High-damping halogen-free pouring sealant and preparation method thereof

A technology of potting glue and high damping, which is applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., to achieve the effect of expanding the application range, prolonging the storage time, and reducing hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

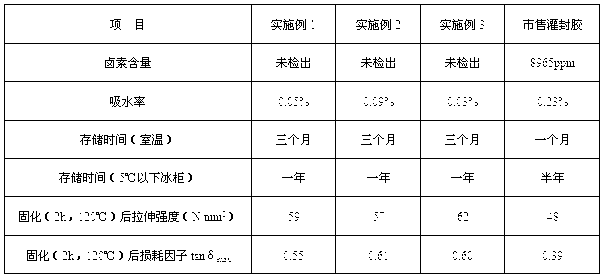

Examples

Embodiment 1

[0023] Example 1: The high-damping halogen-free potting adhesive of the present invention is prepared according to the following steps: (1) Preparation of component A, firstly, 74.4% cyanate ester modified epoxy resin, 3.0% tetraphenol ethane tetra Add glycidyl ether and 0.5% powdered magnesium foam into a vacuum planetary mixer and stir for 60 minutes, where the vacuum degree is 0.080MPa and the speed is 600r / min; then add 15.0% silicon micropowder and 3.5% cyclopolydimethylsiloxane in sequence , 3.5% diphenyldimethoxysilane, 0.1% carbon black, stirred for 120min, wherein the vacuum degree was 0.080MPa, and the rotational speed was 500r / min; component A was obtained. (2) For the preparation of potting glue, mix components according to 100:5 weight percentage of component A and tetraethylenepentamine, and stir in a vacuum planetary mixer for 60 minutes, where the vacuum degree is 0.080MPa and the rotation speed is 300r / min, that is Obtain the high-damping halogen-free potting ...

Embodiment 2

[0024] Example 2: The high-damping halogen-free potting adhesive of the present invention is prepared according to the following steps: (1) Preparation of component A, firstly, 57.4% cyanate ester modified epoxy resin, 12.0% tetraphenol ethane tetra Add glycidyl ether and 4.5% powdered magnesium foam into a vacuum planetary mixer and stir for 60 minutes, where the vacuum degree is 0.080MPa and the rotation speed is 600r / min; then add 25.0% nano silicon powder, 0.3% methyl vinyl cyclosiloxane in sequence Alkane, 0.3% vinyltriethoxysilane, 0.5% titanium dioxide, stirred for 120min, wherein the vacuum degree was 0.080MPa, and the rotation speed was 500r / min; component A was obtained. (2) For the preparation of potting glue, mix components A and tetraethylenepentamine according to the weight percentage of 100:18, and stir in a vacuum planetary mixer for 60 minutes, where the vacuum degree is 0.080MPa and the rotation speed is 300r / min, that is Obtain the high-damping halogen-free ...

Embodiment 3

[0025] Example 3: The high-damping halogen-free potting adhesive of the present invention is prepared according to the following steps: (1) Preparation of component A, firstly, 65.2% cyanate ester modified epoxy resin, 8.0% pentaerythritol glycidyl ether and 2.5% %Powdered foamed magnesium was added to a vacuum planetary mixer, and stirred for 60min, wherein the vacuum degree was 0.080MPa, and the rotating speed was 600r / min; then 20.0% nanometer silicon carbide, 2.0% cyclodimethylsiloxane, 2.0% N- (β-aminoethyl)-γ-aminopropyltrimethyl(ethyl)oxysilane, 0.3% carbon black, stirred for 120min, wherein the vacuum degree was 0.080MPa, and the rotational speed was 500r / min; component A was obtained. (2) For the preparation of potting glue, mix components A and tetraethylenepentamine according to the weight percentage of 100:11, and stir in a vacuum planetary mixer for 60 minutes, where the vacuum degree is 0.080MPa and the rotation speed is 300r / min, that is Obtain the high-damping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com