Method for preparing butene and butadiene by catalytic dehydrogenation of butane

A technology for catalytic dehydrogenation and butadiene, applied in chemical instruments and methods, catalyst activation/preparation, catalysts, etc., can solve problems such as deactivation, easy carbon deposition, environmental pollution, etc., and achieve great industrial value and application prospects, Good stability and reproducibility, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A certain amount of zirconium nitrate was weighed and prepared into a solution, and then impregnated with equal volume on the silicon-aluminum composite carrier. After impregnation, it was aged for 1 hour and then dried overnight in an oven at 100°C. The obtained catalyst was calcined at 750°C for 2 hours to obtain catalyst cat 1.

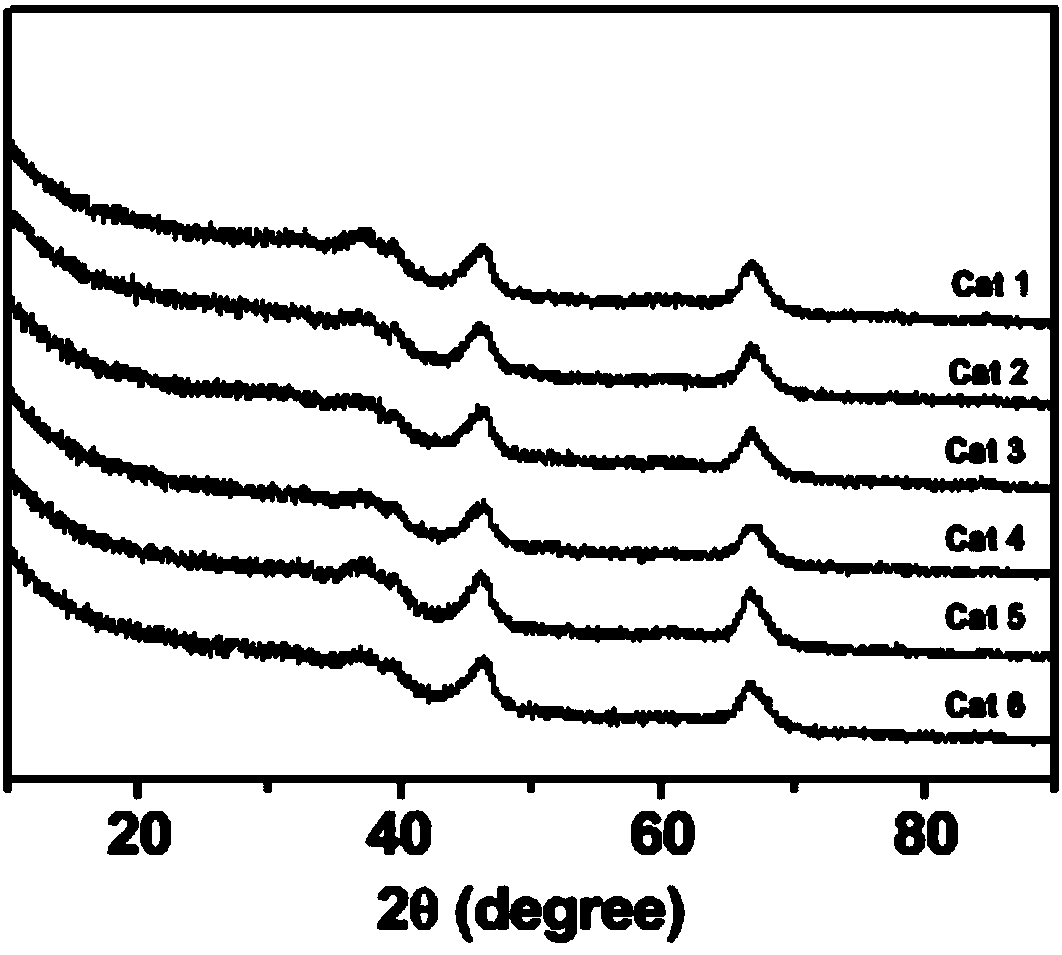

[0034] The mass fraction of zirconium in the catalyst obtained in the present embodiment is 4.47%. The specific surface area, pore volume and pore diameter of the catalyst are as shown in Table 1, and the X-ray diffraction pattern is as shown in Table 1. figure 1 shown.

Embodiment 2

[0036] According to the mass ratio of metal zirconium and metal gallium being 3.5:1, a certain amount of zirconium and gallium precursors, zirconium nitrate and gallium nitrate, were weighed and prepared into a mixed solution, and then impregnated in equal volume on the silicon-aluminum composite carrier. After impregnation, it was aged for 1 hour and then dried overnight in an oven at 100°C. The obtained catalyst was calcined at 750°C for 2 hours to obtain catalyst cat 2.

[0037]The mass fraction of zirconium in the catalyst obtained in this example was 3.53%, and the mass fraction of gallium was 0.81%. The specific surface area, pore volume and pore diameter of this catalyst are as shown in Table 1, and the X-ray diffraction figure is as follows figure 1 shown.

Embodiment 3

[0039] According to the mass ratio of metal zirconium and metal gallium as 2:2.5, a certain amount of zirconium and gallium precursors zirconium nitrate and gallium nitrate were weighed and prepared into a mixed solution, and then impregnated in equal volume on the silicon-aluminum composite carrier. After impregnation, it was aged for 1 hour and then dried overnight in an oven at 100°C. The obtained catalyst was calcined at 750°C for 2 hours to obtain catalyst cat 3.

[0040] The mass fraction of zirconium in the catalyst obtained in this example was 1.89%, and the mass fraction of gallium was 2.23%. The specific surface area, pore volume and pore diameter of this catalyst are as shown in Table 1, and the X-ray diffraction figure is as follows figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com