Method for preparing titanium-based composite material by sintering pre-dispersed graphite composite titanium hydride

A technology of titanium-based composite materials and titanium hydride, which is applied in the field of powder metallurgy forming TiC-reinforced titanium-based composite materials, can solve the problems of low tensile plasticity, high cost, and cost reduction, and achieve high tensile strength, improved performance, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

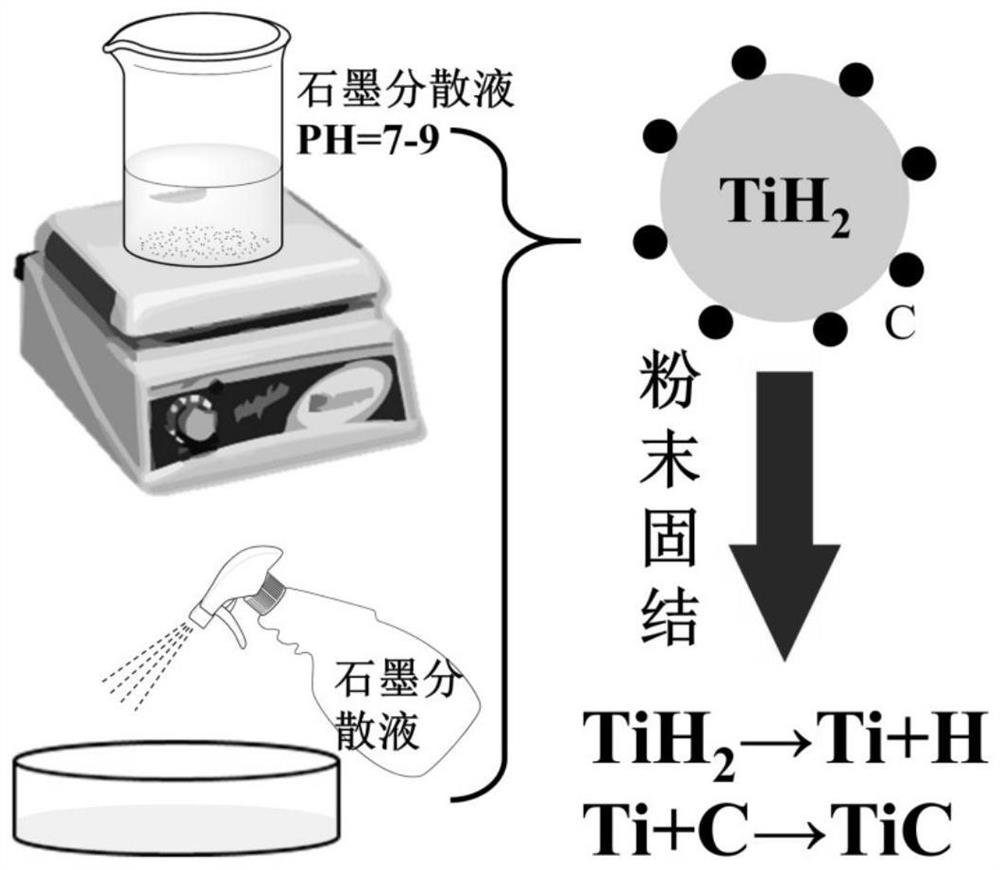

[0044] A method for preparing a titanium-based composite material by sintering pre-dispersed graphite composite titanium hydride powder, comprising the following steps:

[0045] The raw materials used are as follows: polyvinylpyrrolidone (PVP-K30), titanium hydride powder (75 μm), graphite powder (2 μm), deionized water.

[0046] (1) Graphite liquid phase deagglomeration: first, according to the TiC content of 6vol.%, weigh 0.3 parts by mass of graphite powder and slowly pour it into 100 parts by volume of deionized water, and then slowly pour it into 0.4 The mass part of PVP powder was stirred for 30 minutes, and the graphite dispersion was ultrasonically oscillated for 30 minutes to obtain the graphite powder dispersion.

[0047] (2) Graphite attachment: First, weigh 20 parts by mass of titanium hydride powder and evenly spread it on a petri dish. Afterwards, pour the graphite dispersion into the nano sprayer, ensure that the spray direction is about 45° from the bottom sur...

Embodiment 2

[0051] A method for preparing a titanium-based composite material by sintering pre-dispersed graphite composite titanium hydride powder, comprising the following steps:

[0052] The raw materials used in this example are as follows: polyvinylpyrrolidone (PVP-K30), titanium hydride powder (75 μm), graphite powder (100 nm), deionized water, and ammonia water.

[0053] (1) Graphite liquid phase deagglomeration: First, according to the TiC content of 10vol.%, take 0.42 parts by mass of graphite powder and slowly pour it into 100 parts by volume of deionized water, and then slowly pour it into 0.65 The mass part of PVP powder was stirred for 30 minutes, and the graphite dispersion was ultrasonically oscillated for 30 minutes to obtain the graphite powder dispersion.

[0054] (2) Graphite adhesion: first, slowly drip ammonia water into the graphite dispersion prepared in step (1) and measure the pH value, and adjust the pH of the graphite dispersion to 9. Afterwards, weigh 20 parts...

Embodiment 3

[0058] A method for preparing a titanium-based composite material by sintering pre-dispersed graphite composite titanium hydride powder, comprising the following steps:

[0059] The raw materials used in this example are as follows: polyvinylpyrrolidone (PVP-K30), titanium hydride powder (75 μm), graphite powder (3 μm), deionized water.

[0060] (1) Graphite liquid phase deagglomeration: First, weigh 0.06 parts by mass of graphite powder according to the TiC content of 0.5vol.%, slowly pour it into 100 parts by volume of deionized water, stir it with a magnetic stirrer at a speed of 500rpm for 15min, and then slowly pour it into 0.3 parts by mass of PVP powder were stirred for 30 minutes, and the graphite dispersion was ultrasonically oscillated for 30 minutes to obtain a graphite powder dispersion.

[0061] (2) Graphite attachment: First, weigh 20 parts by mass of titanium hydride powder and evenly spread it on a petri dish. Afterwards, pour the graphite dispersion into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com