Process for producing high-strength high-ductility hard polyvinyl chloride

A technology of rigid polyvinyl chloride and polyvinyl chloride, which is applied in the field of materials to achieve the effects of improving impact strength, increasing stiffness, and large industrial practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

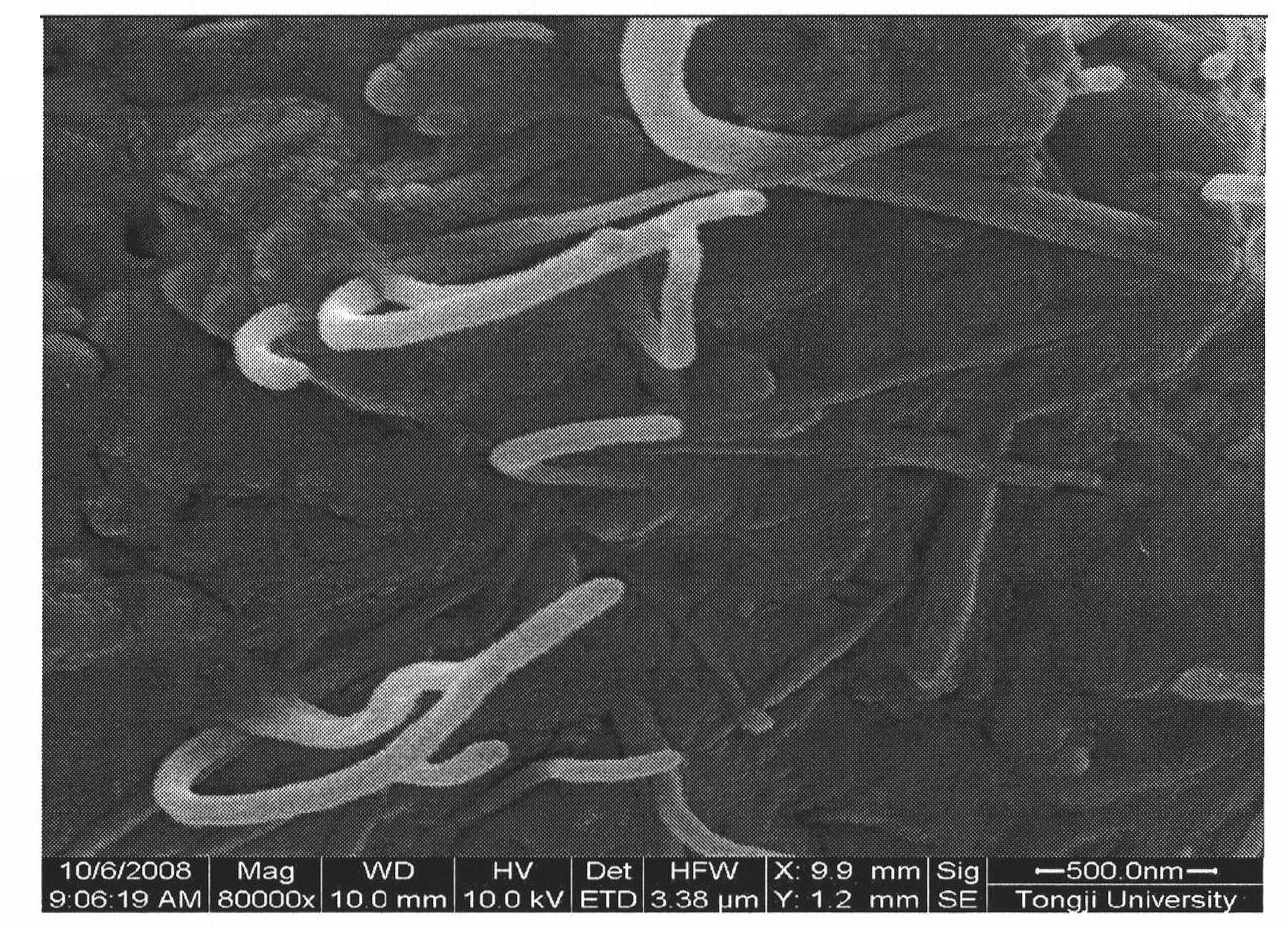

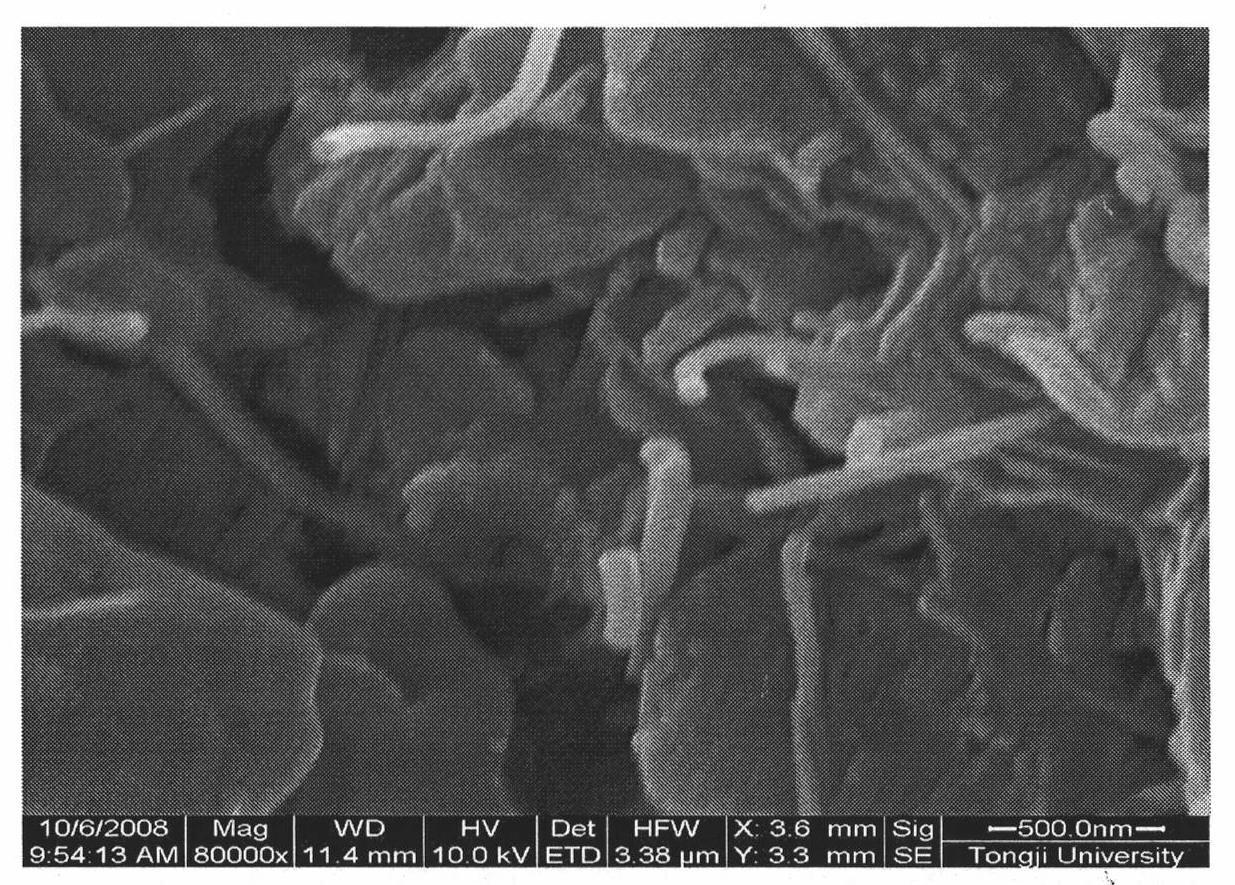

[0038] (a) 1.2 g of MWNTs with a diameter of 30-50 nm and a length of 15 μm were mixed with 120 ml of concentrated nitric acid, ultrasonically oscillated for 10 minutes, and reacted under reflux at 70° C. for 24 hours. After the mixture was cooled, it was diluted with distilled water, vacuum-filtered with a cellulose membrane (pore size 0.45 μm) until the pH value of the filtrate was neutral, and the filter cake was vacuum-dried at 60° C. for 12 hours.

[0039] (b) Mix 1gMWNTs-COOH obtained in the first step with 40mlSOCl 2 Reflux and stir at 65°C for 24 hours. After cooling, the reaction mixture was diluted with anhydrous tetrahydrofuran, filtered through a polyvinylidene fluoride membrane (pore size 0.45 μm), repeated three times, and dried in vacuum at room temperature for 2 hours.

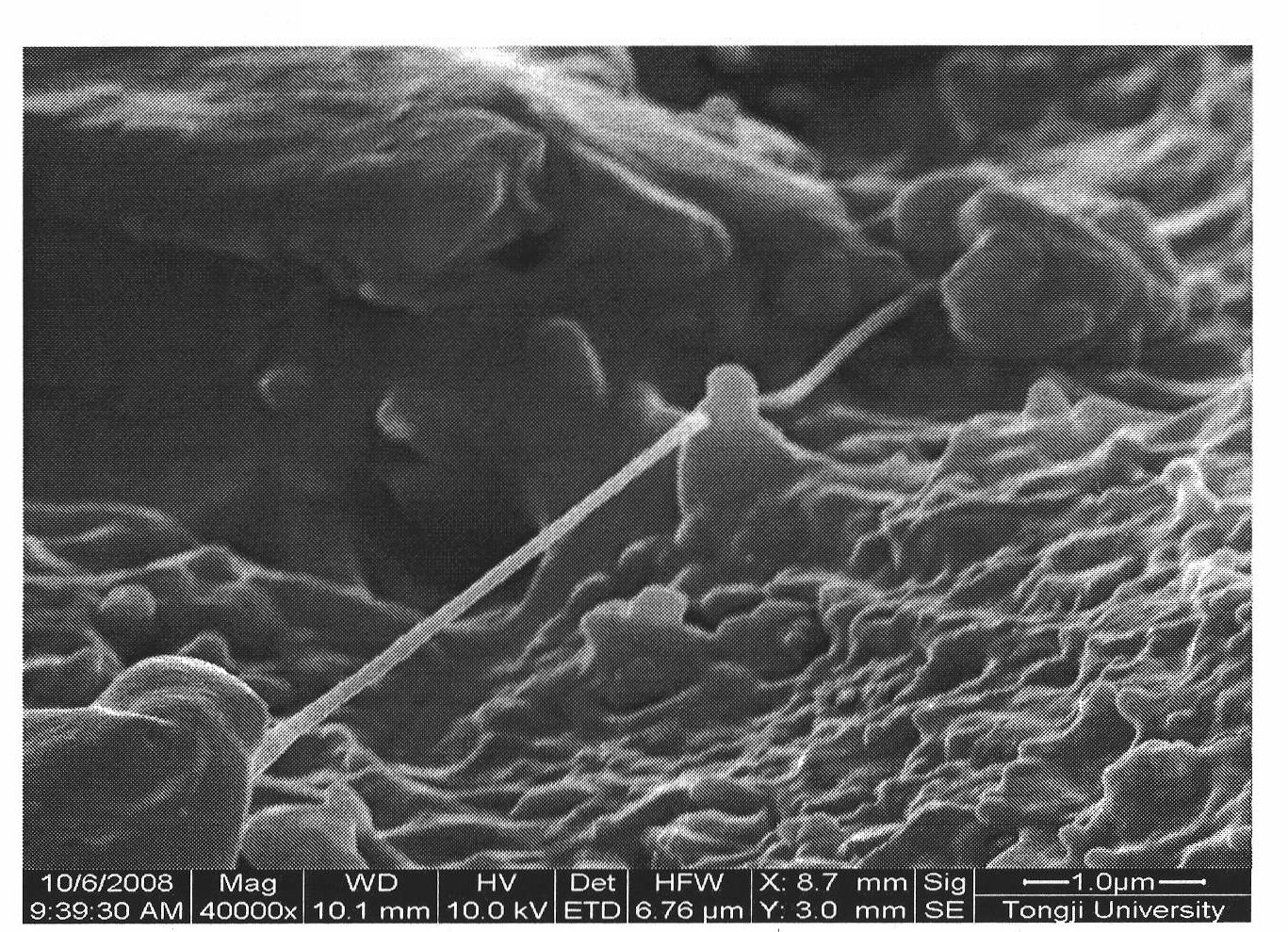

[0040] (c) 1 g of MWNTs-COCl after vacuum drying and 10 g of polycaprolactone were stirred and reacted in 10 mL of 1,2-dichlorobenzene at 120° C. for 60 hours. Wash with hot absolute ethanol, ...

Embodiment 2

[0043] (a) 1.2 g of MWNTs with a tube diameter of 8-15 nm and a length of 50 μm were mixed with 120 ml of concentrated nitric acid, ultrasonically oscillated for 10 minutes, and reacted under reflux at 70° C. for 24 hours. After the mixture was cooled, it was diluted with distilled water, vacuum-filtered with a cellulose membrane (pore size 0.45 μm) until the pH value of the filtrate was neutral, and the filter cake was vacuum-dried at 60° C. for 12 hours.

[0044] (b) Mix 1gMWNTs-COOH obtained in the first step with 40mlSOCl 2 Reflux and stir at 65°C for 24 hours. After cooling, the reaction mixture was diluted with anhydrous tetrahydrofuran, filtered through a polypropylene filter (pore size 0.45 μm), repeated three times, and vacuum-dried at room temperature for 2 hours.

[0045] (c) 1 g of MWNTs-COCl after vacuum drying and 10 g of polycaprolactone were stirred and reacted in 10 mL of 1,2-dichlorobenzene at 120° C. for 60 hours. Wash with hot absolute ethanol, and suction...

Embodiment 3

[0048](a) 1.2 g of MWNTs with a tube diameter of 30-50 nm and a length of 15 μm were mixed with 120 ml of concentrated nitric acid, ultrasonically oscillated for 5 minutes, and reacted under reflux at 70° C. for 24 hours. After the mixture was cooled, it was diluted with distilled water, vacuum-filtered with a cellulose membrane (pore size 0.45 μm) until the pH value of the filtrate was neutral, and the filter cake was vacuum-dried at 60° C. for 12 hours.

[0049] (b) Mix 1gMWNTs-COOH obtained in the first step with 40mlSOCl 2 Reflux and stir at 65°C for 24 hours, dilute the reaction mixture with anhydrous tetrahydrofuran after cooling, and suction filter with a polyvinylidene fluoride filter membrane (pore size 0.8 μm), repeat this process 3 times, and vacuum dry at room temperature for 2 hours.

[0050] (c) 1 g of MWNTs-COCl after vacuum drying and 10 g of polycaprolactone were stirred and reacted in 10 mL of tetrahydrofuran at 70° C. for 19 hours. Wash with hot absolute et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com