Fireproof blanket and production method thereof

A production method and technology of fireproof blankets, which are applied in the field of fireproof blankets and their production, can solve the problems of open flames, no fire protection, damage to cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary, and is not intended to limit the scope of the present invention and its application.

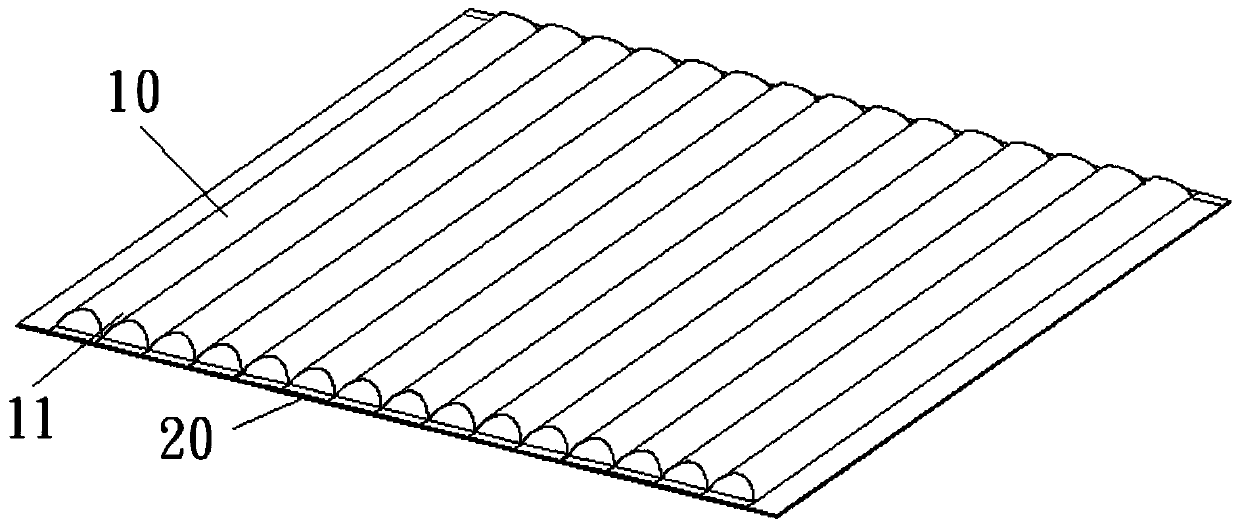

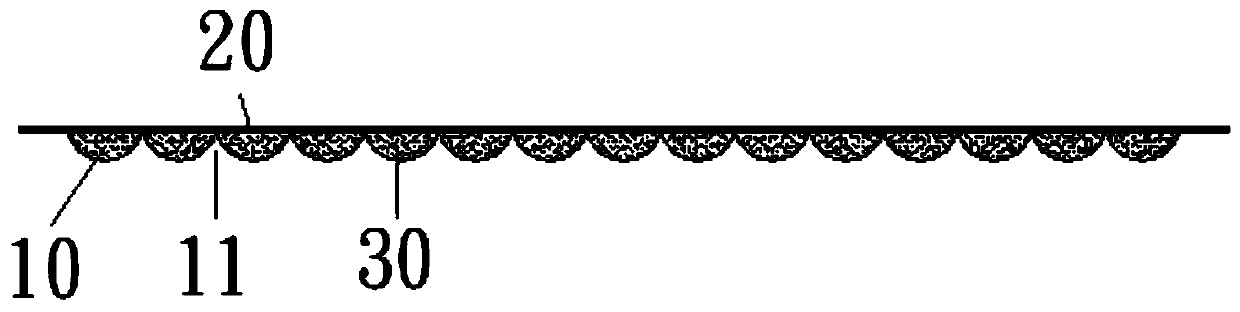

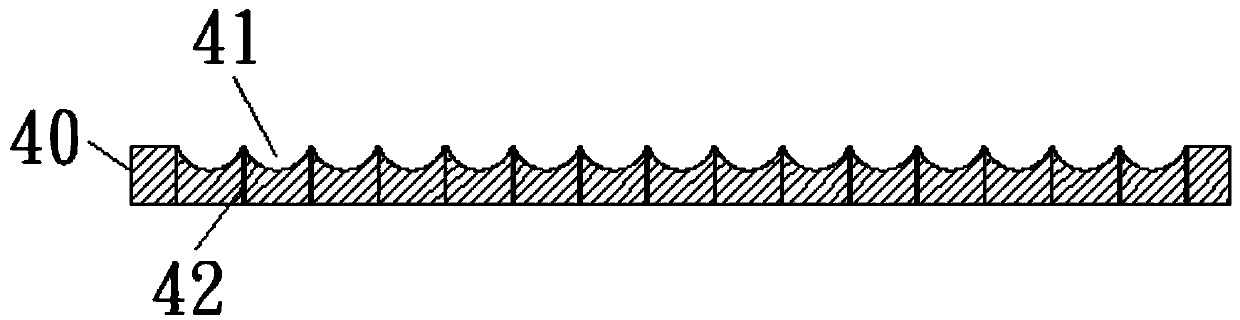

[0033] See figure 1 with figure 2 , The fire blanket of the present invention includes a first bendable cover sheet 10, a second bendable cover sheet 20, and an inorganic heat-absorbing material 30 located between the first bendable cover sheet 10 and the second bendable cover sheet 20 The inorganic heat absorbing material 30 is an inorganic material that absorbs heat and releases water vapor when heated, the first flexible coating sheet 10 is recessed with at least one recessed through hole 11 from the outside to the inside, and the second The flexible covering sheet 20 is in the shape of a flat sheet.

[0034] When the fire blanket of the present invention is applied to cover cable joints, the first bendable coating sheet 10 of the fire b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com