Mold Repair Method Based on Laser Cladding Technology

A technology of laser cladding and repairing methods, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., to achieve the effect of repairing skin texture, excellent highlight effect, eliminating color difference and performance difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

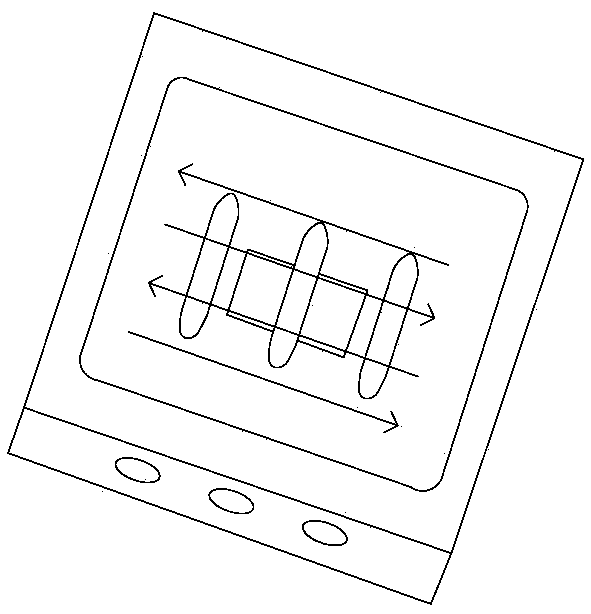

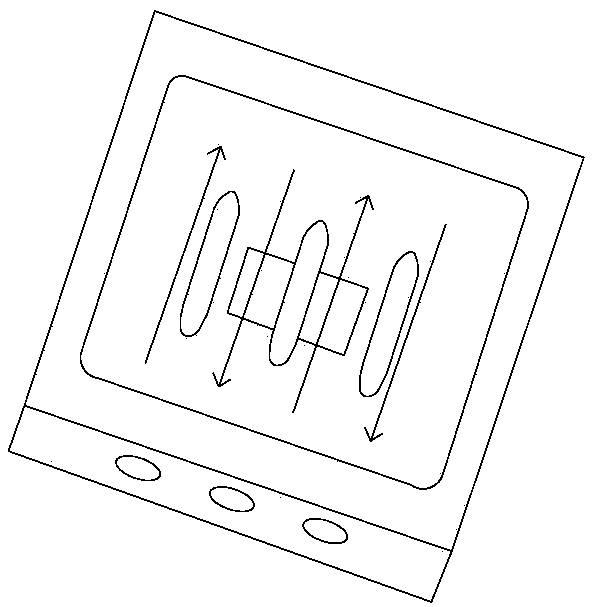

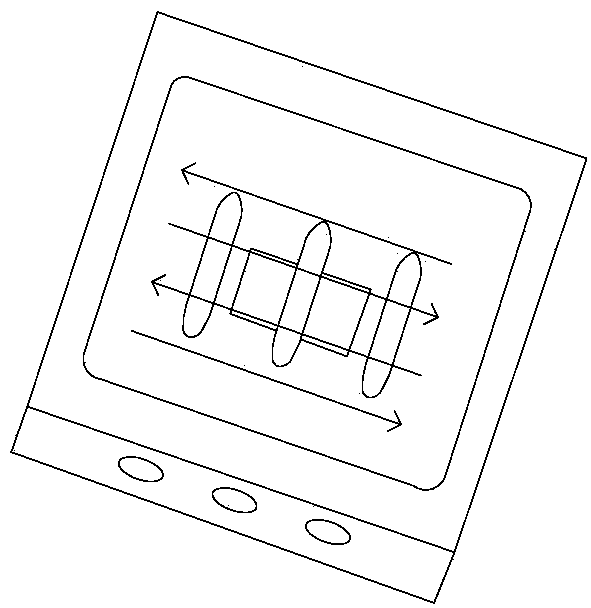

Image

Examples

Embodiment 1

[0044] This embodiment takes 2738 mold steel material as implementation object:

[0045] In the first step, the bevel is processed by mechanical processing, and the angle of the bevel surface is 45°. In order to facilitate laser scanning, all the waterways below the repair are removed.

[0046] The second step is to clean it with alcohol, and preheat the mold at 120°C until the temperature is uniform.

[0047] The third step is to use metal powder made of 2738 mold steel for laser cladding repair under the protection of argon gas. The scanning width is 2.3mm, and the width of the overlapping area of cladding scanning is 0.1mm; after the first layer of laser cladding repair is completed, Stop feeding the metal powder, use the laser to remelt and scan the cladding layer according to the scanning path during cladding repair, and then remelt and scan along the junction of the cladding layer and the mold base. The width of the mold base to be scanned and remelted is 0.5 mm; the ...

Embodiment 2

[0052] Taking the leather pattern mold made of P20 mold steel as the implementation object, the groove is processed at the crack, and the angle of the cut surface is 60°; the mold is cleaned with acetone and preheated at 100°C; the metal powder processed with P20 material is used for Laser cladding, the cladding steps are the same as in Example 1, the difference is that the scanning width is 2.5mm, the width of the cladding overlapping area is 0.08mm, the width of the mold base to be scanned and remelted is 0.8mm, and the cladding layer is higher than the mold Base surface 1.0mm.

[0053] The mold repaired remanufactured parts obtained by the above process have high bonding strength in the repaired area, no defects such as cracks, trachomas, and spatter inclusions. The performance test indicators all meet the requirements, and the repairing engineering precision is high, and the repairing cost is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com