A plastic particle shredder

A technology of plastic particles and discharge port, which is applied in the field of plastic particle breakers, can solve the problems affecting the quality of granulation, and achieve the effect of consistent size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

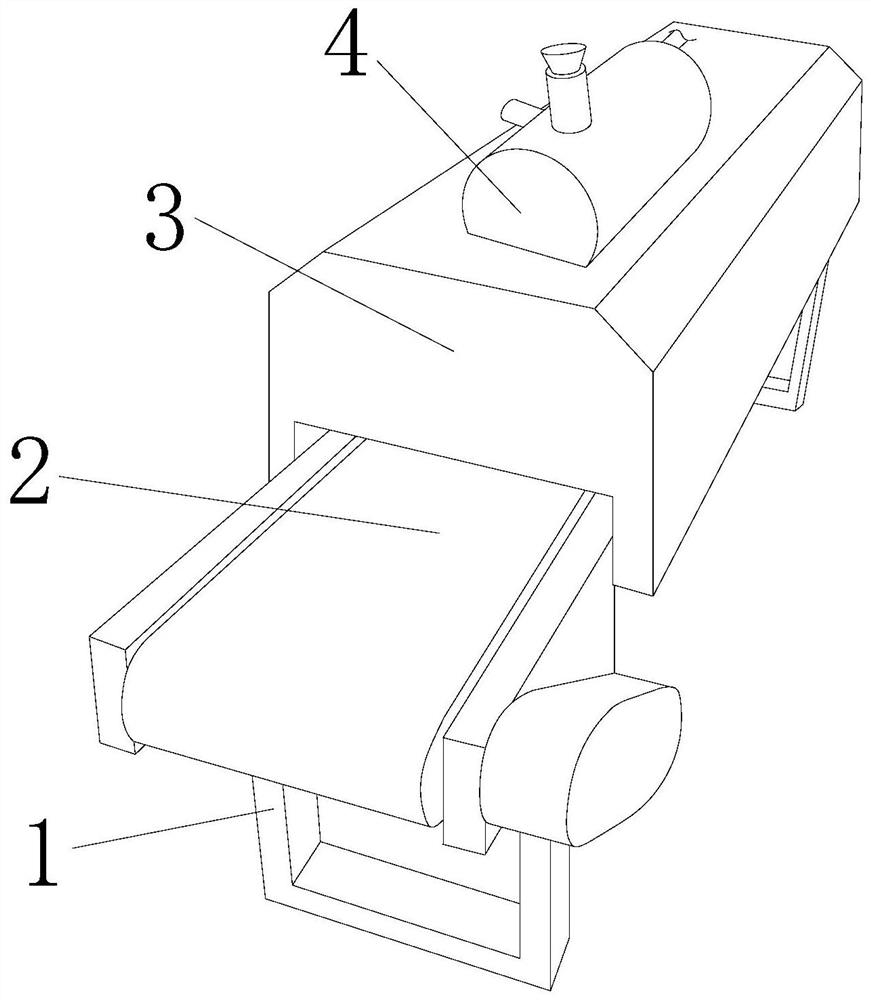

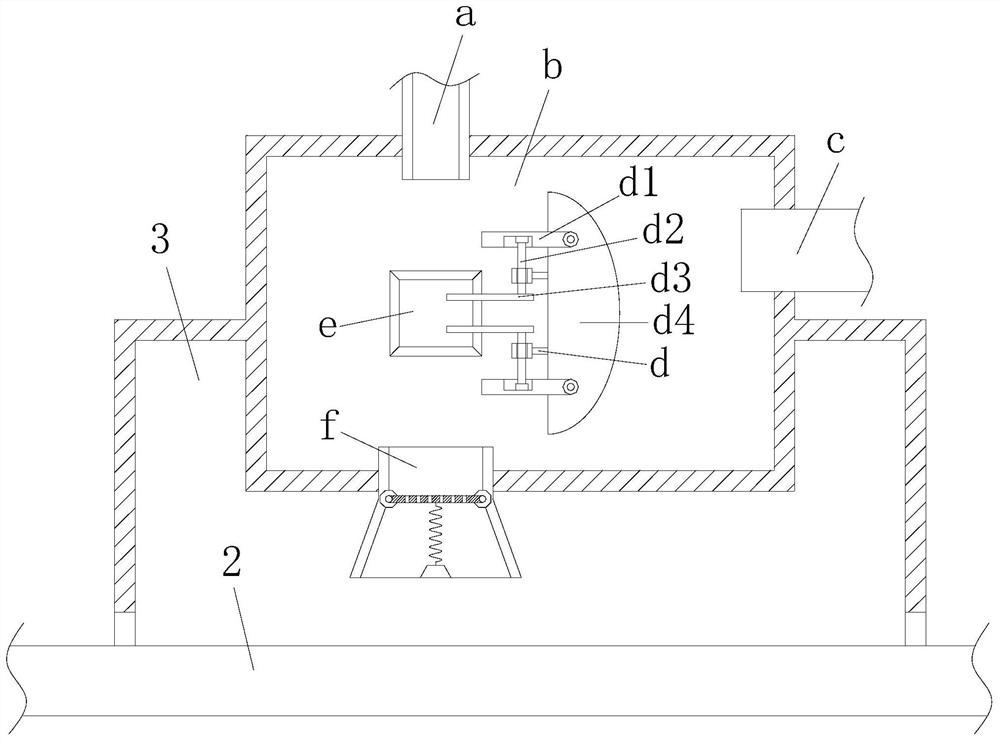

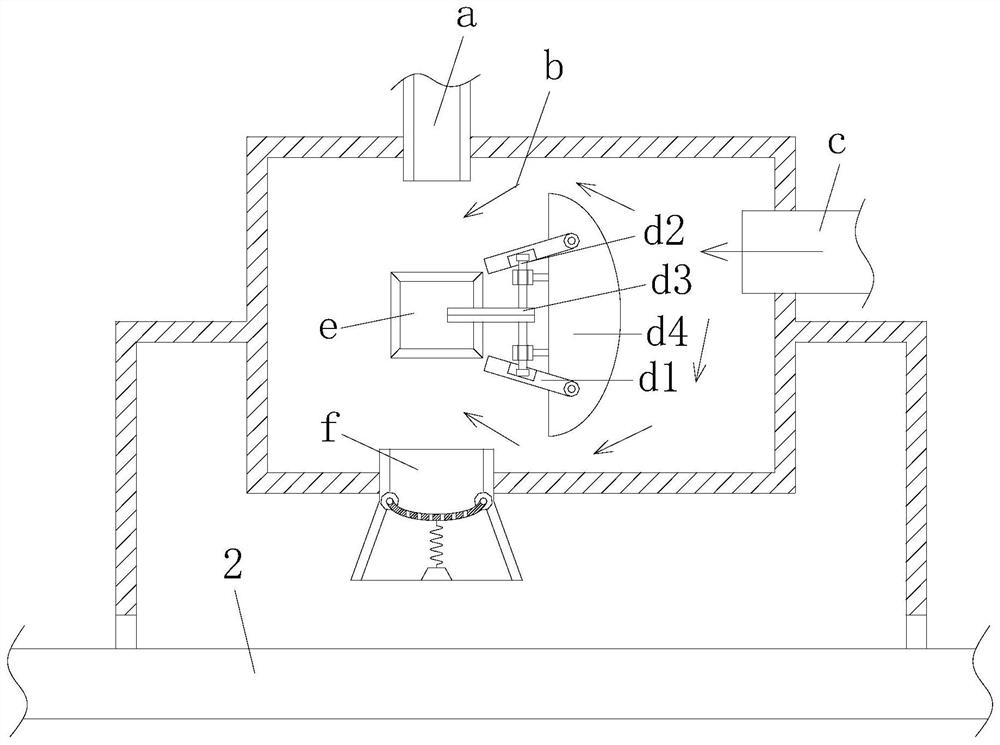

[0024] see Figure 1-Figure 6 , the present invention provides a plastic particle breaker, the structure of which includes a support frame 1, a conveyor belt 2, a cover 3, and a crushing device 4. The support frame 1 is provided with a conveyor belt 2, and the conveyor belt 2 is installed in an embedded form. On the support frame 1, the support frame 1 is connected with the conveyor belt 2, and the conveyor belt 2 is provided with an outer cover 3, and the outer cover 3 is set up in a U-shaped structure, and the outer cover 3 covers part of the conveyor belt 2, and the outer cover 3 3 is connected with the crushing device 4;

[0025] The crushing device 4 is composed of a No. 1 feeding pipe a, a crushing cavity b, an air inlet duct c, a crushing mechanism d, a No. 2 feeding pipe e, and a discharge port f. The No. 1 feeding pipe a It communicates with the crushing chamber b, the crushing chamber b is connected to the discharge port f, the crushing chamber b communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com