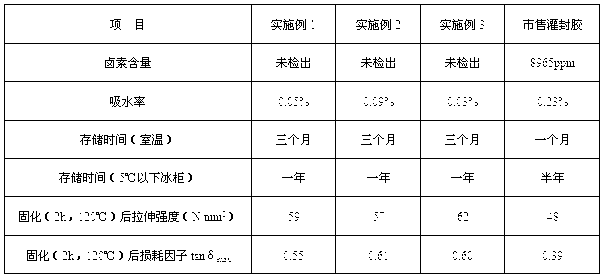

High-damping halogen-free pouring sealant and preparation method thereof

InactiveCN103173172AIncrease lossImprove damping performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceHalogen

The invention relates to high-damping halogen-free pouring sealant and a preparation method thereof. The high-damping halogen-free pouring sealant is obtained by the following method comprising the following steps of: uniformly mixing diluents, filler, foam magnesium damping agent, plasticizer, coupling agent, pigment and epoxy resin in proportion to obtain a component A; and uniformly mixing the component A with curing agent in proportion to obtain the high-damping halogen-free pouring sealant. According to the high-damping halogen-free pouring sealant and the preparation method thereof disclosed by the invention, the pouring sealant, which is prepared by using foam magnesium as damping agent and adopting the halogen-free material, has a higher loss factor and damping performance, good damping and noise-reducing performances and small moisture adsorption; moreover, high-damping halogen-free pouring sealant satisfies the halogen-free equipments and is larger in industrial practical value.

Owner:东莞市松山湖微电子材料研发中心

Lithographic Printing Plate Precursor

InactiveUS20090110887A1Great industrial valueExcellent performancePhotosensitive materialsLayered productsWater soluble polymersWater soluble

An object of the present invention is to provide a lithographic printing plate precursor which is less apt to suffer from contamination by ablation in forming an image and having an excellent printing performance through image formation. A lithographic printing plate precursor comprises a base material (I), a photosensitive layer (II) containing a light / heat conversion agent on the base material (I), and a layer (III) covering the photosensitive layer (II), wherein the layer (III) covering the photosensitive layer contains both a water-soluble polymer and a hydrophobic polymer, and contains substantially no light / heat conversion agent is provided. The layer (III) covering the photosensitive layer is preferred to contain the water-soluble polymer and the hydrophobic polymer in a proportion of from 10:90 to 90:10 by mass.

Owner:MITSUI CHEM INC

Manufacturing method for silicon thin-film solar cell

InactiveCN101364619AImprove photoelectric conversion efficiencyLow costFinal product manufactureSemiconductor devicesElectrode interfacePolycrystalline silicon

The invention discloses a method for manufacturing a thin silicon film solar battery. The method comprises the following steps: P-type high-purity polysilicon with the purity of more than 99.999% is firstly crushed into high-purity polysilicon powder with the granularity of 5-50 micron; the polysilicon powder is applied on a substrate combined with an aluminum electrode to form a high-purity p-type silicon micron granular film; silicon micron granules and a metal conductive bottom electrode interface are alloyed through the anneal technology; then an n-type silicon layer is deposited on the silicon granular single-layer film, or an intrinsic silicon layer and the n-type silicon layer are deposited in sequence; and finally a transparent conductive electrode layer is deposited. The method adopts the unique technology of crushing and applying high-purity polysilicon raw material to realize the deposition of the high-quality polysilicon film on substrates such as glass, plastics, metal sheets, etc., and the technological method for manufacturing the solar battery has the advantages of simplicity, low manufacture cost, high efficiency of photoelectric conversion and broad value of industrialization.

Owner:HUNAN UNIV

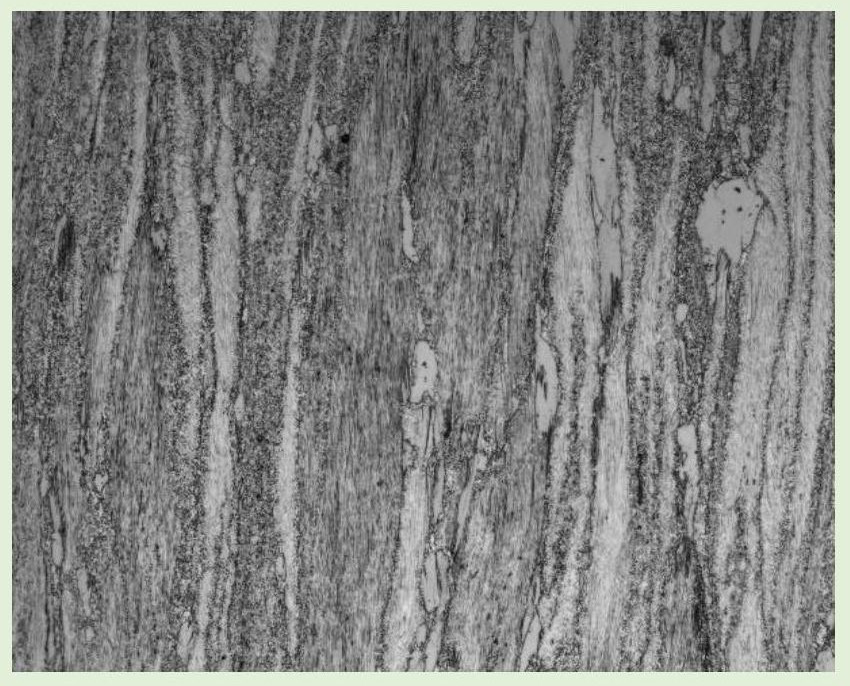

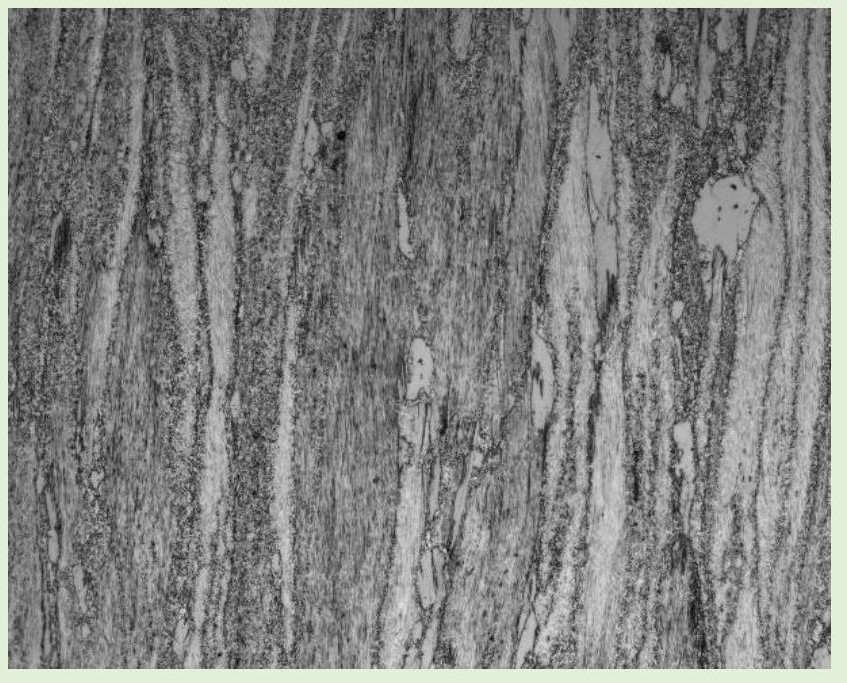

Rare earth magnesium alloy with high strength and toughness and treatment method thereof

The invention relates to a rare earth magnesium alloy with high strength and toughness and a treatment method thereof. The rare earth magnesium alloy is Mg-(7-12) Gd-(3-6) Y-(1-3) Zn-(0.2-1) Zr (wt.%), the rare earth magnesium alloy comprises uniform and fine grains with the average grain size not larger than 35 microns, and dense short-rod-shaped LPSO phases and cylindrical beta' nanometer strengthening phases which are precipitated from the uniform and fine grains; and the treatment method comprises the steps of deformation rare earth magnesium alloy with a double-peak microstructure, primary aging, annealing and secondary aging. According to the method, through the method that alternate aging and annealing treatment are carried out on the rare earth magnesium alloy, a fine grain structure with the short-rod-shaped long-range ordered phases and beta' strengthening phases which are uniformly and densely distributed is obtained, crack initiation can be inhibited, the mechanical performance of the alloy can be improved, and finally the rare earth magnesium alloy with high strength and toughness is prepared.

Owner:ZHONGBEI UNIV

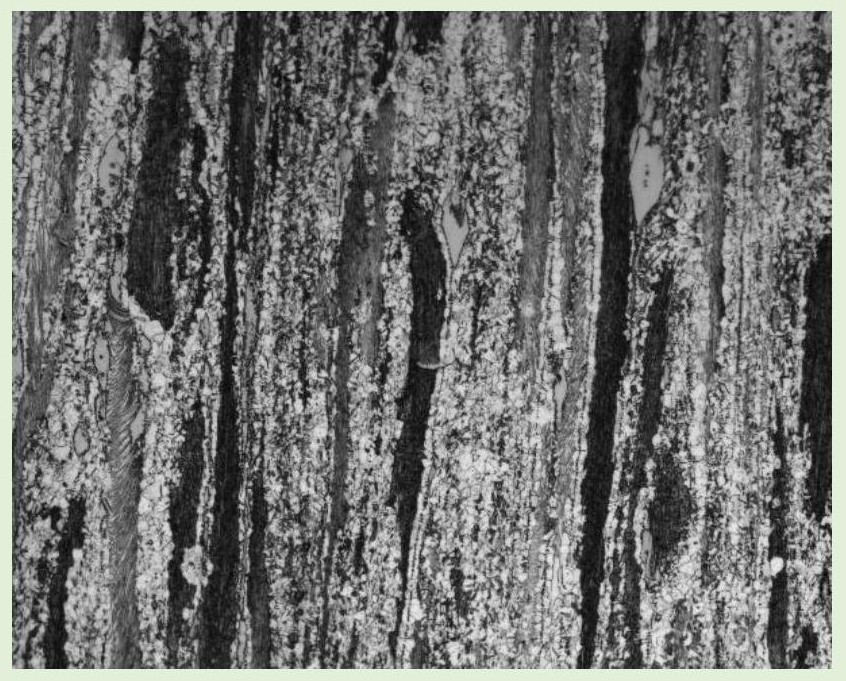

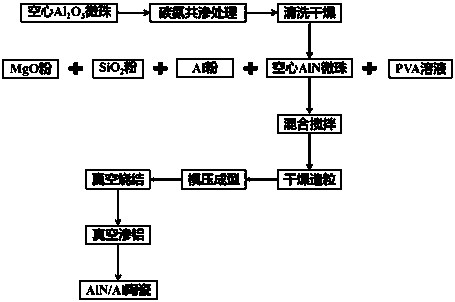

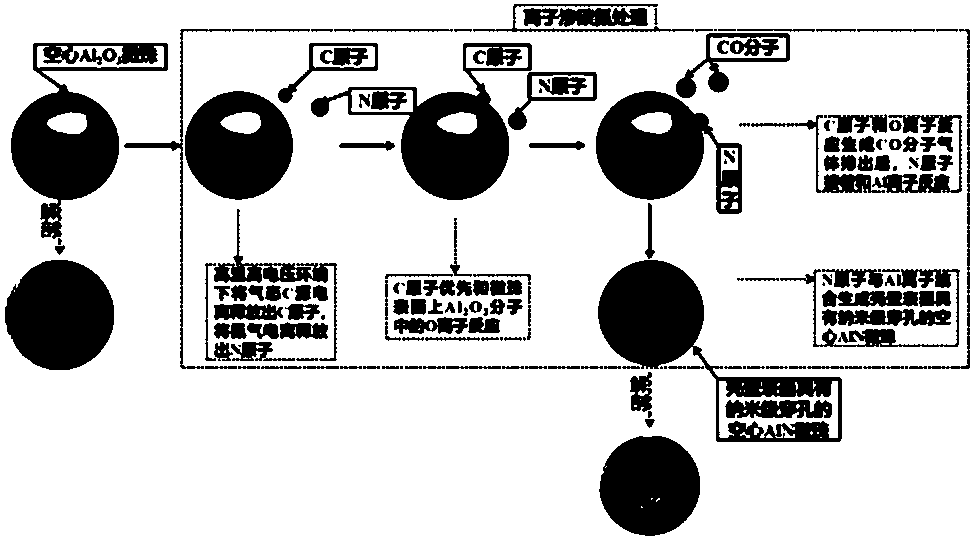

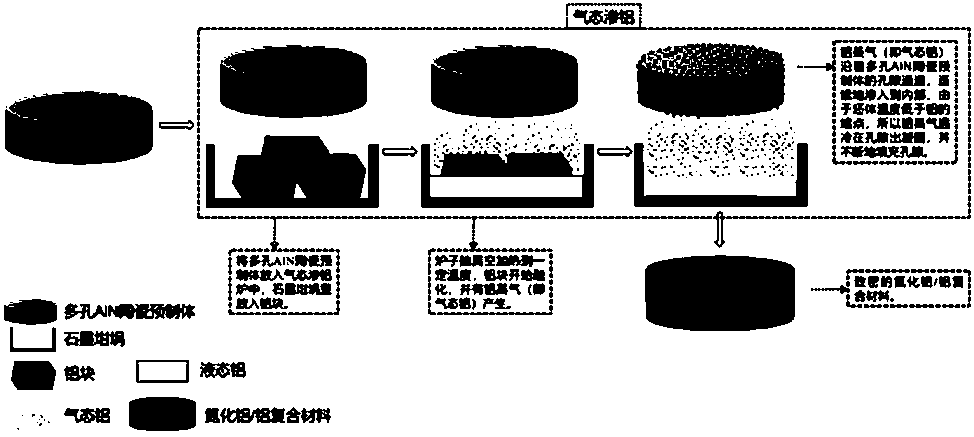

Preparation method of aluminum nitride-aluminum composite material

InactiveCN110950665ADoes not damage the macroscopic hollow structureLight in massCeramicwareThermal transmittanceHeat treated

The invention relates to a preparation method of an aluminum nitride-aluminum composite material, and belongs to the field of electronic packaging materials, wherein the method comprises: ion carbonitriding treatment, cleaning, mixing, sintering and gaseous aluminizing. According to the method, hollow aluminum oxide micro-beads are changed into hollow aluminum nitride micro-beads with nano-scale perforations in the shell wall by adopting an ion carbonitriding process, wherein the temperature of the vacuum ion carbonitriding heat treatment is 1200 to 1450 DEG C, the heating rate is 5-20 DEG C / min, and the heat preservation time is 30-60 min; a porous aluminum nitride billet is obtained without adding of pore forming agents and foaming agents; and an aluminum nitride-aluminum composite material with high density, high thermal conductivity and high comprehensive mechanical strength is obtained through a gaseous aluminizing process. According to the invention, the composite material is widely applied to high-temperature heat dissipation elements, high-power microwave integrated circuits, power electronic devices, high-power laser or LED lighting electronic packaging.

Owner:山东东大新材料研究院有限公司 +1

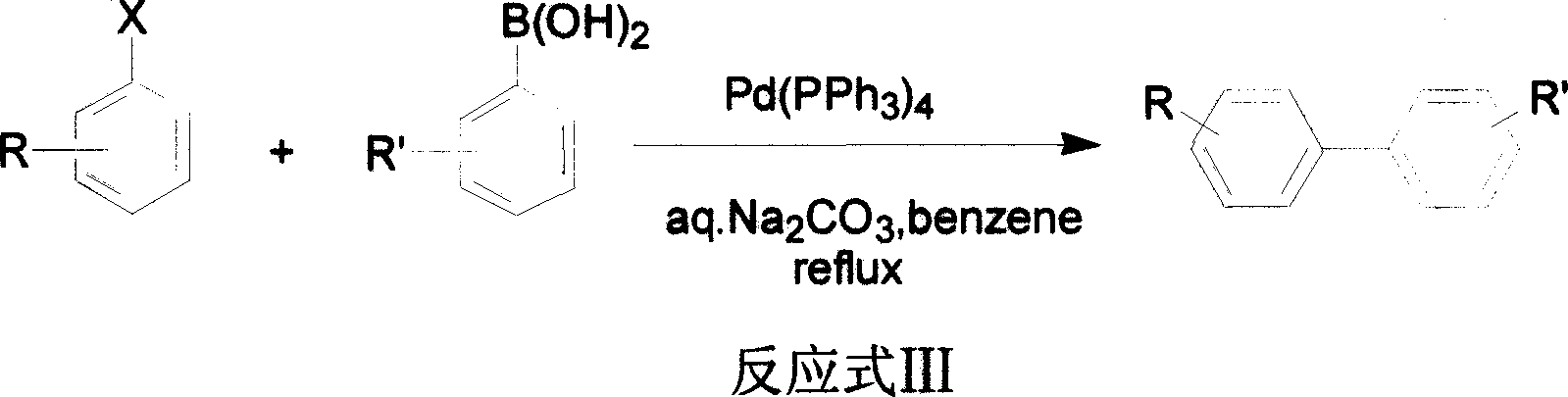

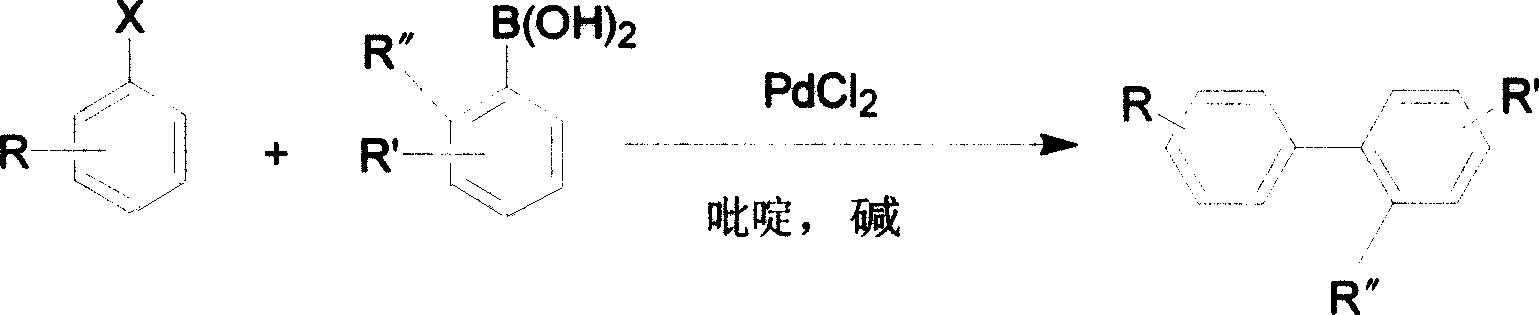

Method for cross coupling reaction utilizing substituted halogenated arene and substituted aryl boric acid

InactiveCN1935754ASimple methodLow costCarboxylic acid nitrile preparationOrganic compound preparationArylBoric acid

The invention relates to a method of making cross-coupling reaction using substituted and halogenated aromatic hydrocarbons and substituted aryl boracic acid, making them perform cross-coupling reaction by the action of palladium chloride catalyst in pyridine solvent at return flow temperature on alkali condition of potassium carbonate or potassium phosphate. And it is simple to operate and low-cost, the solvent is easy to get and able to recycle, the reaction activity is high, the purity of product is higher than 99.5%, the yield of product is up to 60-90%, and it has extreme industrial practical value.

Owner:EAST CHINA UNIV OF SCI & TECH +1

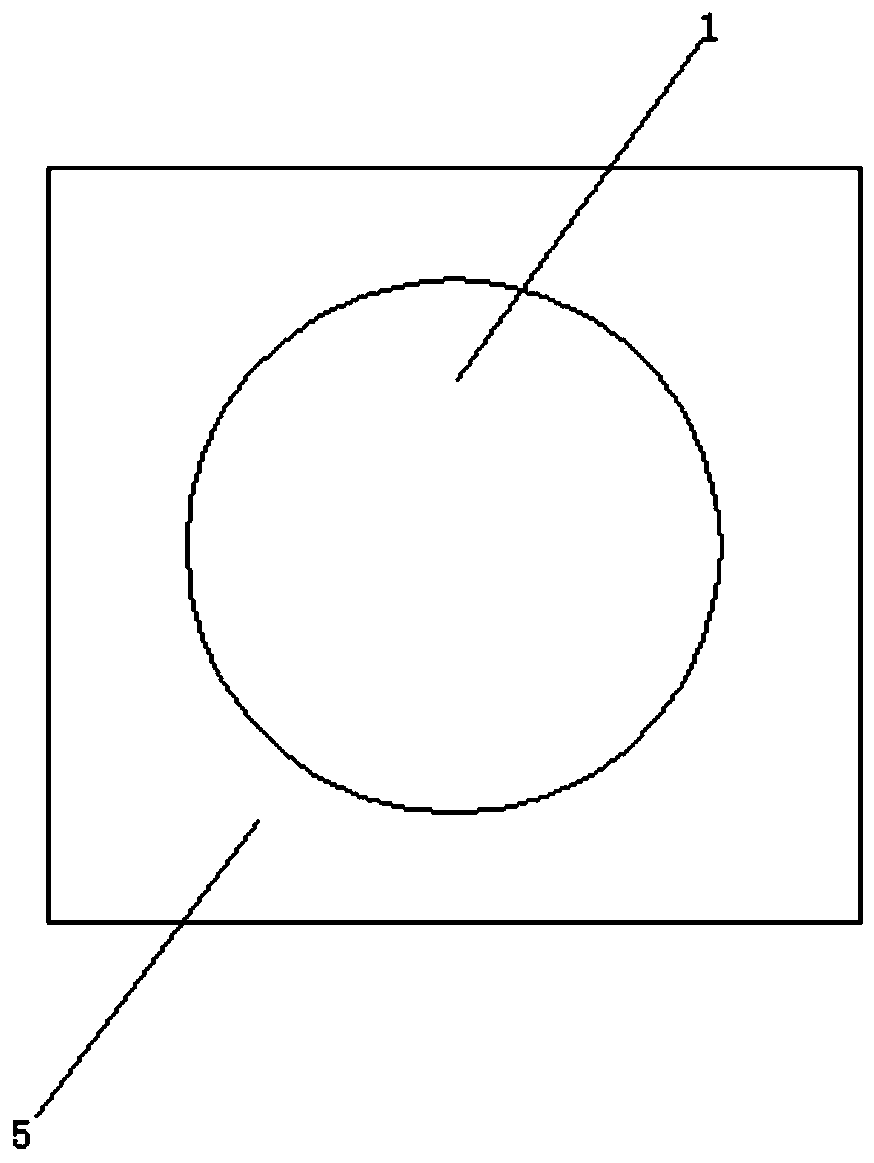

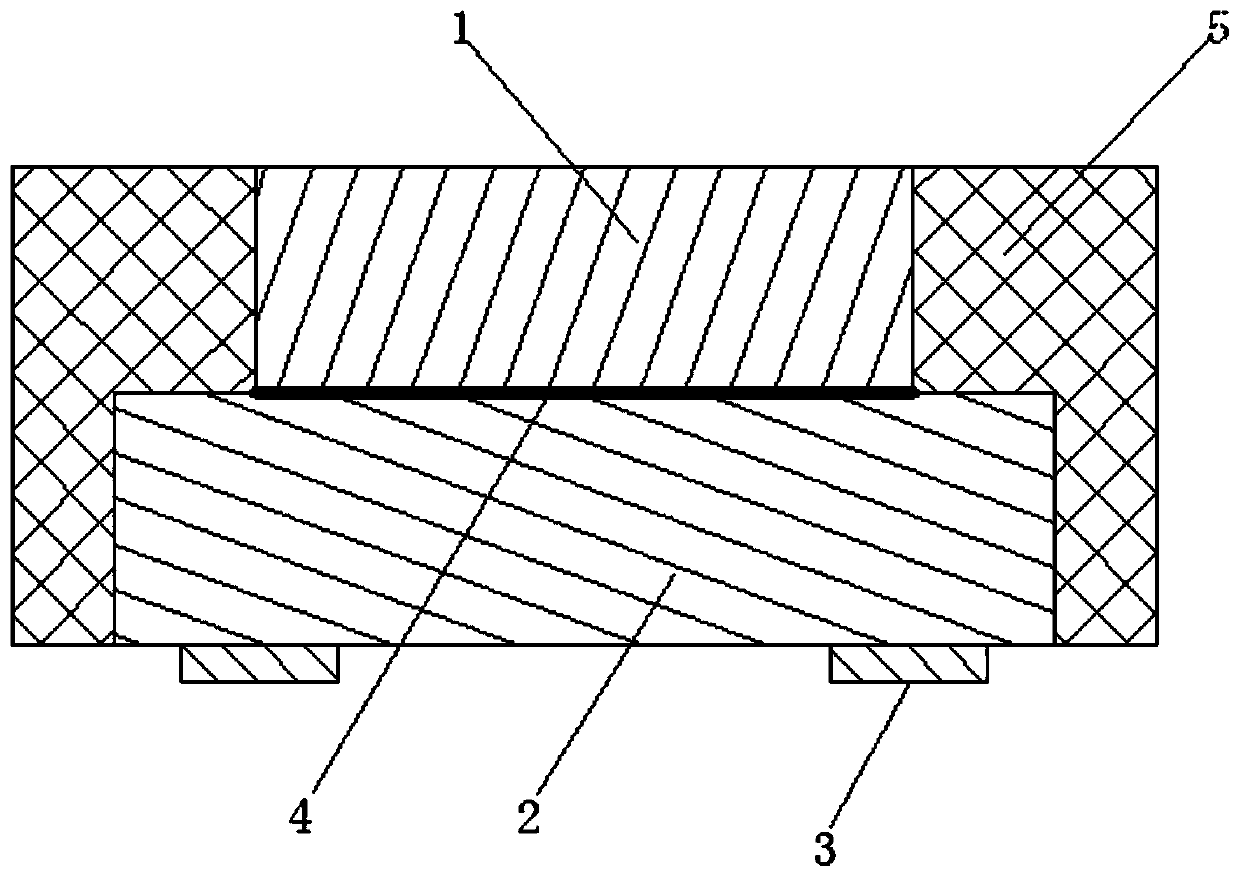

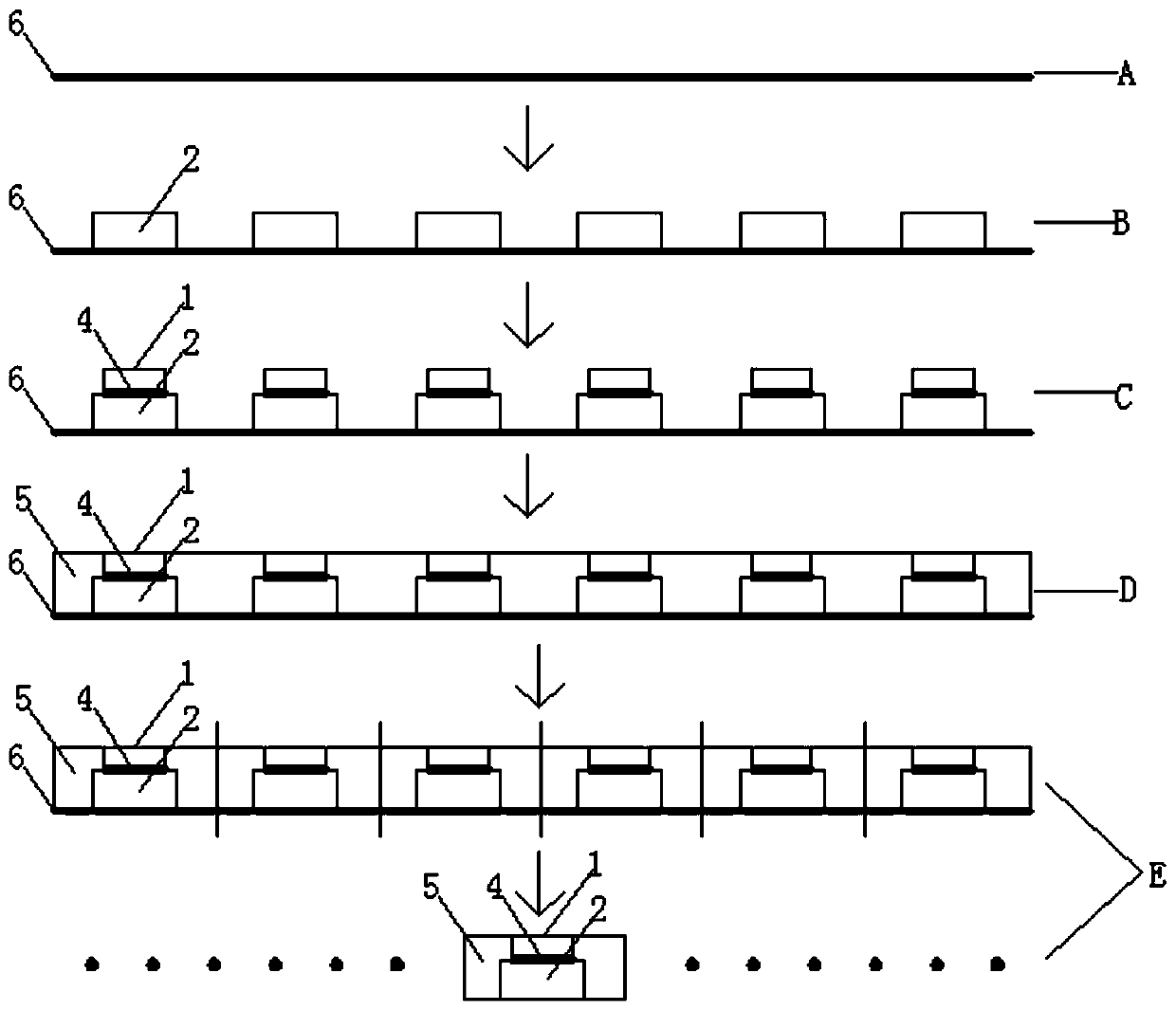

CSP LED with round light-emitting surface and processing method of CSP LED

PendingCN110350068AImprove visual effectsGood light distributionSemiconductor devicesState of artFluorescence

The invention discloses a CSP LED with a round light-emitting surface and a processing method of the CSP LED. An LED chip is positioned by a carrier film, and single fluorescent films are placed on the LED chip and are pasted and fixed one by one. Different from a package process of a CSP LED having a square and downwards-facing light-emitting surface in the prior art, mass and automation mass ofthe CSP LED with the round light-emitting surface is achieved by a package method allowing the light-emitting surface to face upwards; compared with the CSP LED with the square light-emitting surface,the CSP LED with the round light-emitting surface is good in visual effect, and grading is convenient; the technical blank of the CSP LED with the round light-emitting surface is filled up, the product is good in optical effect, wide in application range, novel and unique in processing method, high in production efficiency and high in yield and has great industrial value and economic value, and the CSP LED with the round light-emitting surface is suitable for the CSP LED and the package process thereof.

Owner:昆山芯乐光光电科技有限公司

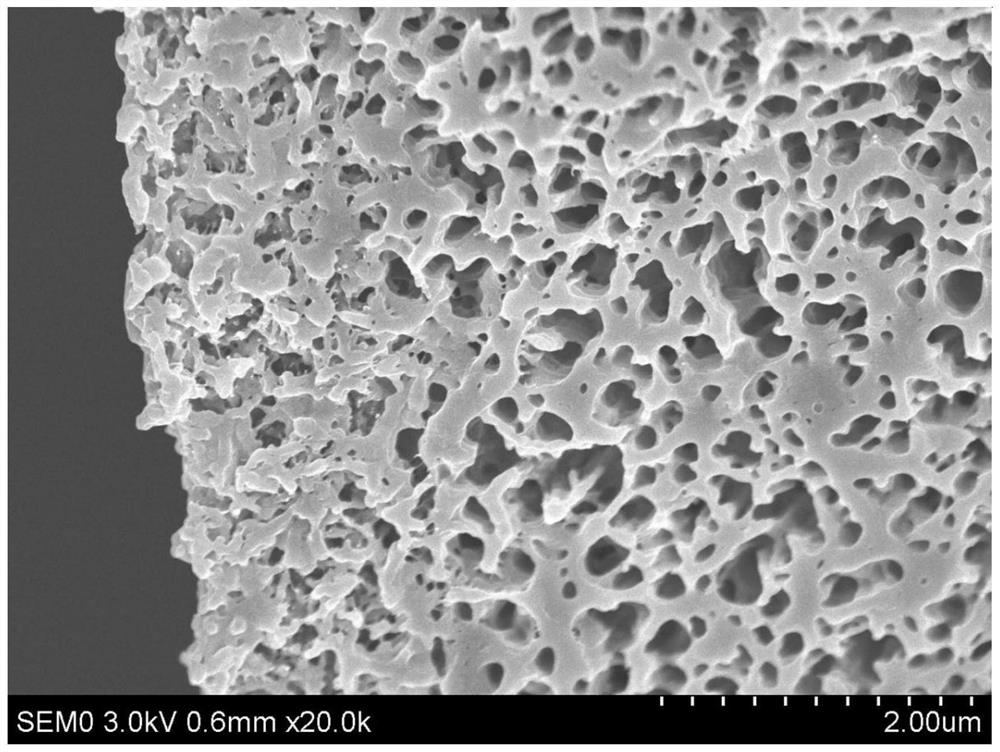

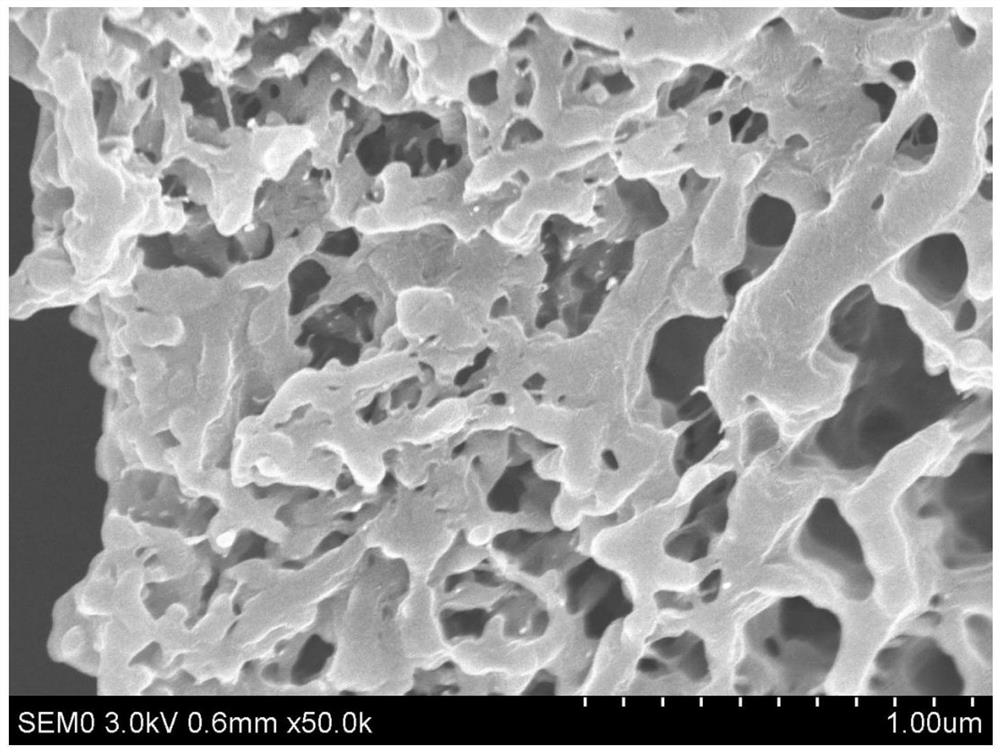

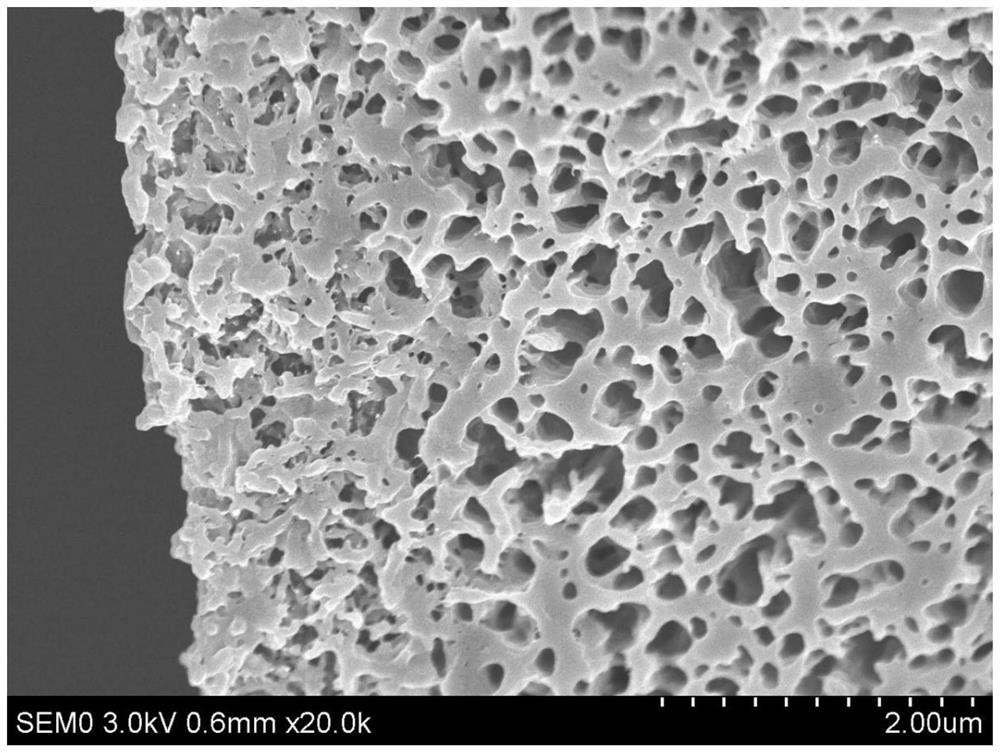

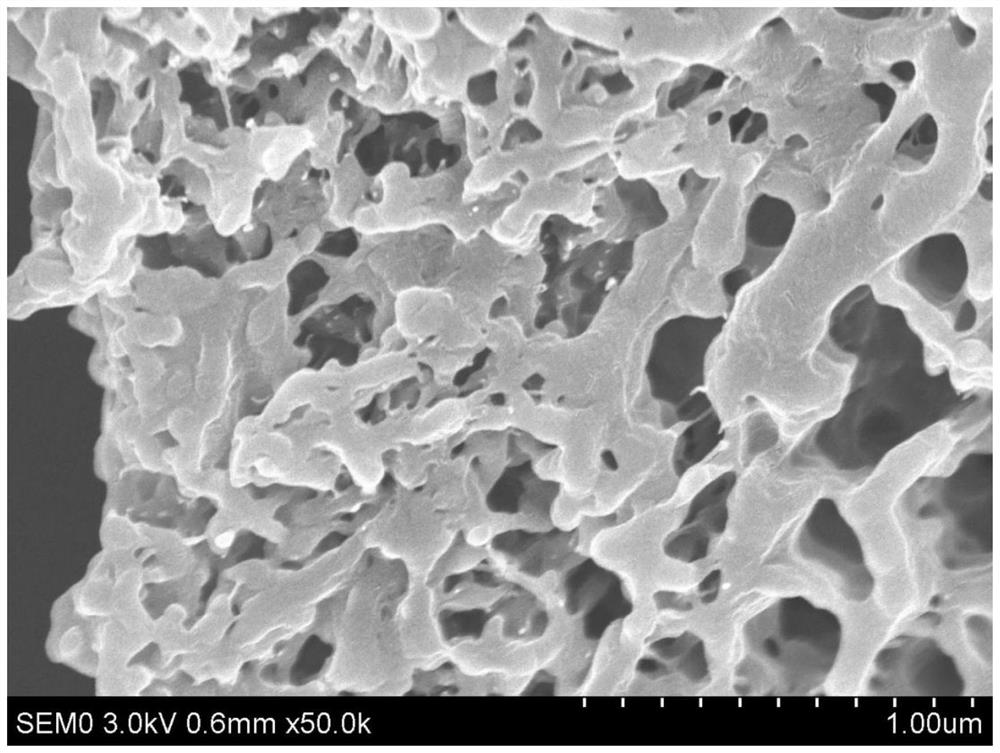

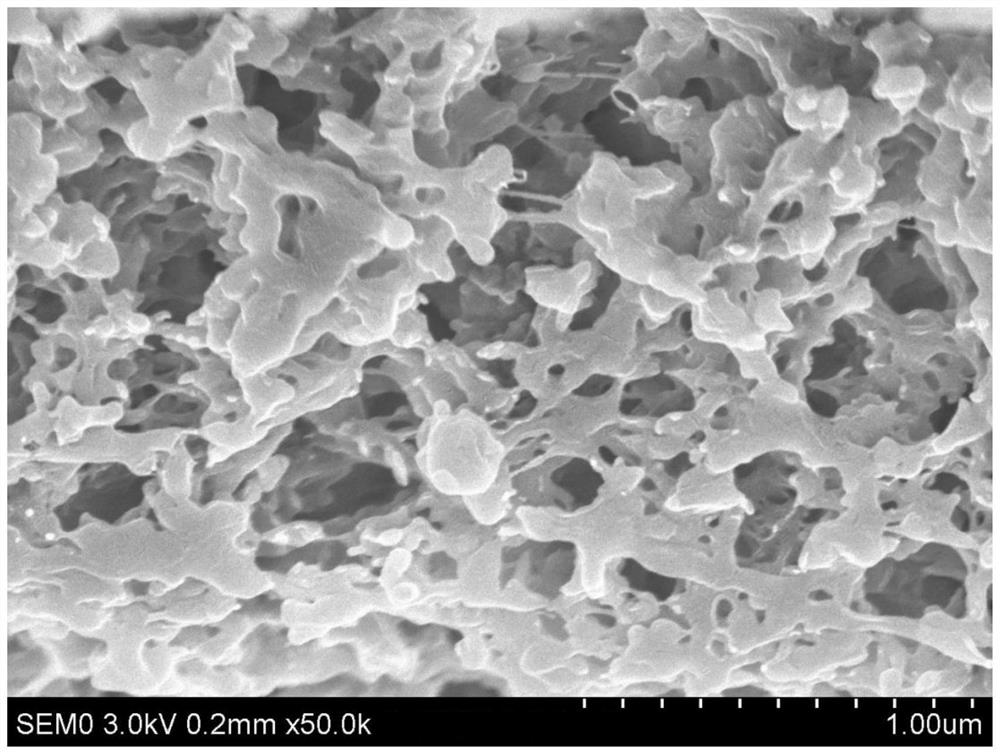

Preparation method of asymmetric hollow fiber membrane

PendingCN114733366AHigh mechanical strengthGreat industrial valueMembranesSemi-permeable membranesPhysical chemistryHollow fiber membrane

The invention provides a preparation method of an asymmetric hollow fiber membrane, which comprises the following steps: preparing a membrane casting solution, and extruding the membrane casting solution into a molded product through a die head, performing split-phase curing on the molded product, and performing quenching treatment to obtain a green film; then extracting a solvent system in the green film by using an extracting solution at the extraction temperature of 40-80 DEG C and the concentration of the extracting solution in the extraction process is not lower than 90%, so that the solvent system can be removed from the green film only by 1-4 hours; performing low-temperature drying and high-temperature shaping on the original membrane to obtain a hollow fiber membrane; according to the method, in the process of preparing the hollow fiber membrane, the extraction time can be shortened, and the extraction quality can be ensured, so that a solvent system can be completely removed from membrane filaments by the extract liquor within a relatively short time, and the economic benefit is ensured; meanwhile, it can be guaranteed that the finally prepared hollow fiber membrane has long plasma permeation time, and the plasma permeation time is at least 48 h; and the membrane also has high gas mass transfer rate and large mechanical properties, and is especially suitable for being used as a blood oxygenation membrane.

Owner:杭州费尔新材料有限公司

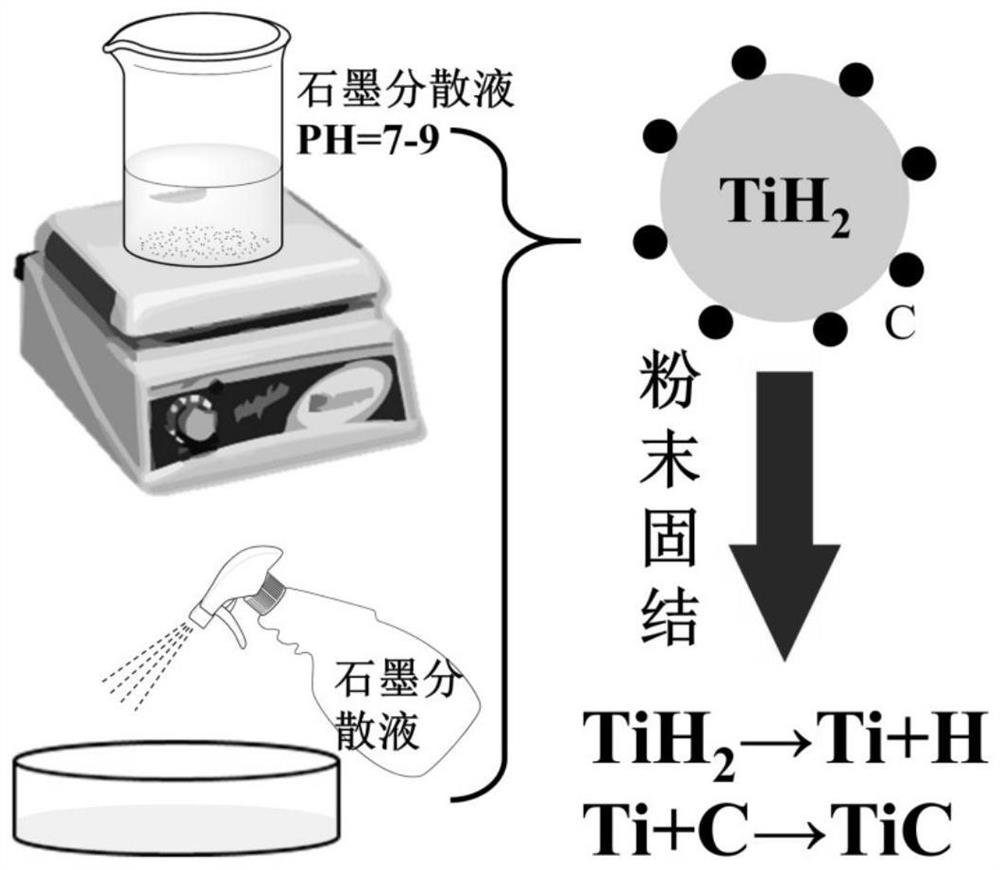

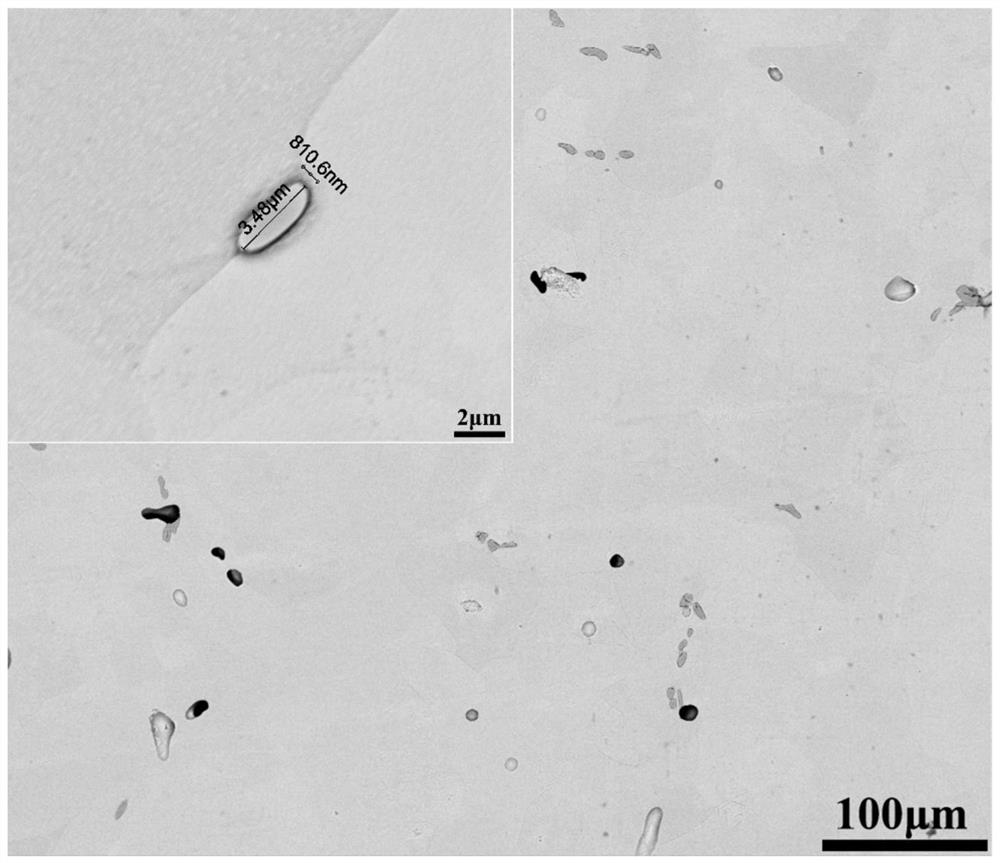

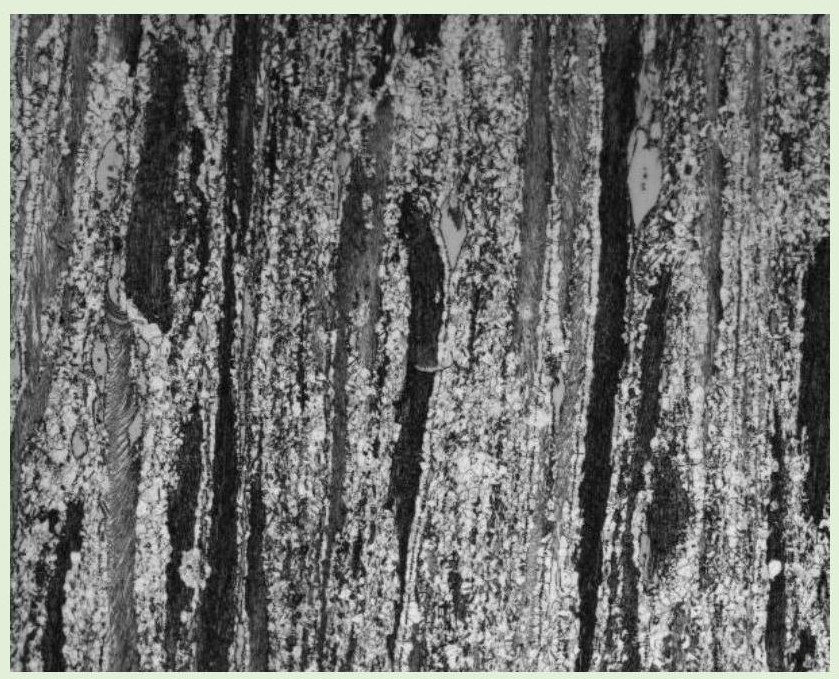

Method for preparing titanium-based composite material by sintering pre-dispersed graphite composite titanium hydride

ActiveCN112281009ASolve reunionSolve problems such as poor alloy performanceTitanium matrix compositesNonferrous metal

The invention belongs to the technical field of nonferrous metal processing, and discloses a method for preparing a titanium-based composite material by sintering pre-dispersed graphite composite titanium hydride and the prepared composite material. Specifically, titanium hydride powder and graphite powder are used as raw materials to form a TiC reinforced titanium-based composite material by powder metallurgy. The method comprises the following steps that firstly, the graphite powder is pre-dispersed by using polyvinylpyrrolidone; and then, the graphite powder is attached on the surface of titanium hydride for sintering formation, so that such problems as powder agglomeration and weak alloy performance caused by direct physical mixing of the titanium hydride and the graphite powder are solved. The tensile strength of the obtained TiC reinforced titanium-based composite material can be 535 MPa; the elongation after fracture can be 10%; the optimized wear volume is reduced by 15% compared with pure titanium; compared with a titanium-based composite material prepared by using titanium hydride as a raw material reported in the literature, the breakthrough in greatly improving the tensile plasticity is realized; and the method can be applied to the preparation of high-strength parts or wear-resistant structural parts in the fields of aerospace, armored cars, weapons, ships and automobiles.

Owner:SOUTH CHINA UNIV OF TECH +1

Chromium-free pre-passivating liquid for hot-galvanized steel pipes

ActiveCN111575693AImprove high temperature stabilityImprove corrosion resistanceHot-dipping/immersion processesChromium freeHazardous substance

The invention belongs to the technical field of metal surface treatment and corrosion protection, and particularly relates to chromium-free pre-passivating liquid for hot-galvanized steel pipes. The chromium-free pre-passivating liquid is prepared from following components in percent by weight: 5%-10% of a film forming agent, 2%-4% of an oxidizing agent, 2%-4% of an organic corrosion inhibitor, 2%-4% of an inorganic rare earth corrosion inhibitor, 0.5%-2% of a water quality stabilizer, 0.5%-2% of a base material wetting agent and the balance water. A preparation method of the chromium-free pre-passivating liquid includes the steps that the film forming agent, the oxidizing agent, the inorganic rare earth corrosion inhibitor and the water quality stabilizer are dissolved in the water, the materials are stirred, then the organic corrosion inhibitor and the base material wetting agent are added, and the materials are evenly stirred. The chromium-free pre-passivating liquid does not contain chromium and other toxic and harmful substances, the high-temperature stability of tank liquor of the chromium-free pre-passivating liquid is good, the appearances of the pre-passivated hot-galvanized steel pipes are bright, the inner walls of the pre-passivated hot-galvanized steel pipes are well resistant to white rust, and the chromium-free pre-passivating liquid can replace chromic anhydridefor pre-passivating.

Owner:WUHAN DESYTEK ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

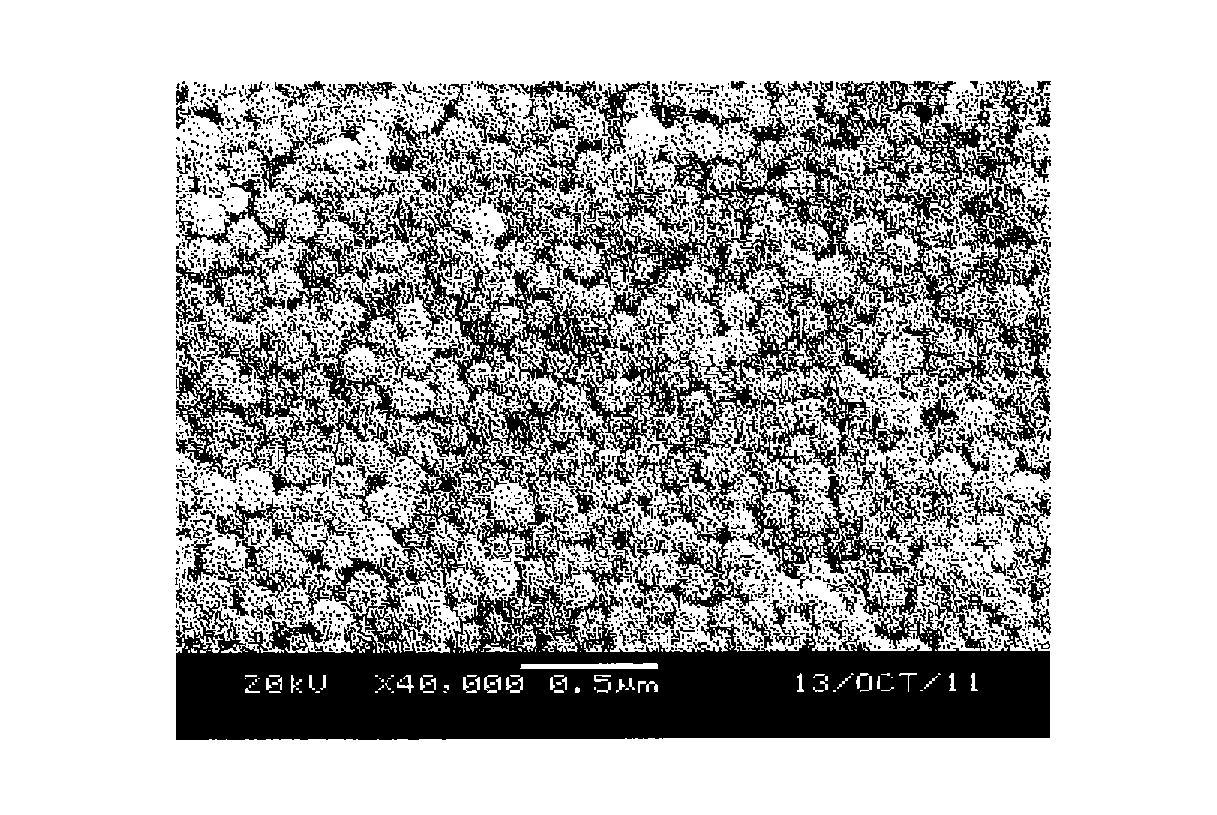

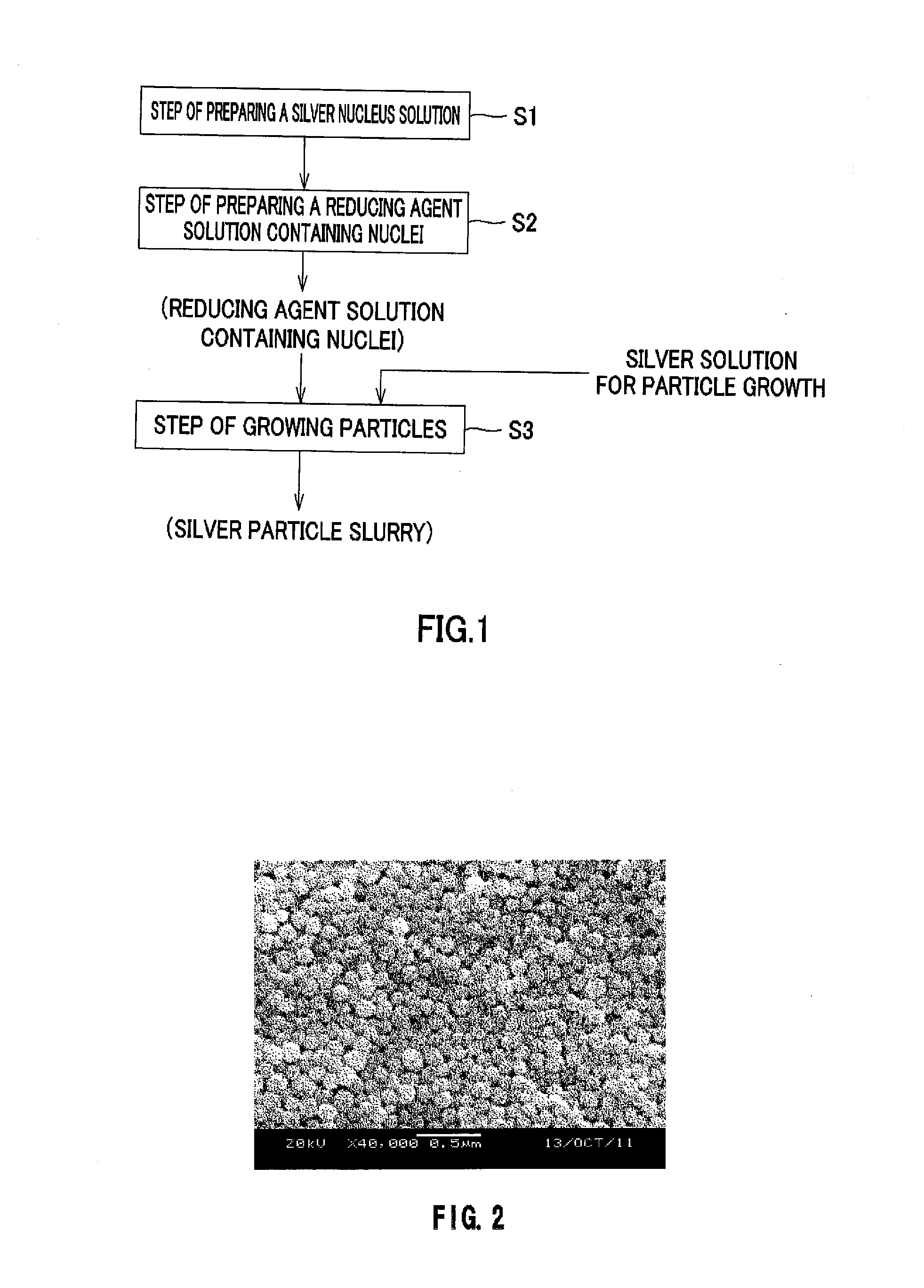

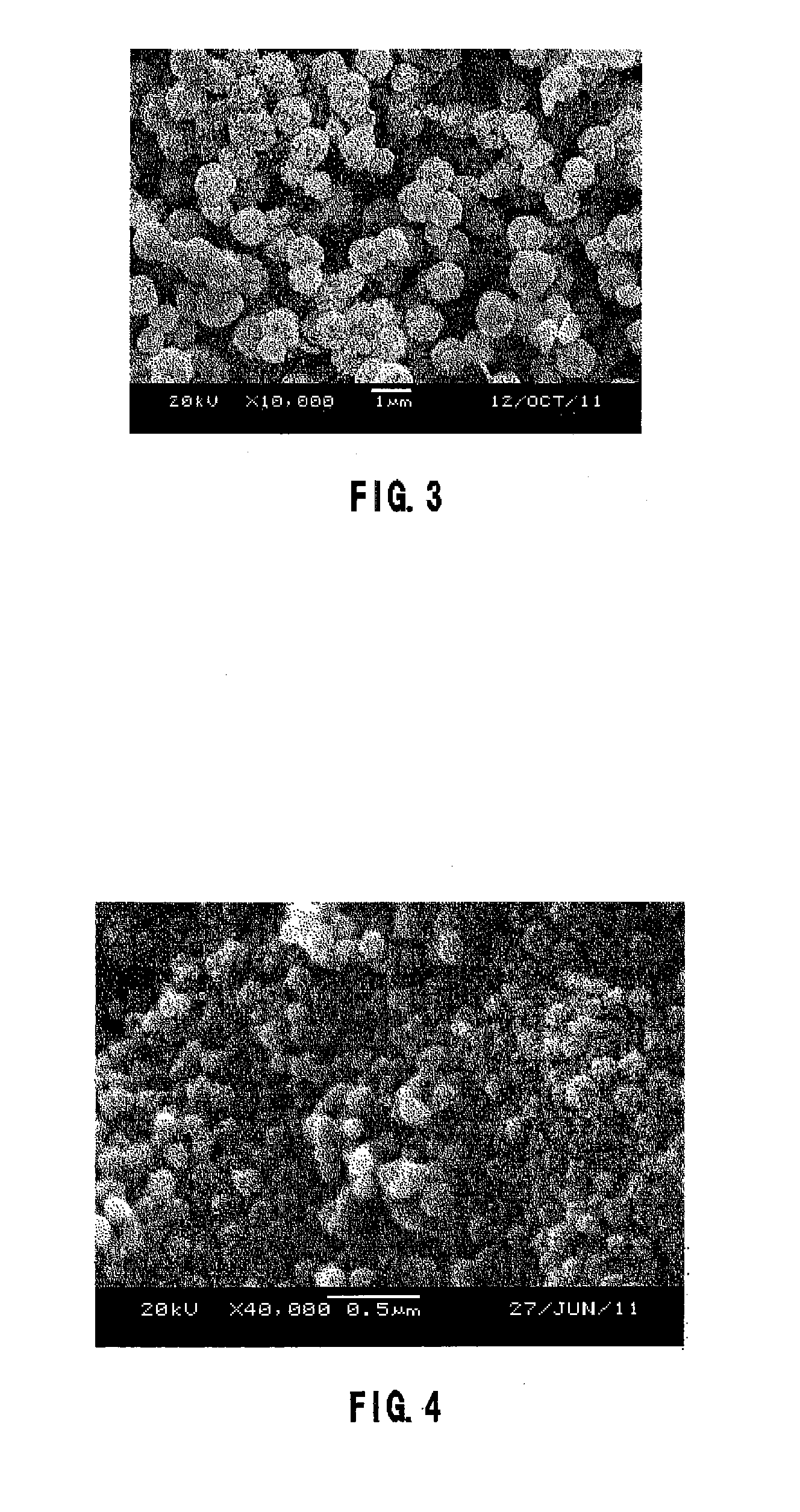

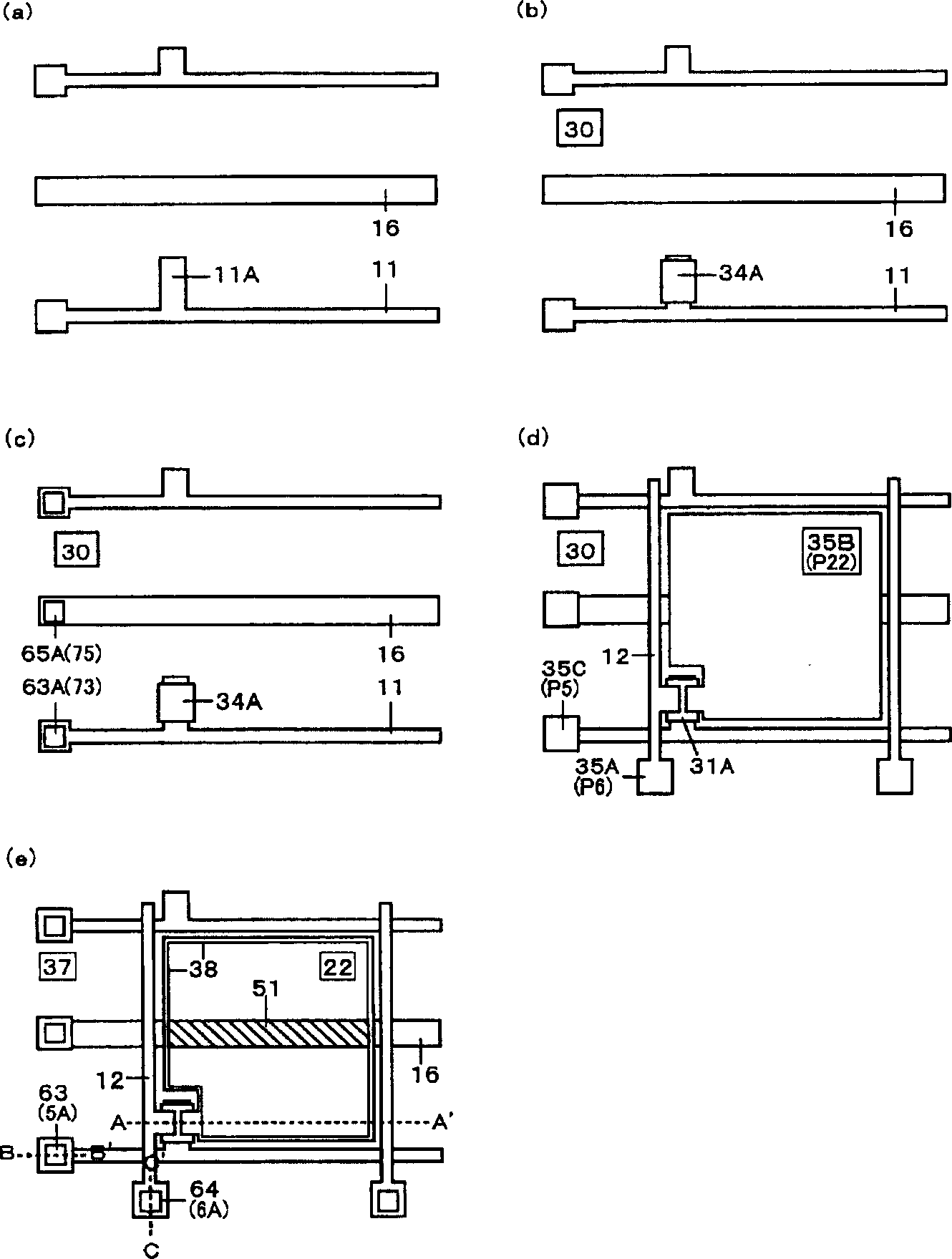

Silver powder and method for producing same

InactiveUS20150099136A1Excellent mass productivityGreat industrial valueMetal-working apparatusThin material handlingSilver particlesMaterials science

A method for producing silver powder wherein a silver solution containing a silver complex and a reductant solution are continuously mixed to provide a reaction liquid, the method including: a step of preparing a silver nucleus solution wherein a silver solution for nucleation which contains a silver complex, a solution containing a strong reductant, and a dispersant are mixed to provide the silver nucleus solution; a step of preparing a reductant solution containing nuclei wherein the silver nucleus solution obtained and a weak reductant having a standard electrode potential higher than that of the strong reductant are mixed to obtain the reductant solution containing nuclei; and a step of growing particles wherein the reductant solution containing nuclei and a silver solution for particle growth containing a silver complex are continuously mixed to provide a reaction solution, in which the silver complex is reduced to thereby grow silver particles.

Owner:SUMITOMO METAL MINING CO LTD

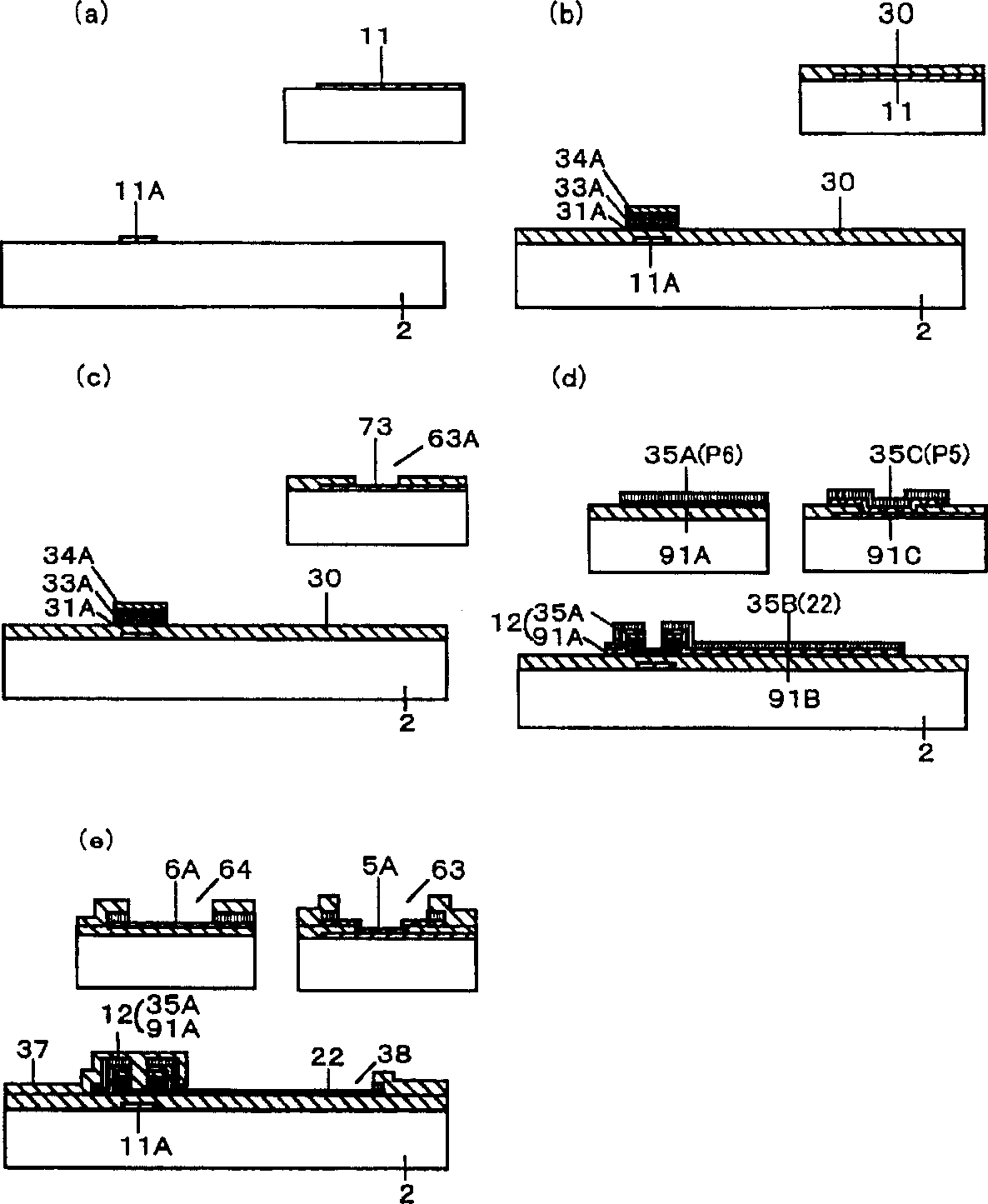

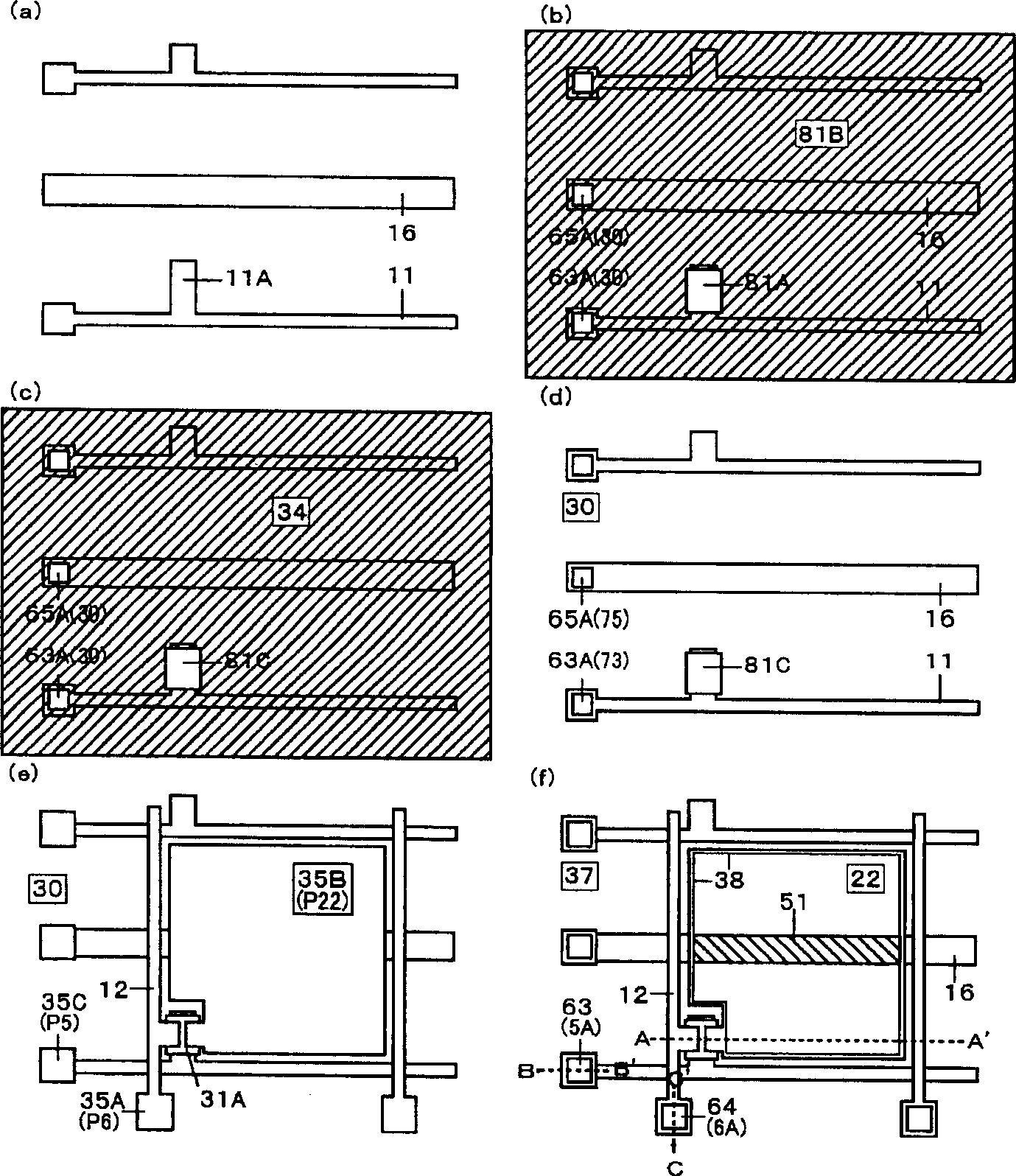

LCD disply device and manufacture thereof

ActiveCN1854871AEnsure electrical connectionLow costTransistorStatic indicating devicesLiquid-crystal displayInsulation layer

A method for preparing liquid crystal display device includes utilizing semitone image exposure technique to semiconductor layer of insulation grid film transistor and source / drain electrode wiring on primary photo-etching process, setting signal wire and analog pixel electrode in stacked mode between transparent conduction layer and low resistance metal, removing off low resistance metal layer on said pixel electrode to obtain pixel electrode formed by transparent conduction layer when opening is formed on passivated insulation layer, removing off grid insulation layer to obtain contact point properly when semiconductor layer is formed.

Owner:QUANTA DISPLAY JAPAN +1

A kind of high strength and toughness rare earth magnesium alloy and its processing method

ActiveCN113444946BEliminate performance differencesConditions that affect plasticity and other performance degradationMagnesium alloyCrystallite

The invention relates to a high-strength and tough rare earth magnesium alloy and a processing method thereof, wherein the rare earth magnesium alloy is Mg-(7-12)Gd-(3-6)Y-(1-3)Zn-(0.2-1)Zr (wt.%), which contains uniform fine grains with an average grain size not greater than 35 μm and dense short rod-shaped LPSO phases and columnar β' nano-reinforced phases precipitated from the uniform fine grains; the treatment method includes Deformed rare earth magnesium alloy with bimodal microstructure, first aging, annealing and second aging. The invention obtains a fine-grained structure with evenly distributed and densely distributed short rod-shaped long-range ordered phases and β'-strengthened phases by means of alternate aging and annealing treatments for rare-earth magnesium alloys, which can suppress the initiation of cracks and improve the mechanical properties of the alloy. performance, and finally prepared a rare earth magnesium alloy with high strength and toughness.

Owner:ZHONGBEI UNIV

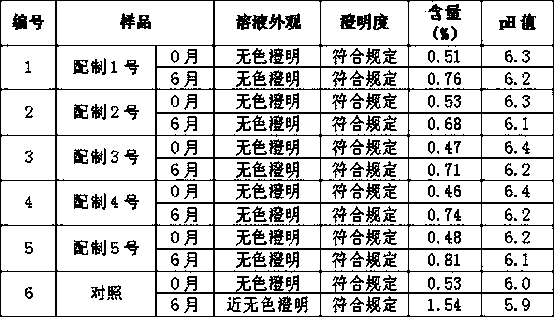

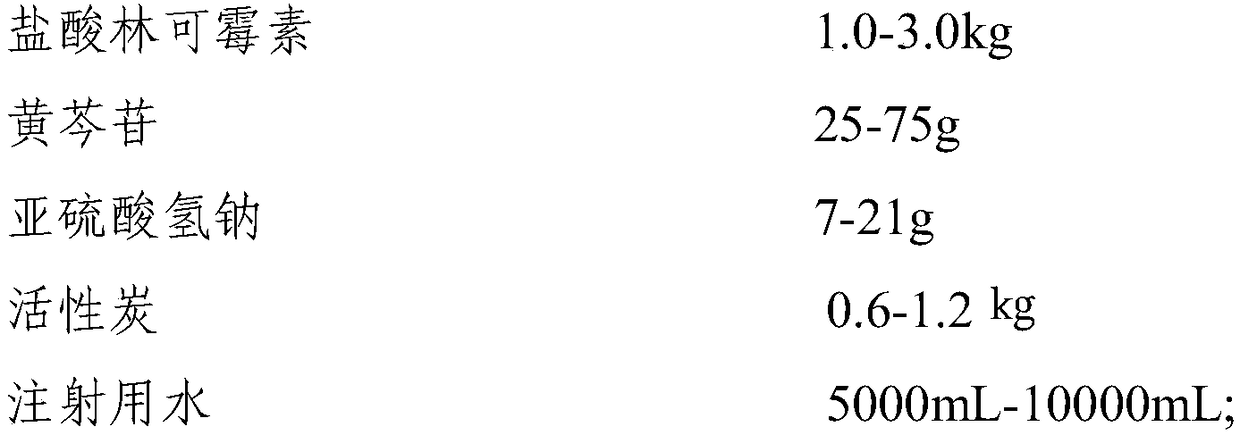

A medicinal injection of lincomycin hydrochloride composition and preparation method of its formula and medicinal preparation

InactiveCN105796584BSimple and fast operationGreat industrial valueAntibacterial agentsOrganic active ingredientsTherapeutic effectLincomycin Hydrochloride

Owner:安徽延寿堂药业有限公司

Manufacturing method for silicon thin-film solar cell

InactiveCN101364619BImprove photoelectric conversion efficiencyLow costFinal product manufactureSemiconductor devicesP type siliconSolar battery

The invention discloses a method for manufacturing a thin silicon film solar battery. The method comprises the following steps: P-type high-purity polysilicon with the purity of more than 99.999% is firstly crushed into high-purity polysilicon powder with the granularity of 5-50 micron; the polysilicon powder is applied on a substrate combined with an aluminum electrode to form a high-purity p-type silicon micron granular film; silicon micron granules and a metal conductive bottom electrode interface are alloyed through the anneal technology; then an n-type silicon layer is deposited on the silicon granular single-layer film, or an intrinsic silicon layer and the n-type silicon layer are deposited in sequence; and finally a transparent conductive electrode layer is deposited. The method adopts the unique technology of crushing and applying high-purity polysilicon raw material to realize the deposition of the high-quality polysilicon film on substrates such as glass, plastics, metal sheets, etc., and the technological method for manufacturing the solar battery has the advantages of simplicity, low manufacture cost, high efficiency of photoelectric conversion and broad value of industrialization.

Owner:HUNAN UNIV

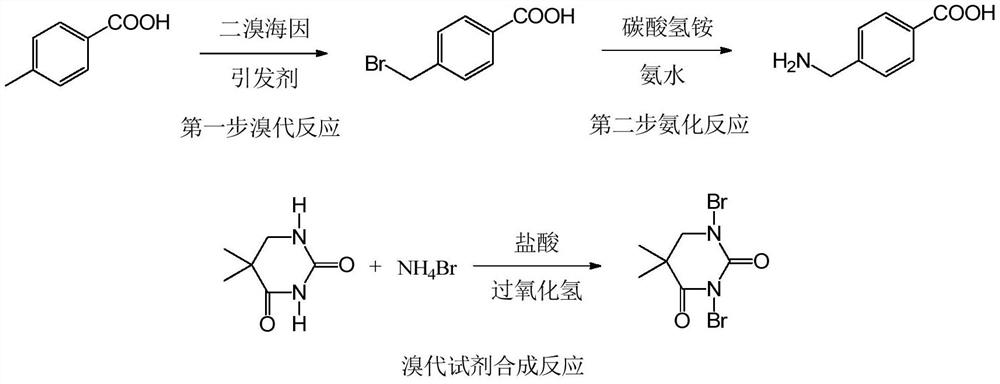

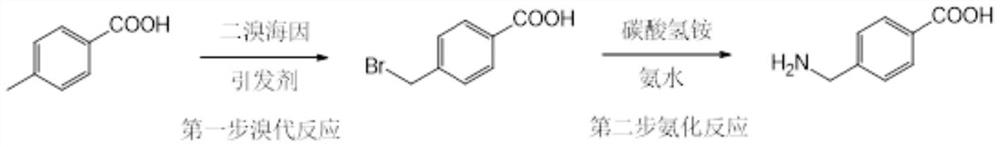

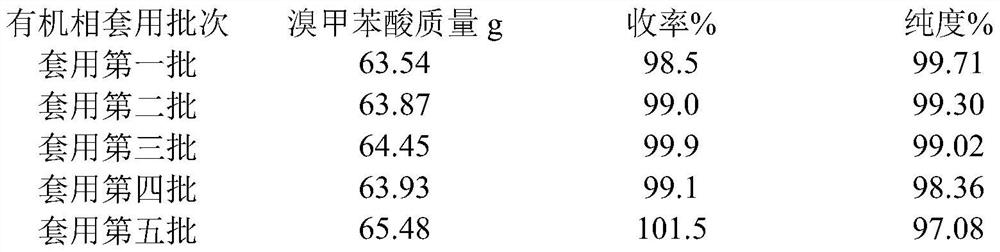

Method for synthesizing 4-(aminomethyl)benzoic acid

ActiveCN113929588AIncrease profitLow costOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidMethyl benzene

The invention belongs to the technical field of medicine synthesis, and particularly relates to a method for synthesizing 4-(aminomethyl)benzoic acid by using dibromohydantoin as a brominating agent. The method comprises the following steps: carrying out bromination reaction on p-toluic acid and dibromohydantoin in a solvent by using an initiator, carrying out suction filtration after the reaction, collecting a filter cake to obtain p-bromomethyl benzoic acid, and carrying out ammonification reaction on the p-bromomethyl benzoic acid to obtain the 4-(aminomethyl)benzoic acid. The 4-(aminomethyl)benzoic acid obtained by using the method is high in purity and low in cost, production safety is improved, the complexity and depreciation rate of equipment are reduced, and the method has a relatively large industrial practical value; and brominating reagents, namely hydantoin and bromine elements are well recycled, so production cost is reduced.

Owner:SHENYANG RES INST OF CHEM IND

A method for preparing 2-nitro-4-thiamphenicol benzoic acid

ActiveCN104557639BReduce usageHigh reaction yieldOrganic chemistryOrganic compound preparationBenzoic acidOxygen

The invention discloses a novel method of preparing 2-nitro-4-methylsulfonyl benzoic acid. The target product which is 2-nitro-4-methylsulfonyl benzoic acid is prepared by carrying out reaction by adopting an oxidation reaction device with a self-priming stirrer, wherein 2-nitro-4-methylsulfonyltoluene is used as the raw material, sulfuric acid is used as a reaction medium, a transition metal oxide is used as the catalyst, and oxygen is introduced in the course of reaction. The method provided by the invention has the advantage that the reaction condition is easy to control, the production cost is low, and the amount of the generated three wastes is reduced.

Owner:SHENYANG RES INST OF CHEM IND

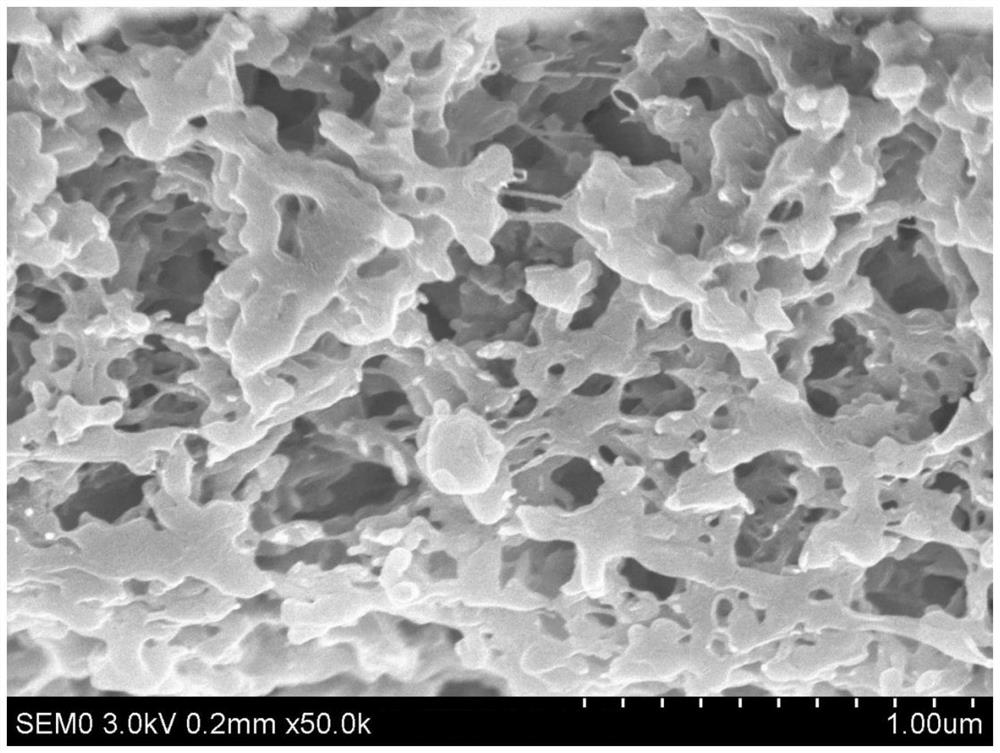

Preparation method of polyolefin hollow fiber membrane

PendingCN114733360AHigh mechanical strengthGreat industrial valueSemi-permeable membranesPolymer sciencePolyolefin

The invention provides a preparation method of a polyolefin hollow fiber membrane, which comprises the following steps: preparing a membrane casting solution, and extruding the membrane casting solution through a die head to form a molded product with an inner surface and an outer surface, performing split-phase curing on the molded product at a certain cooling rate; carrying out quenching and extraction treatment to obtain an original film; the original membrane comprises a supporting layer and a separation layer, the separation layer is provided with holes, and the average hole diameter of the separation layer is 5-60 nm; the original membrane is placed in an environment with the temperature not higher than 50 DEG C for low-temperature drying treatment, so that the content of extract liquor in the original membrane is not higher than 5%; and finally, carrying out high-temperature setting to prepare the hollow fiber membrane with high gas mass transfer rate. According to the preparation method, the extraction liquid can be removed within a short time, the integrity of the hollow fiber membrane can be guaranteed, the hole collapse phenomenon is avoided, the prepared hollow fiber membrane has the high gas mass transfer rate, and the preparation method is rapid, effective, easy to operate and suitable for large-scale popularization.

Owner:杭州费尔新材料有限公司

Process for producing high-strength high-ductility hard polyvinyl chloride

This invention pertains to the field of material technology, in particular relates to a preparation method of high strength and high tenacity rigid polyvinyl chloride. The specific steps are as follows: mixing a carbon nano tube with concentrated nitric acid under certain conditions for obtaining an acidulated carbon nano tube; mixing the acidulated carbon nano tube with SOCl2 for obtaining the carbon nano tube with an acyl chloride group; and then mixing polycaprolactone with the carbon nano tube with the acyl chloride group for obtaining the carbon nano tube of polycaprolactone chemical grafting. Polyvinyl chloride power, plasticizing agent, composite stabilizer, filling agent, whitening agent, lubricating agent and the carbon nano tube are pre-mixed in certain proportion in a high-speed mixer, and then a dual-roller mill is used for plasticizing and finally the high strength and high tenacity rigid polyvinyl chloride is obtained by rolling under certain pressure. The invention has the advantages of available raw materials, simple process, using existing industrial equipment of polyvinyl chloride, relatively low price, excellent product performances and important application value.

Owner:TONGJI UNIV

Second structure strengthening based austenitic alloy and preparation method thereof

The invention relates to a second structure strengthening based austenitic alloy, which comprises the following chemical components by mass percentage: 50-75 of Fe-Cr-Ni alloy powder and 25-50 of Co based alloy powder. The preparation method of the austenitic alloy mainly includes: mixing the Fe-Cr-Ni alloy powder with the Co based alloy powder evenly; loading the alloy powder into a graphite die,conducting spark plasma sintering under a pressure of 30-50MPa and a temperature of 1000-1150DEG C, and controlling the heating rate at 50DEG C / min, the sintering heat preservation time at 5-20min, and the sintering vacuum degree at less than or equal to 8Pa, and then performing furnace cooling, thus obtaining the second structure strengthening based austenitic alloy. The method provided by the invention has the characteristics of simple process, short flow, low production cost, energy saving and environmental protection. The prepared austenitic alloy not only has good room temperature strength and plasticity, but also can maximumly avoid performance deterioration caused by crystal grain growth.

Owner:YANSHAN UNIV

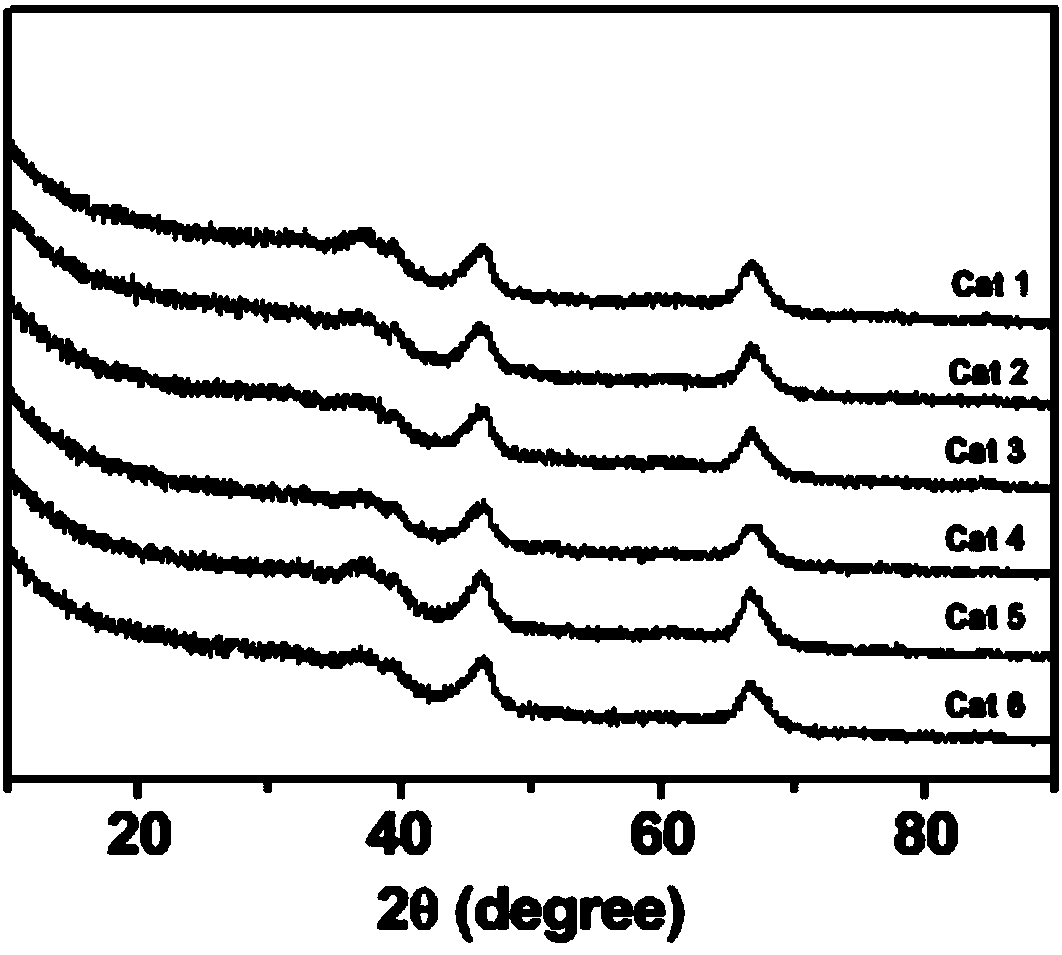

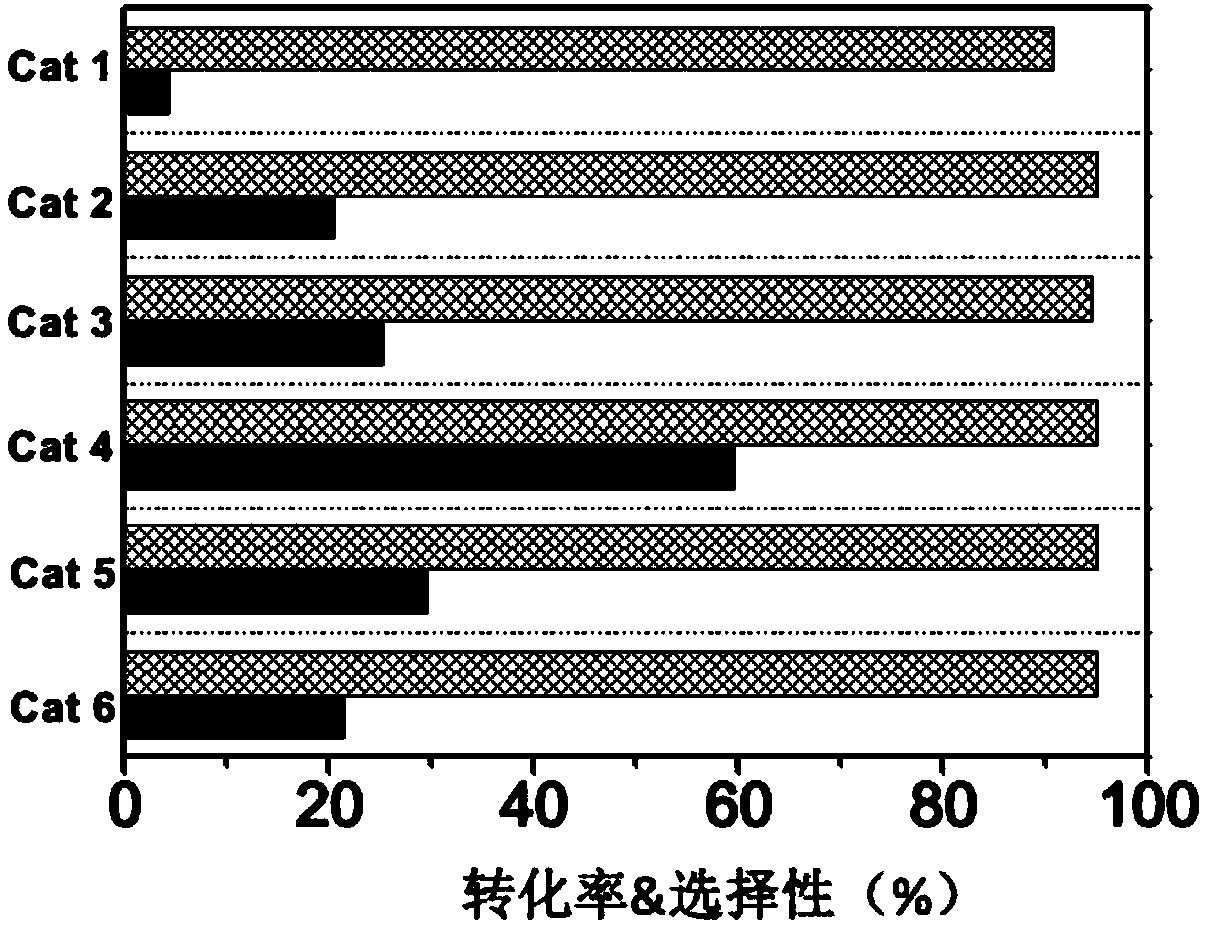

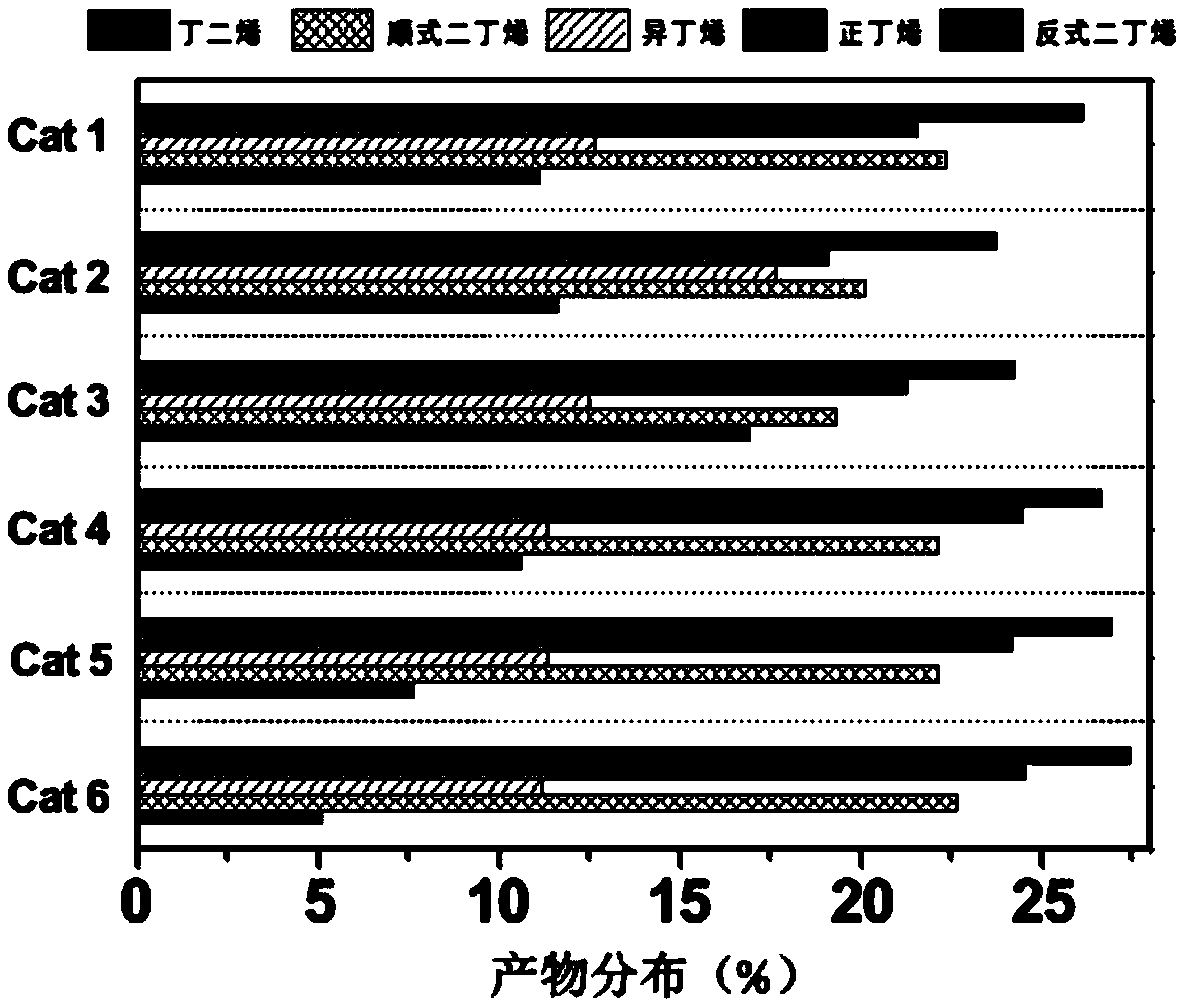

Method for preparing butene and butadiene by catalytic dehydrogenation of butane

ActiveCN109608301ALow costGreat industrial valueMolecular sieve catalystsMolecular sieve catalystButeneActive component

The invention provides a method for preparing butene and butadiene by catalytic dehydrogenation of butane. According to the method provided by the invention, a dual active component composite catalystcontaining zirconium and gallium is used, high-efficiency dehydrogenation is performed on the butane, the selectivity of the butadiene in the product reaches 17 %, the selectivity of the total butenereaches 81.5%, and the catalyst shows good stability and reproducibility at high temperatures.

Owner:SUZHOU UNIV

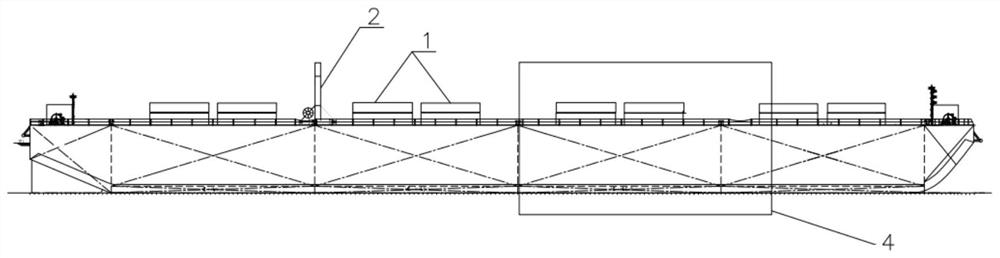

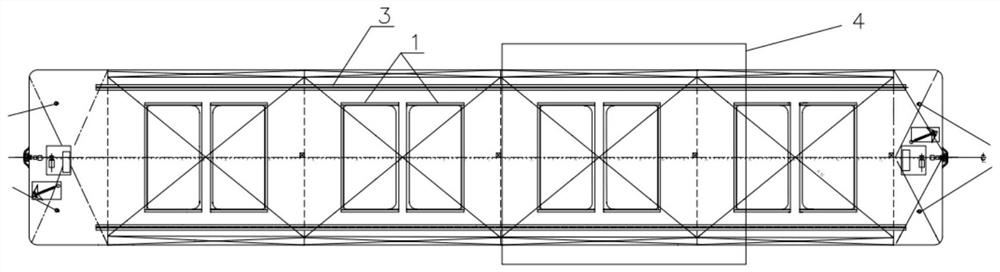

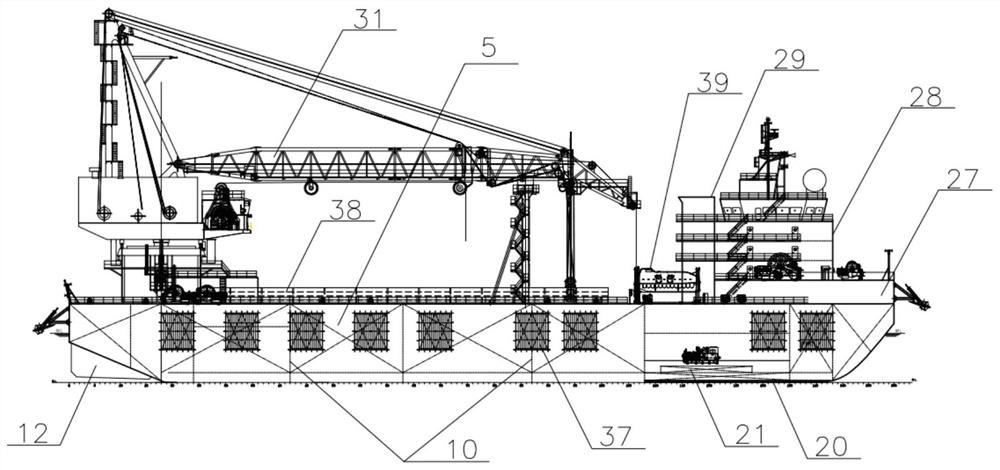

A modification method based on an unmanned cargo barge and a bottom-mounted full-slewing crane barge

The invention discloses a modification method based on an unmanned cargo barge and a modified bottom-sitting full-turn lifting barge. The transformation method is as follows: cut off the section of the parallel mid-body cargo hold area of the unmanned cargo barge, and combine the two front and rear sections of the cargo barge after the parallel mid-body section is cut off to form the main hull of the bottom-mounted lifting barge , and take reinforcement measures for the part of the main hull of the bottom-mounted lifting barge; add engine room, pump room, ballast tank, ballast system and oil-water tank below the main deck; set up a main crane at the tail above the main deck, and add a Chimney, forecastle and deckhouse; additional positioning anchor system and outfitting equipment. Transforming the unmanned cargo barge into a bottom-mounted full-slewing crane barge can not only meet the operation requirements of different lifting weights and different lifting heights for offshore floating lifting operations, but also meet the rescue and salvage of ships stranded and wrecked in shallow water reef areas Or the bottom-mounted lifting operation requirements of special engineering projects such as wind power equipment installation in coastal shoal waters, the project is widely applicable.

Owner:708TH RES INST OF CSSC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com