Track, cleaning system and method for cross-row cleaning of horizontal single-axis tracking system

A technology of tracking system and cleaning system, which is applied in the field of photovoltaic module cleaning, to achieve the effect of convenient and quick on-site installation, reducing impact and saving material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

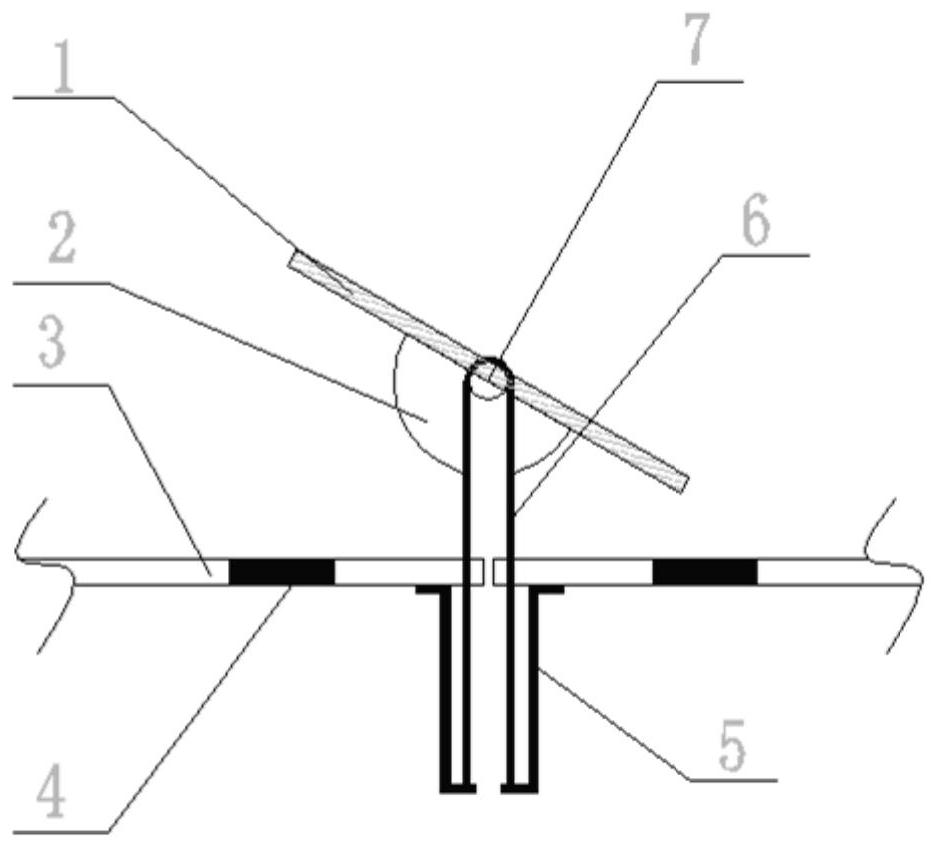

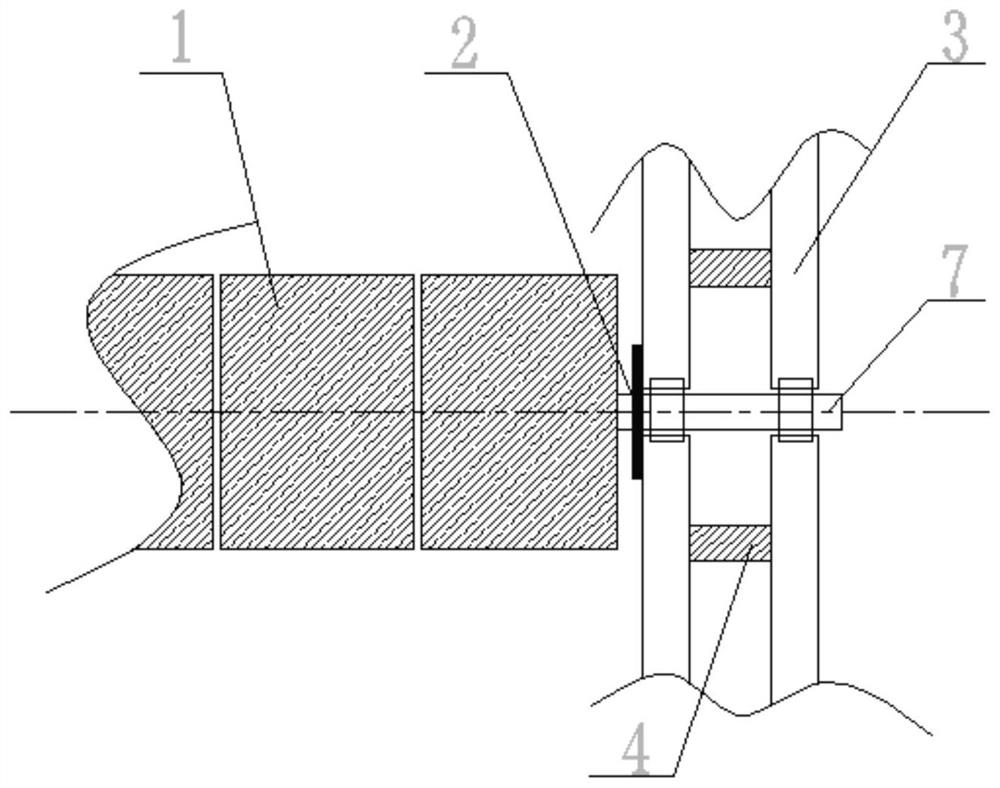

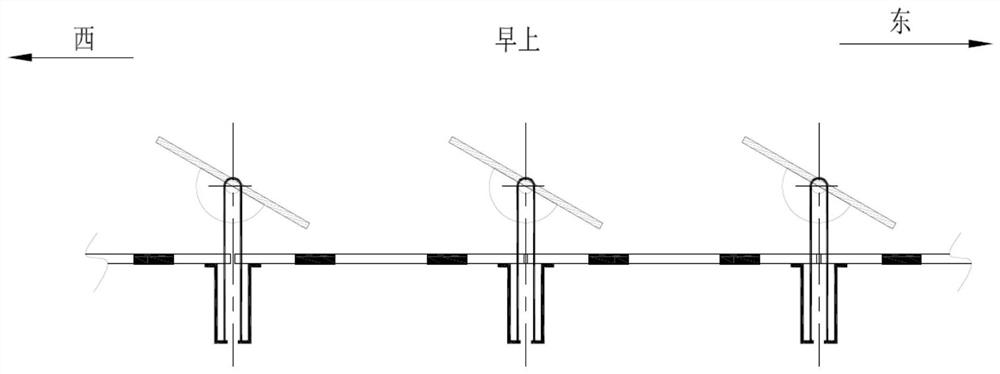

[0040] This embodiment provides a track system for cleaning across rows of a flat single-axis tracking system, and a schematic diagram of a part of its structural units is as follows figure 1 As shown, it includes a flat single-axis tracking system, a rowing track system and a lifting system; the flat single-axis tracking system includes a component and a rotating shaft, the component is installed on the rotating shaft and the component can rotate with the rotating shaft, The over-row track system includes an inter-row track and a transfer table, the transfer table is installed at the end of the inter-row track, and the transfer table corresponds to the position of the assembly.

[0041] The lifting system in this embodiment includes two lifting motion units arranged in parallel, a fixing unit and a separate guiding and limiting device, wherein the upper part of the lifting motion unit is fixed on the rotating shaft of the flat single-axis tracking system, and the lifting motio...

Embodiment 2

[0046] This embodiment provides a method for cleaning using the track system in Embodiment 1, the schematic flow chart of which is as follows Figure 7 shown, including the following steps:

[0047] S1, first rotate the components of the flat single-axis system to a horizontal or slightly inclined state, and the over-row track system reaches the designated position under the action of the lifting system;

[0048] S2, the cleaning robot judges whether the horizontal single-axis tracking system is in the robot cleaning mode, if yes, judges whether the lifting system is self-locked, if yes, starts the cleaning robot, otherwise, restarts the cleaning robot after the aforementioned conditions are met;

[0049] S3, the started cleaning robot runs along the inter-row track to the conversion table at the end of the current row of components;

[0050] S4, the cleaning robot climbs up the corresponding components of the conversion platform along the conversion platform, and starts to c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap