Efficient double-area electrostatic oil mist purifier

An electrostatic and purifier technology, which is applied in the field of high-efficiency dual-zone electrostatic oil mist purifiers, can solve the problems of increased cost, large module volume and large footprint, and achieves increased efficiency, increased area, and increased work. The effect of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

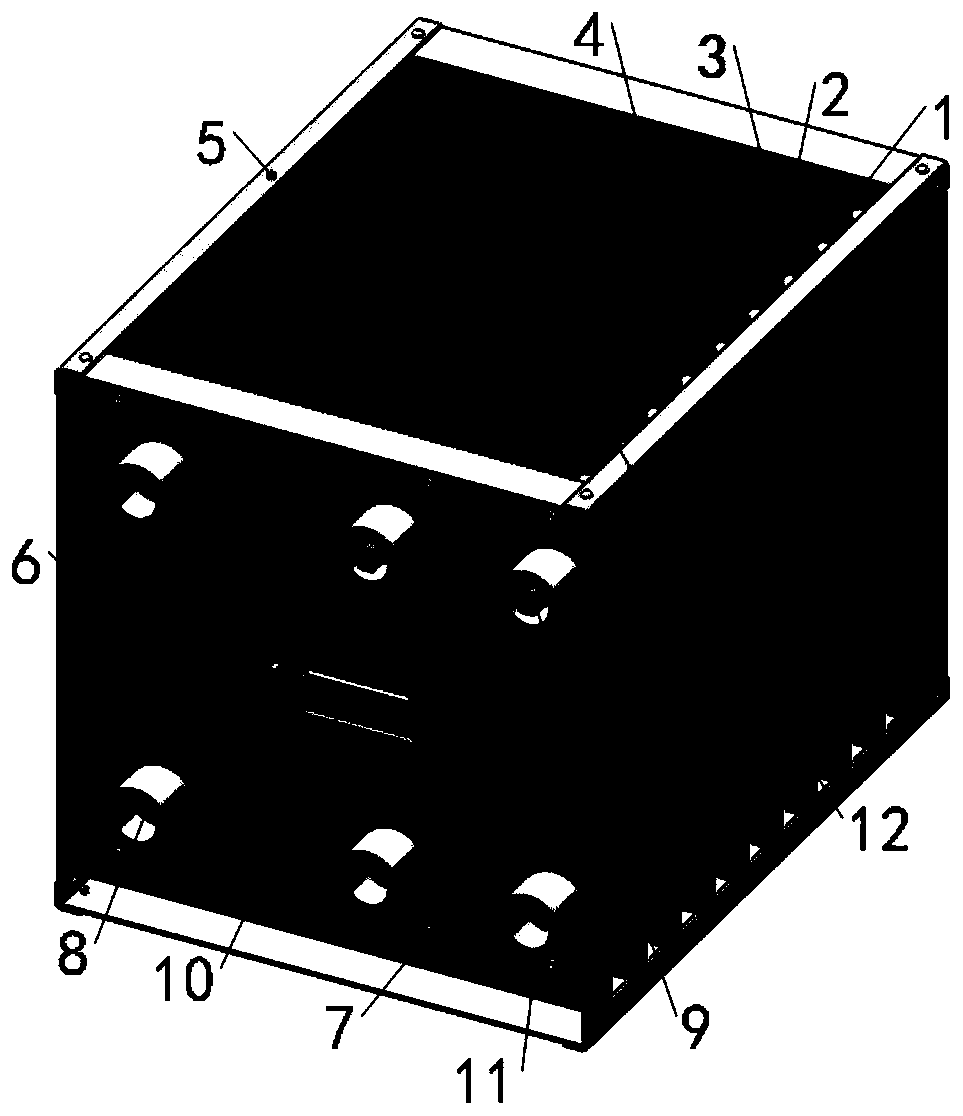

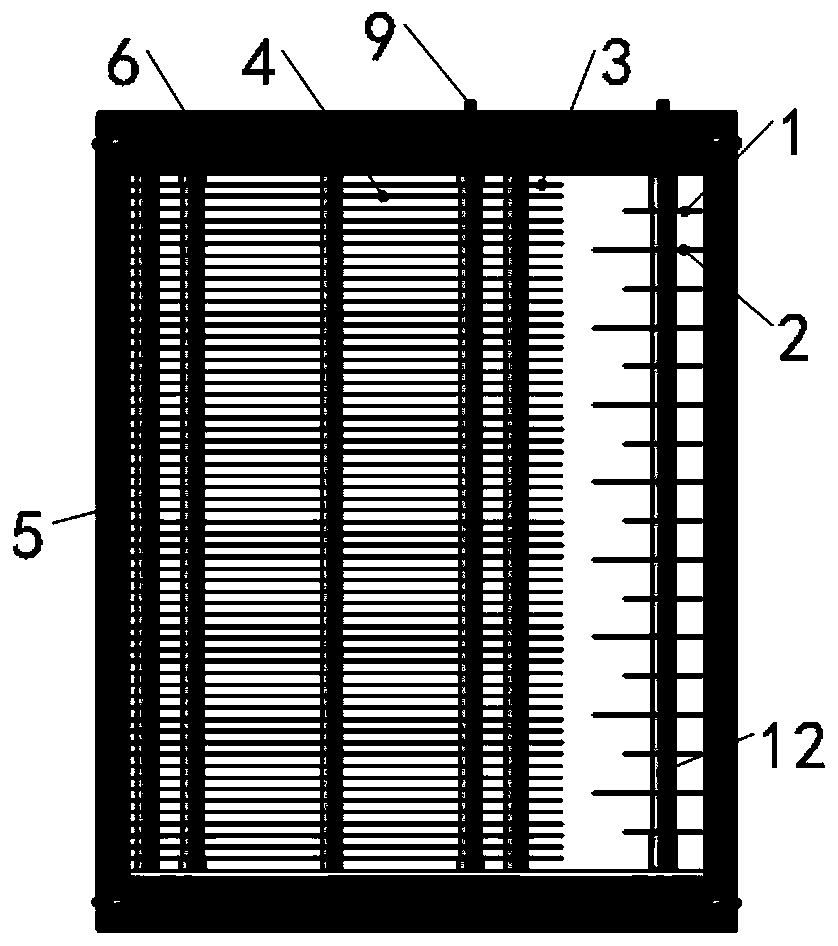

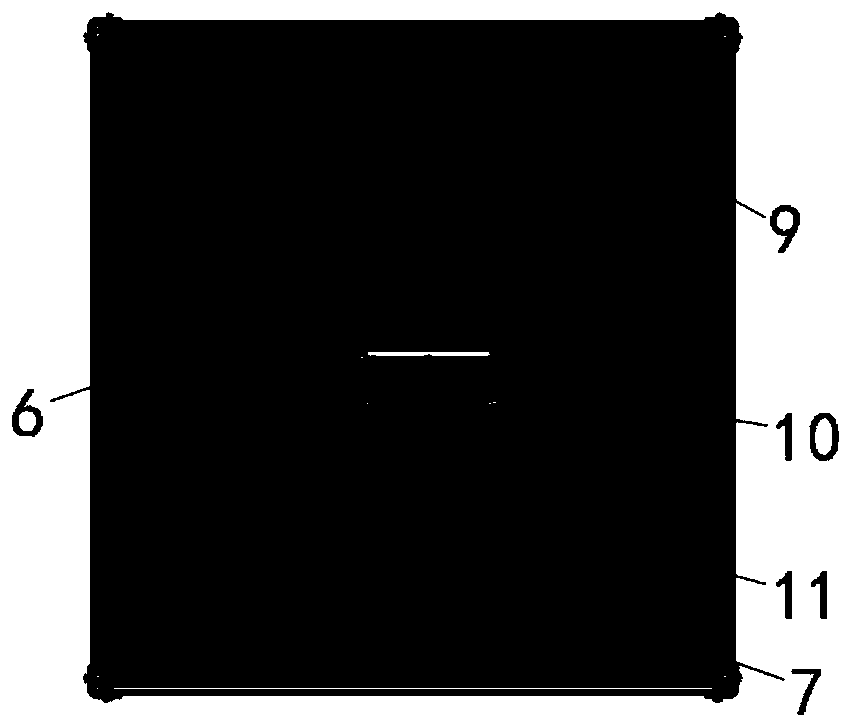

[0039] The module is 530mm wide, 430mm high, and 410mm long. The length direction is the direction of airflow movement, that is, the direction from the charging area to the dust collection area. A high voltage of -12kV is applied to the charging area, and a high voltage of -8kV is applied to the dust collection area. The distance between the burr in the charging area and the adjacent grounding plate is 24mm, and the distance between the high voltage plate and the grounding plate in the dust collection area is 7mm.

[0040] The burr in the charging area is 50mm long and 400mm wide, and the distance between adjacent discharge tips is 30mm, made of 1mm thick 304 stainless steel; the grounding plate in the charging area is 90mm long and 420mm wide, made of 1mm thick 7075 aviation aluminum material. The hole diameter of the overvoltage fixing rod in all charging area thorns and grounding plates is 16mm, and the hole diameter of the grounding fixing rod is 6.5mm.

[0041] The high-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap