Limited penetration perforating methods for oilfield applications

A technology of perforating bullets and permeability, applied in earthwork drilling, wellbore/well components, explosive charges, etc., can solve problems that are not suitable for effective fluid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

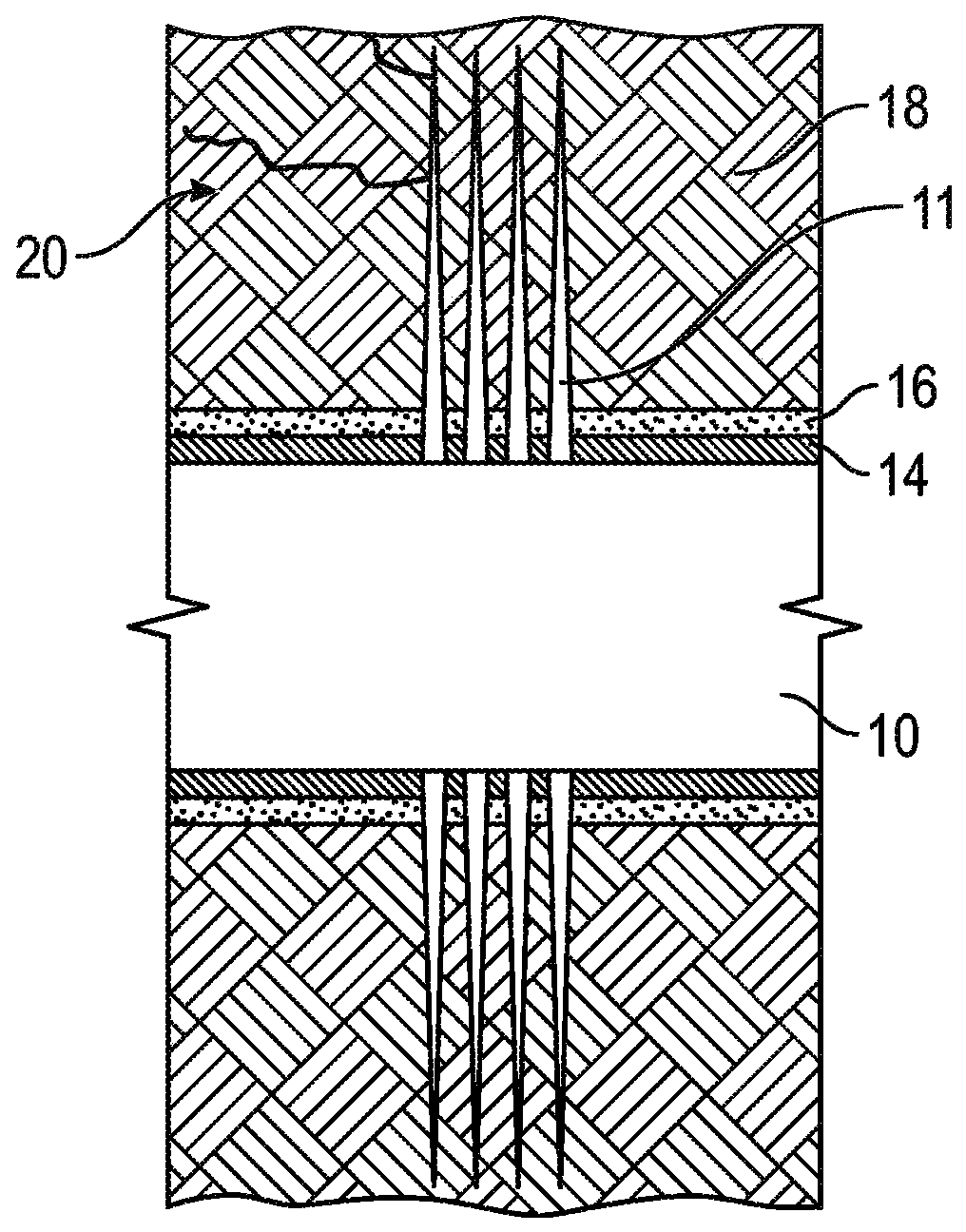

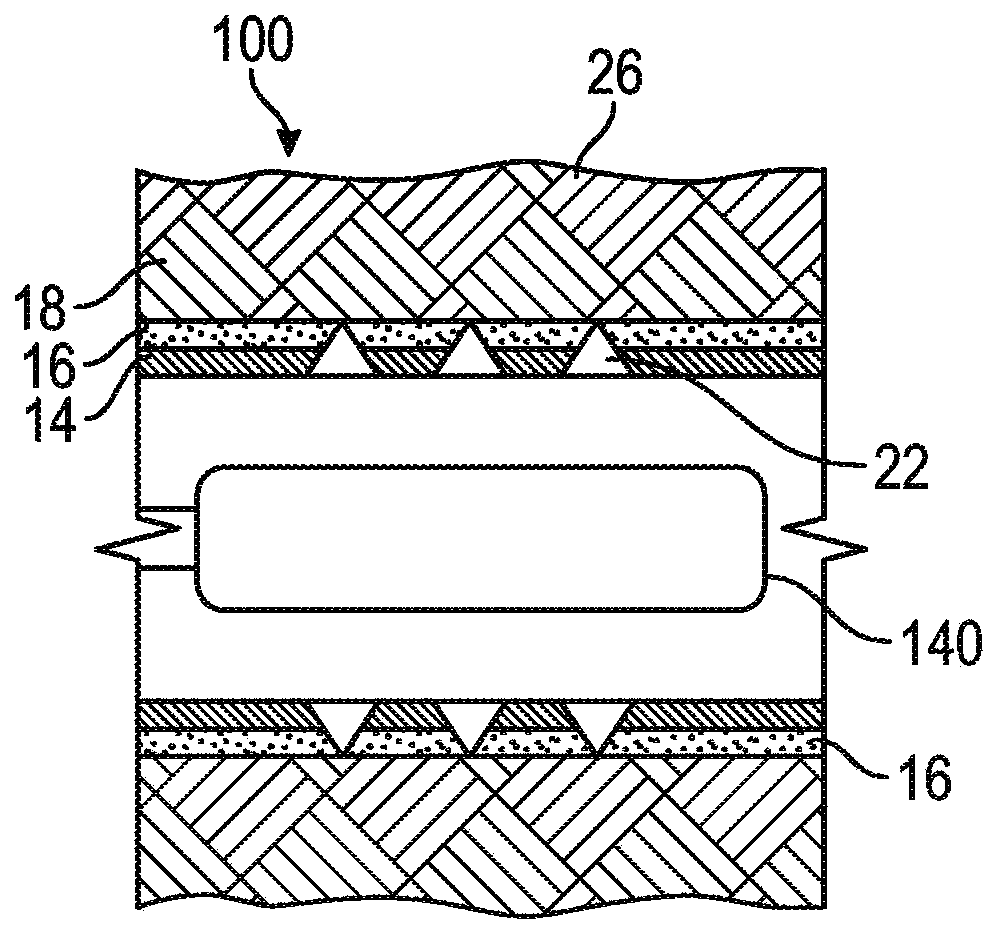

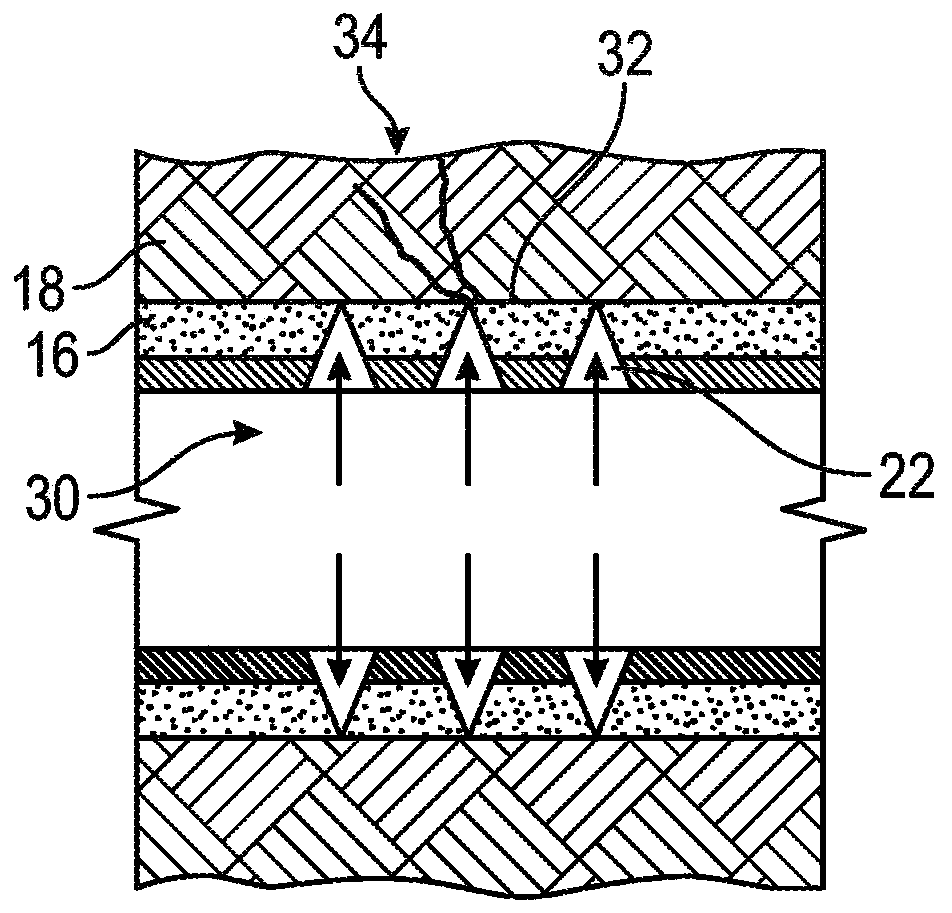

[0015] Aspects of the present disclosure provide methods and related perforating tools for completing wells in unconventional formations, such as hydrocarbon-bearing shale formations. For purposes of this disclosure, an "unconventional" formation is typically a formation with a permeability of less than 10 millidarcy (mD). Many "unconventional" formations have permeability between 1 nanoDarcy (nD) and 1 millidarcy (mD). In contrast to traditional perforating techniques, perforating tools according to the present disclosure are designed to drill holes only in the well tubular and surrounding cement sheath. The rock and soil surrounding the wellbore are at best impacted only by the perforating jets produced by the perforating tools. Thus, bowing and microcracks can be significantly reduced, if not eliminated. Thus, by maintaining the formation layer substantially intact, the effectiveness of subsequent hydraulic fracturing operations may be improved.

[0016] refer to Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com