A kind of high strength and toughness rare earth magnesium alloy and its processing method

A rare earth magnesium and alloy technology, applied in the field of metal heat treatment and magnesium alloy heat treatment, can solve the problems of inability to improve alloy strength, performance not optimal, complicated process, etc., achieve large industrial practical value, improve segregation phenomenon, and increase solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

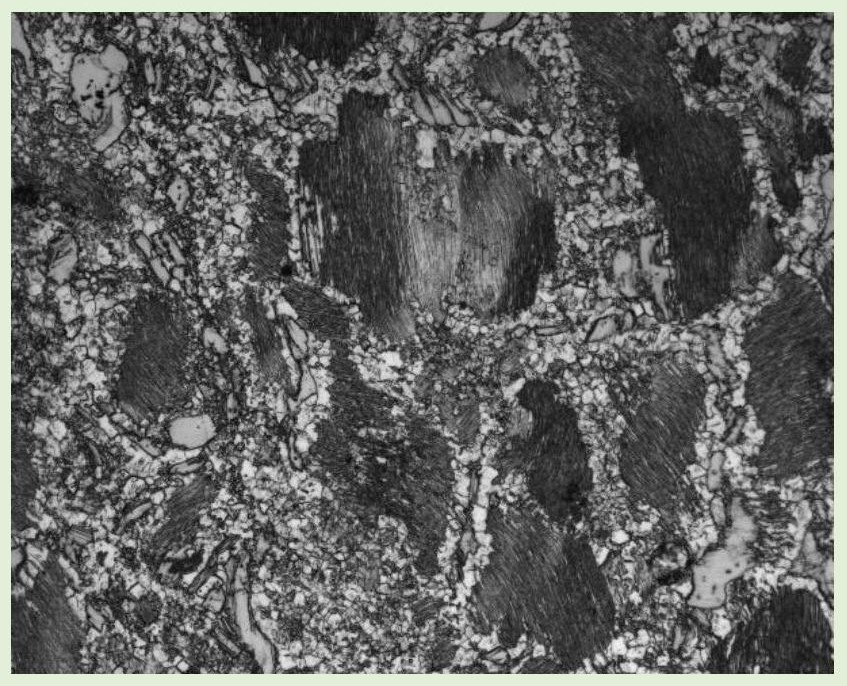

[0092] The material used in this embodiment is a cast Mg-9Gd-4Y-2Zn-0.5Zr (wt.%) rare earth magnesium alloy bar stock with a diameter of 440 mm and a height of 660 mm.

[0093] The present invention adopts a heat treatment method of multi-step aging and annealing, including the following specific steps:

[0094] Step 1, blanking: add a billet with a diameter of 60mm and a height of 50mm from an as-cast bar with a diameter of 440mm and a height of 660mm;

[0095] Step 2. Homogenization treatment: Homogenize the as-cast bar at a temperature of 520°C for 24 hours, then take out the billet and cool it with water at 25°C;

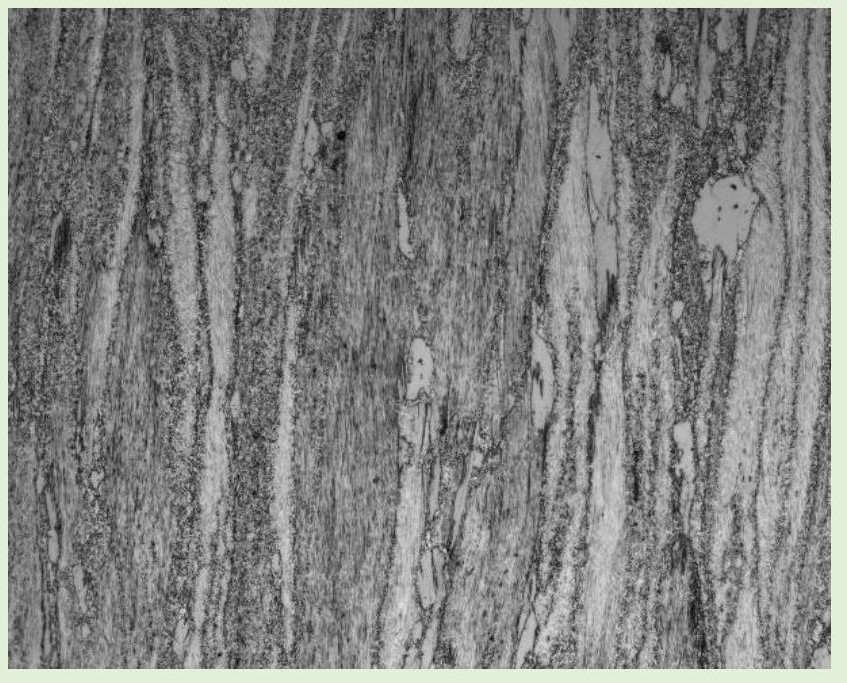

[0096] Step 3. Extrusion deformation: preheat the homogenized billet at 450°C for 30 minutes and put it into an extrusion die that has been preheated at 459°C for 8 hours for extrusion deformation. The extrusion deformation temperature is 450°C. The ratio is 16:1, and the extrusion rate is 0.8mm / s;

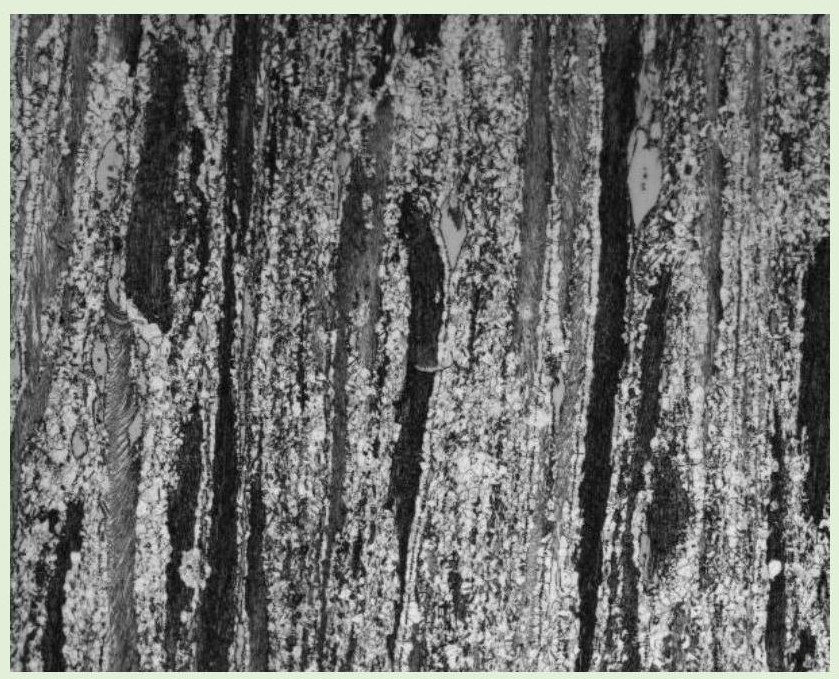

[0097] Step 4, the first aging treatment: Put the extruded b...

Embodiment 2

[0103] The steps are the same as in Example 1, except that the annealing time is 10 h, the yield strength is 400 MPa, the tensile strength is 478 MPa, and the elongation is 10.5%.

Embodiment 3

[0105] The steps are the same as in Example 1, except that the annealing temperature is 400°C. Its yield strength is 412MPa, tensile strength is 485MPa, and elongation is 9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com