A modification method based on an unmanned cargo barge and a bottom-mounted full-slewing crane barge

A bottom-sitting and crane technology, applied to barges/flat-bottomed boats, etc., can solve the problems of long construction period, affecting the progress of the project, and large funds, etc., and achieve the effect of short construction period, wide application range and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

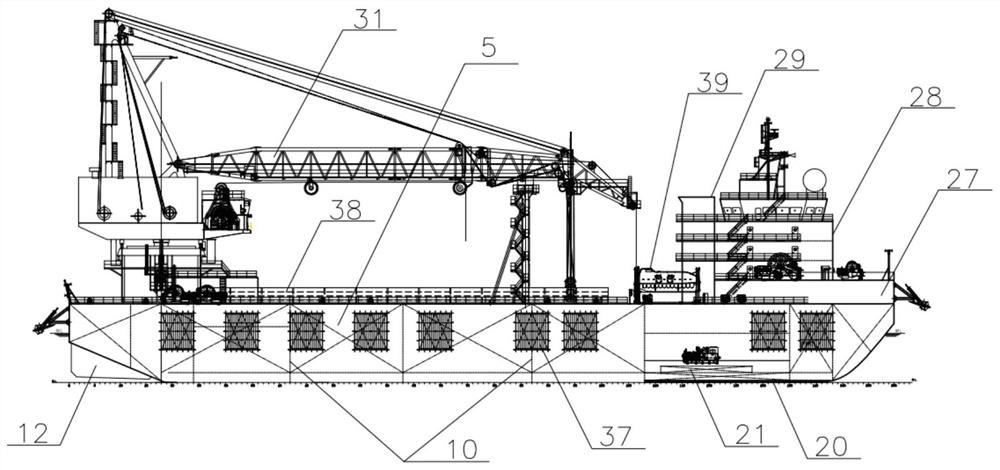

[0045] The present invention transforms the unmanned cargo barge into a bottom-mounted full-rotation lifting barge. The full-rotation lifting barge mainly includes the main hull of the barge, a full-rotation lifting device, an operation deck, a forecastle and a deckhouse. Functional compartments such as engine room, pump room, auxiliary equipment room and oil water tank are arranged inside. The specific modification methods are as follows, and it should be noted that the sequence of steps included in the following modification methods is not limited, and can be reasonably arranged according to the actual situation.

[0046] 1) Transformation of the main hull of the unmanned barge:

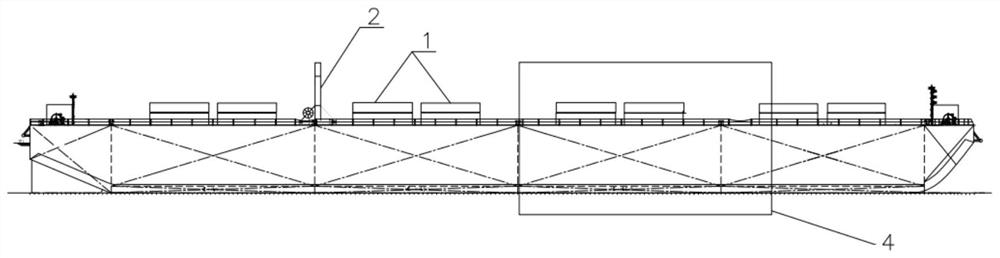

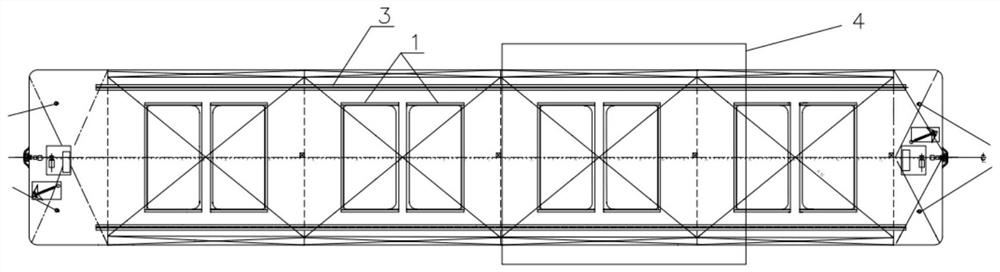

[0047]The original cargo barge of this embodiment has a length of ~171m, a molded width of 32m, and a molded depth of 12m, such as Figure 1a -b shown. Between the head and tail anti-collision bulkheads of the original cargo barge is the warehouse area, with four large cargo holds, and two large h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com