Second structure strengthening based austenitic alloy and preparation method thereof

An austenitic and cobalt-based alloy technology, applied in the field of powder metallurgy, can solve the problems that the two phases cannot coordinate deformation well, reduce material plasticity, and cannot form a perfect coherent relationship, so as to achieve short sintering time, increase matrix strength, The effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Fe-chromium-nickel alloy powder (composition: Fe-19.21Cr-10.34Ni-0.84Si-0.25Mn-0.024C) with a purity greater than 99.9% and a particle size of 50-150 μm and a purity greater than 99.9% and a particle size of 120-200 μm The cobalt-based alloy powder (the composition is Co-29Cr-4.4W-1.1Ni-1.1Si-1.1C-0.2Fe), according to the mass ratio of 1:1, was put into a mortar, stirred evenly for 0.5h, and weighed Take 80g of uniformly mixed powder and put it into a graphite mold, heat up at a rate of 50°C / min, hold at 1100°C for 10min, press at 50MPa, and vacuum at 8Pa for spark plasma sintering. austenitic alloys. Its tensile strength at room temperature is 970MPa, and its elongation after fracture is 24.67%.

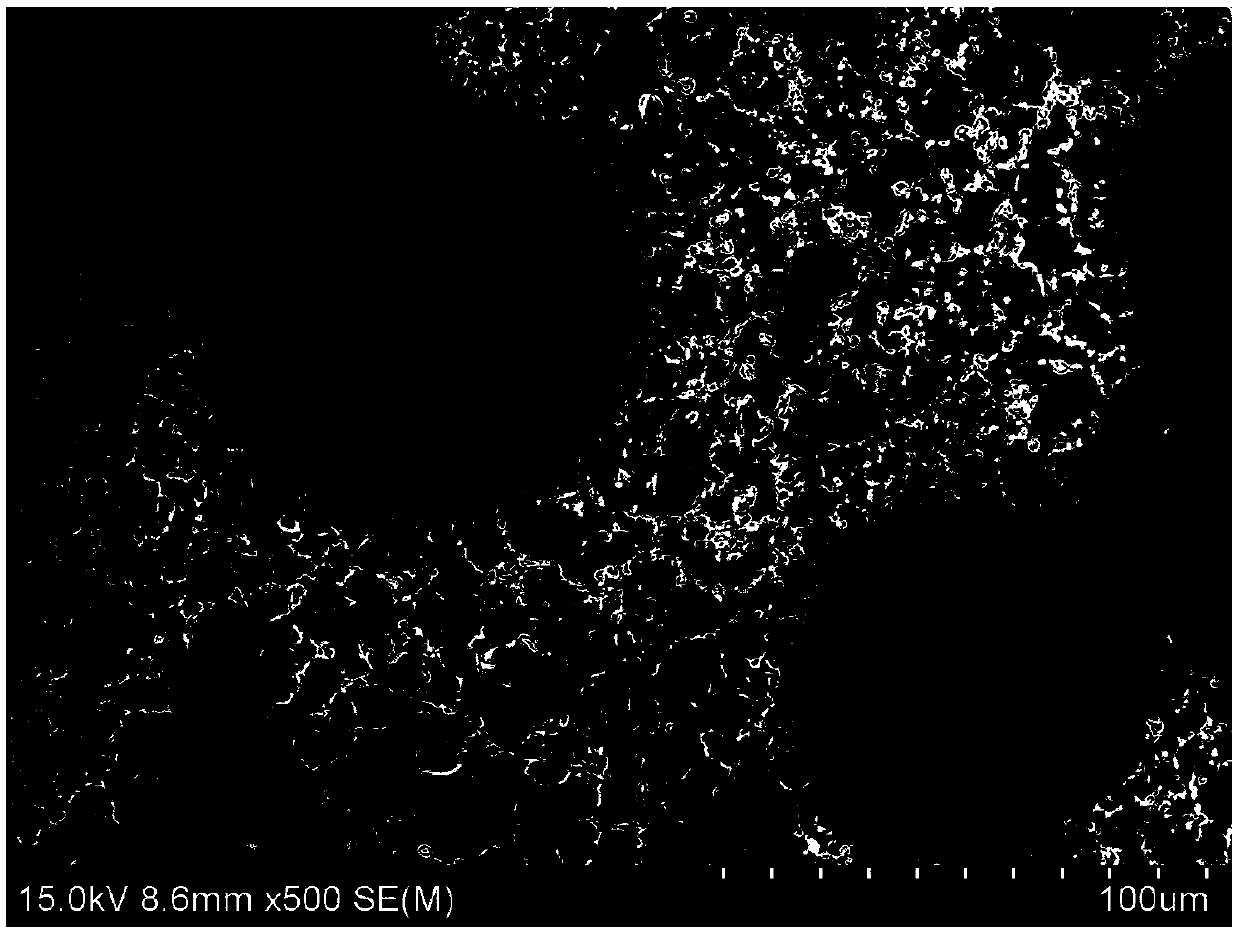

[0023] like figure 1 As shown, it shows that the interface between the cobalt-based alloy and the iron-chromium-nickel alloy is well bonded, and there is no obvious interface defect.

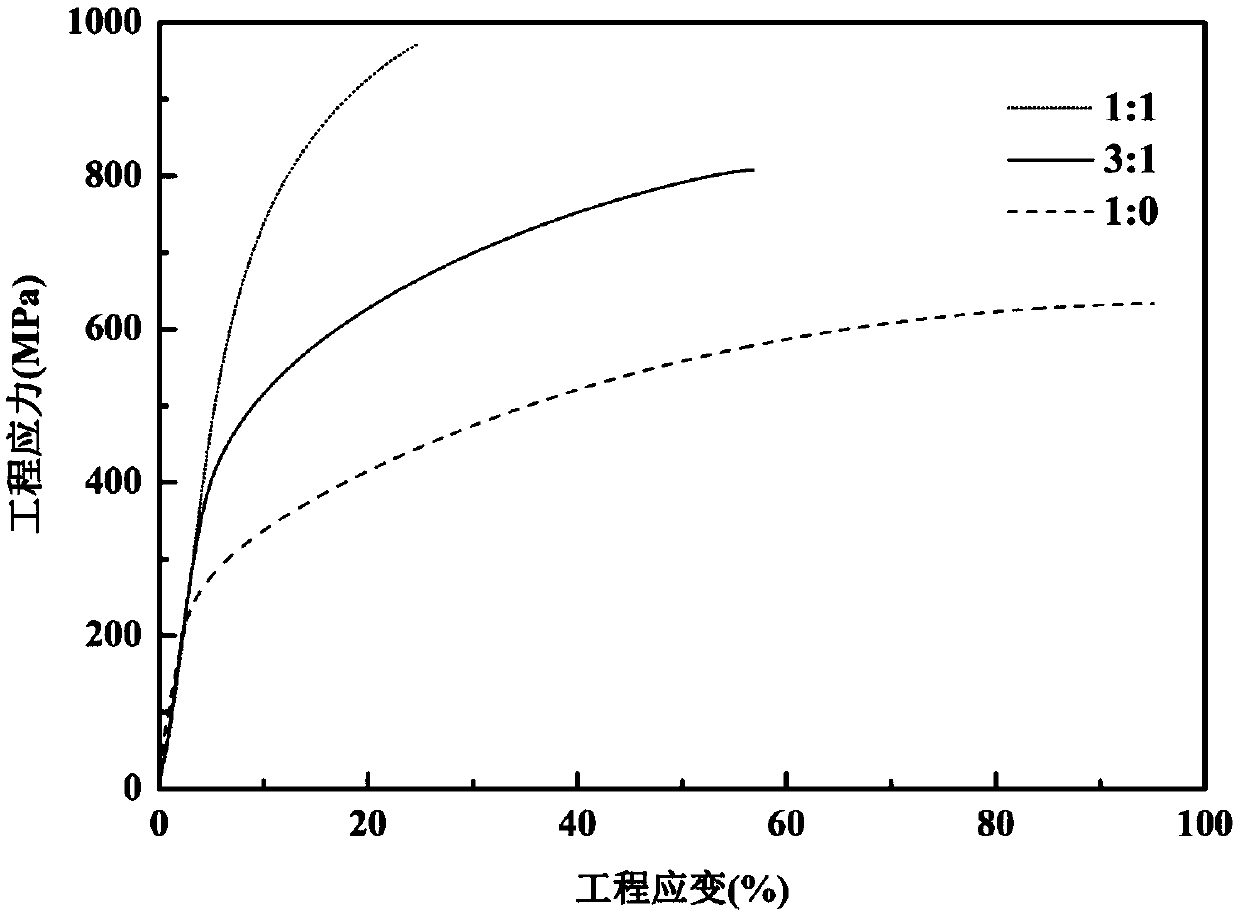

[0024] like figure 2 As shown, it shows that the strength of the prepared austenitic a...

Embodiment 2

[0027] Fe-chromium-nickel alloy powder (composition: Fe-19.21Cr-10.34Ni-0.84Si-0.25Mn-0.024C) with a purity greater than 99.9% and a particle size of 50-150 μm and a purity greater than 99.9% and a particle size of 120-200 μm The cobalt-based alloy powder (the composition is Co-29Cr-4.4W-1.1Ni-1.1Si-1.1C-0.2Fe), according to the ratio of 3:1 by mass, was put into a mortar and stirred evenly for 1h. Weigh 80g of uniformly mixed powder and put it into a graphite mould, heat up at a rate of 50°C / min, hold at 1150°C for 5min, pressure 50MPa, and vacuum 8Pa for discharge plasma sintering, and obtain a product based on the second Austenitic alloys strengthened by similar structures. Its tensile strength at room temperature is 800MPa, and its elongation after fracture is 56.83%.

Embodiment 3

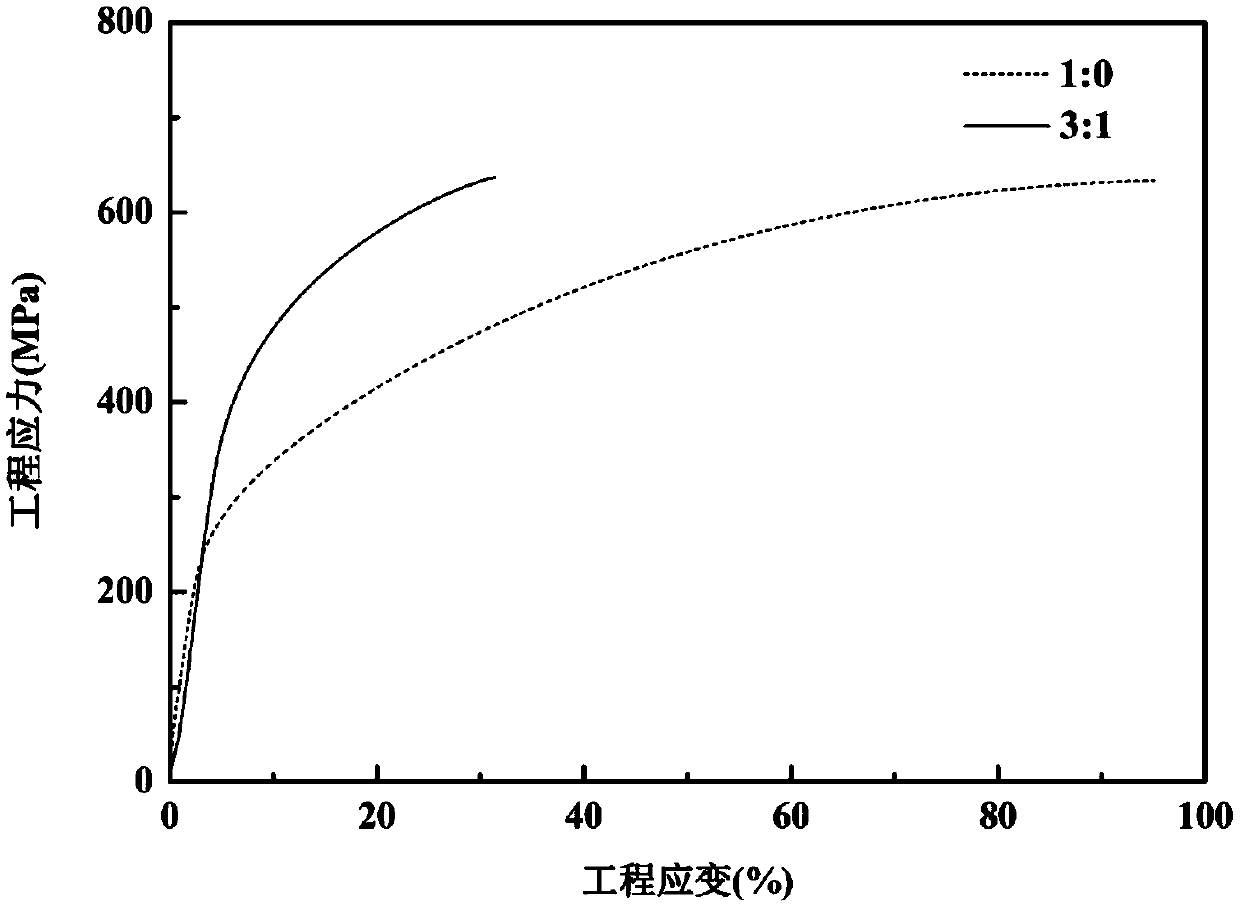

[0029] Fe-chromium-nickel alloy powder (composition: Fe-19.21Cr-10.34Ni-0.84Si-0.25Mn-0.024C) with a purity greater than 99.9% and a particle size of 50-150 μm and a purity greater than 99.9% and a particle size of 120-200 μm The cobalt-based alloy powder (composition is Co-29Cr-4.4W-1.1Ni-1.1Si-1.1C-0.2Fe, according to the ratio of mass ratio 3:1, put into the mortar, stir evenly for 1h. Weigh 80g and mix The uniform powder is put into a graphite mold, the heating rate is 50°C / min, and the temperature is kept at 1000°C for 20 minutes, the pressure is 30MPa, and the vacuum degree is 8Pa, and discharge plasma sintering is carried out. Austenitic alloy. Its tensile strength at room temperature is 627MPa, and its elongation after fracture is 31.75%.

[0030] like image 3 As shown, it shows that the strength of the new austenitic alloy is higher than that of the iron-chromium-nickel alloy, and it has better plasticity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com