Method for preparing nano fiber composite material containing PMMA (Polymethyl Methacrylate)

A composite material and nanofiber technology, applied in the direction of fiber treatment, fiber chemical characteristics, single-component synthetic polymer rayon, etc., to achieve the effect of large application and industrialization value, high mechanical strength and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Dry 7g of nano-PMMA at 70°C for 2h, add it to 70g of DMAc solvent, and stir evenly for 4h under airtight conditions at 60°C to fully dissolve it to obtain a PMMA solution with a concentration of 10wt%.

[0034] 2) Add 3g of PVDF, stir at room temperature for 0.5h to fully dissolve, and obtain a nano-PMMA / PVDF solution with a mass ratio of 7:3;

[0035] 3) Take 10 mL ethanol solution and add 0.0075 g nano-SiO 2 Particles, ultrasonic vibration for 1h;

[0036] 4) The dispersed nano-SiO 2 Solution is added in the PMMA / PVDF solution, obtains the spinning solution that concentration is 15wt%;

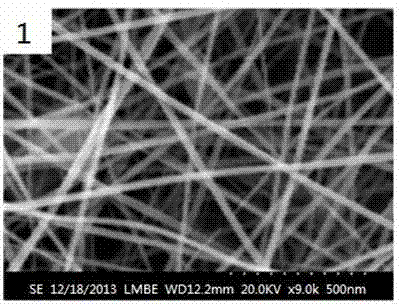

[0037] 5) Uniformly coating the spinning solution on at least one side of the spandex fiber fabric of the structural layer by electrospinning technology to form a nanofiber composite material containing PMMA. figure 1 It is the scanning electron microscope spectrogram of the nanofiber composite material containing PMMA of embodiment 1.

Embodiment 2

[0039] 1) Dry 7g of nano-PMMA at 90°C for 1 hour, then add it to 70g of a solvent with a mass ratio of DMAc / acetone=7:3, and stir evenly for 4 hours under airtight conditions at 60°C to fully dissolve it, and obtain Concentration is the PMMA solution of 10wt%;

[0040] 2) Add 3g of PVF, stir at room temperature for 1 hour to fully dissolve, and obtain a nano-PMMA / PVF solution with a mass ratio of 7:3;

[0041] 3) Take 10 mL ethanol solution and add 0.0075 g nano-SiO 2 Particles, ultrasonic vibration for 1h;

[0042] 4) The dispersed nano-SiO 2 Solution is added in the PMMA / PVF solution, obtains the spinning solution that concentration is 15wt%;

[0043] 5) Uniformly coating the spinning solution on at least one side of the non-woven fabric of the structural layer by electrospinning technology to form a nanofiber composite material containing PMMA.

Embodiment 3

[0045] 1) Dry 9.5g of nano-PMMA at 90°C for 1 hour, then add it to 40g of a solvent with a mass ratio of DMAc / acetone=7:3, and stir evenly at 60°C for 4 hours to fully dissolve it. Obtaining concentration is the PMMA solution of 10wt%;

[0046] 2) Add 0.5g PVDF, stir at room temperature for 1 hour to fully dissolve, and obtain a nano-PMMA / PVDF solution with a mass ratio of 19:1;

[0047] 3) Take 10 mL of ethanol solution and add 0.0075g of nano-Al 2 o 3 Particles, ultrasonic vibration 2h;

[0048] 4) The dispersed nano-Al 2 o 3 Solution is added in the PMMA / PVDF solution, obtains the spinning solution that concentration is 25wt%;

[0049] 5) Uniformly coating the spinning solution on at least one side of the spandex fiber fabric of the structural layer by electrospinning technology to form a nanofiber composite material containing PMMA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com