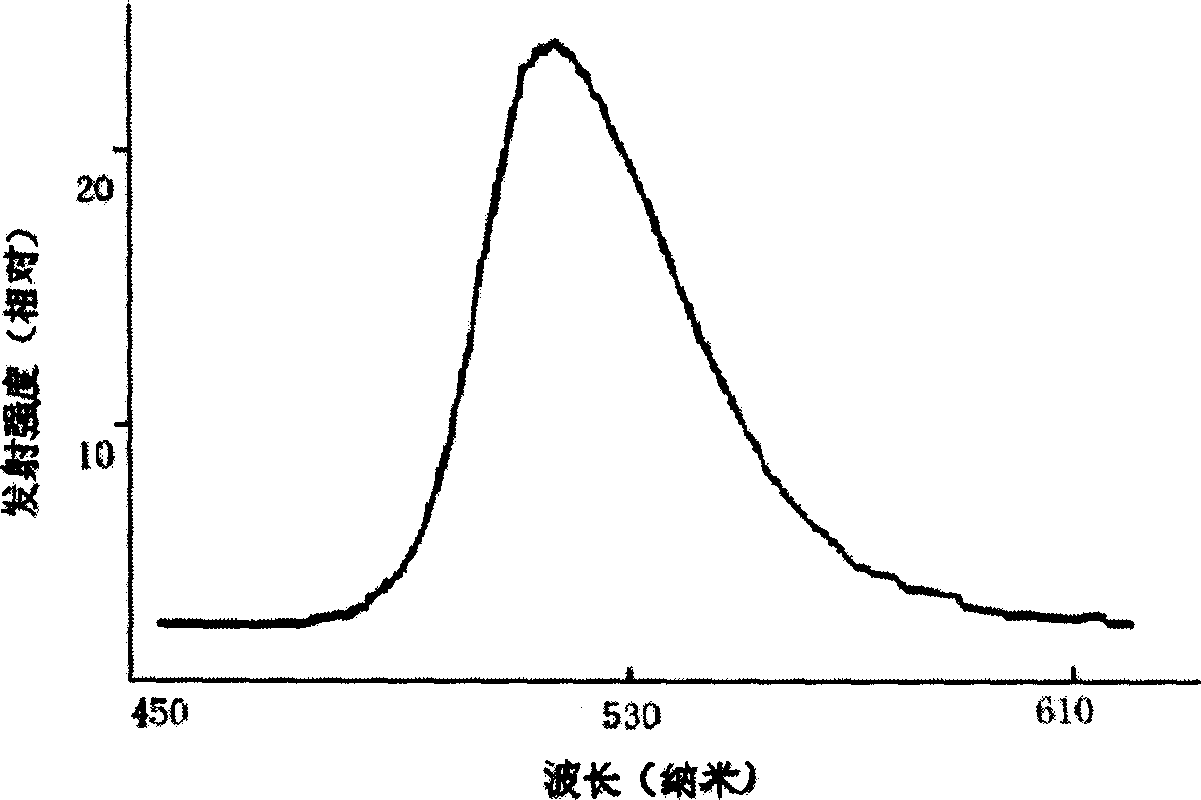

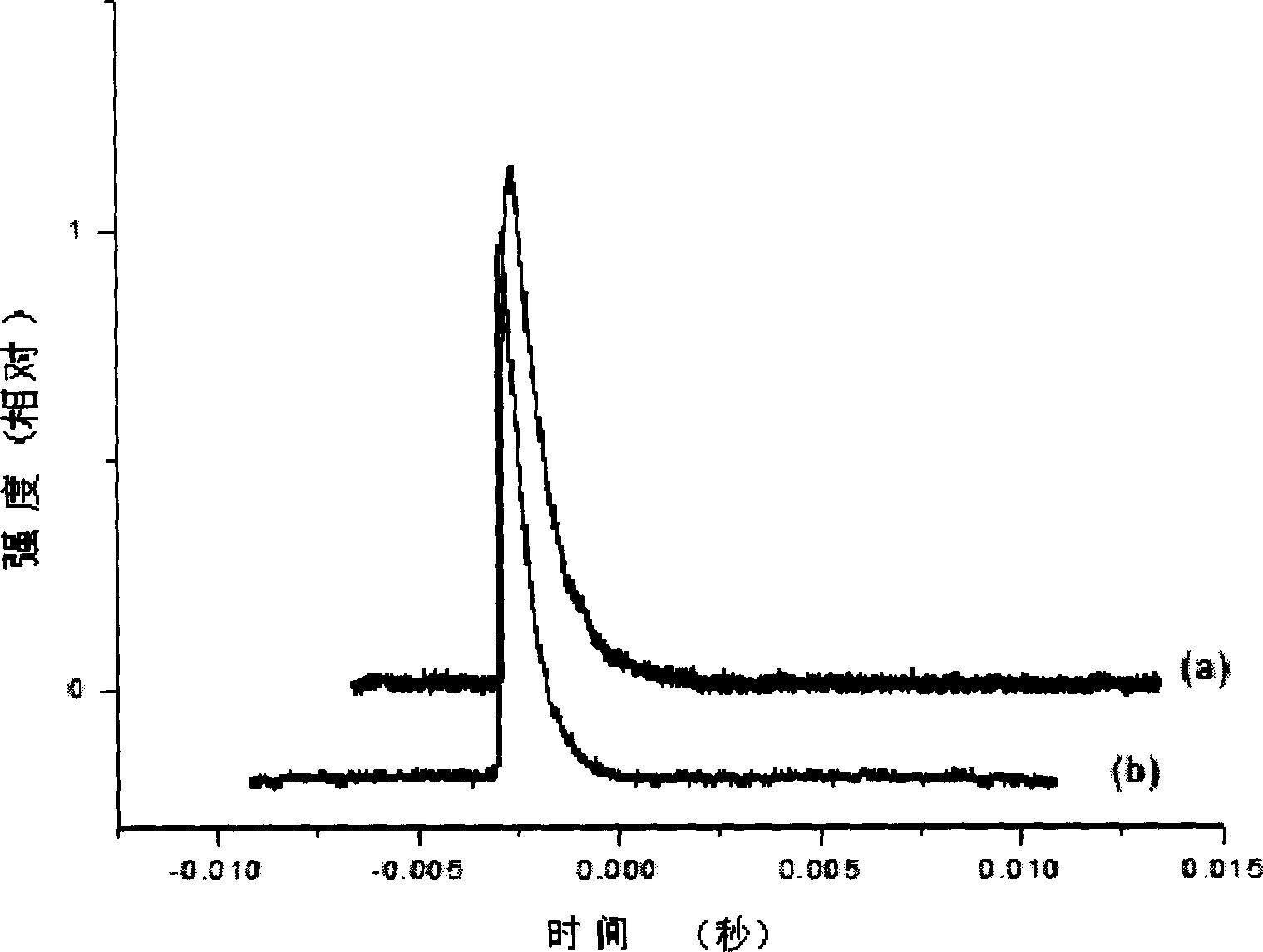

Short-afterglow zinc-manganese silicate green fluorescent powder and its preparing method

A technology of zinc manganese silicate and phosphor powder, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of unsuitable manufacturing process of display devices, and achieve the effect of large industrial practical value, low price, and shortening fluorescent life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]First prepare nano silicon dioxide containing manganese ions: use tetraethoxysilane (orthosilicate) as starting raw material, according to the formula Zn 2-2x SiO 4 : the ratio of 2xMn, the ratio of silicon component and manganese component is 1: 2x molar ratio, in the present embodiment, x=0.005; Earlier tetraethoxysilane, manganese nitrate solution, deionized water and 95% (V / V) ethanol is mixed and mixed evenly with a mixer, then heated in a water bath at 60 degrees Celsius to form a sol, and gradually transform into a gel as time goes by, and the gel is ground into powder after being dried at 100 degrees Celsius, and the obtained dry coagulation The rubber powder is heat-treated at 400 degrees Celsius to obtain an amorphous nano-silica material with a particle size of about 5 nanometers and manganese ions evenly distributed in it; the amount of deionized water is subject to the complete hydrolysis of tetraethoxysilane, and the amount of alcohol Tetraethoxysilane:al...

Embodiment 2

[0033] With reference to embodiment 1, wherein:

[0034] In the preparation of the amorphous nano-silica suspension containing manganese ions, the ratio of the silicon component to the manganese component is 1: 2x molar ratio, x=0.01;

[0035] In the preparation of solution 1, the consumption of the suspension of amorphous nano silicon dioxide is measured by the molar ratio of 1: 0.01 by the ratio of zinc: manganese;

[0036] In the preparation of solution 2, the consumption of aqueous urea solution is metered (about 200 milliliters) by the mol ratio of urea: nitrate=2.5:5;

[0037] Other conditions are identical with embodiment 1.

[0038] Finally, the product 2 is obtained with a grayish black color. It shows that the reaction temperature is too high and the oxidizing property of the flame atmosphere is too strong, a small amount of manganese ions are oxidized, and the valence state changes.

[0039] Product 2 was subjected to X-ray diffraction analysis, and the same resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com