Filter element water-stop assembly, filter element device and water purifier

A water-stop and component technology, used in valve devices, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of complicated disassembly and assembly operations, increased assembly difficulty, water leakage, etc., to achieve a good control feel, reduce Frustration, the effect of simplifying the assembly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

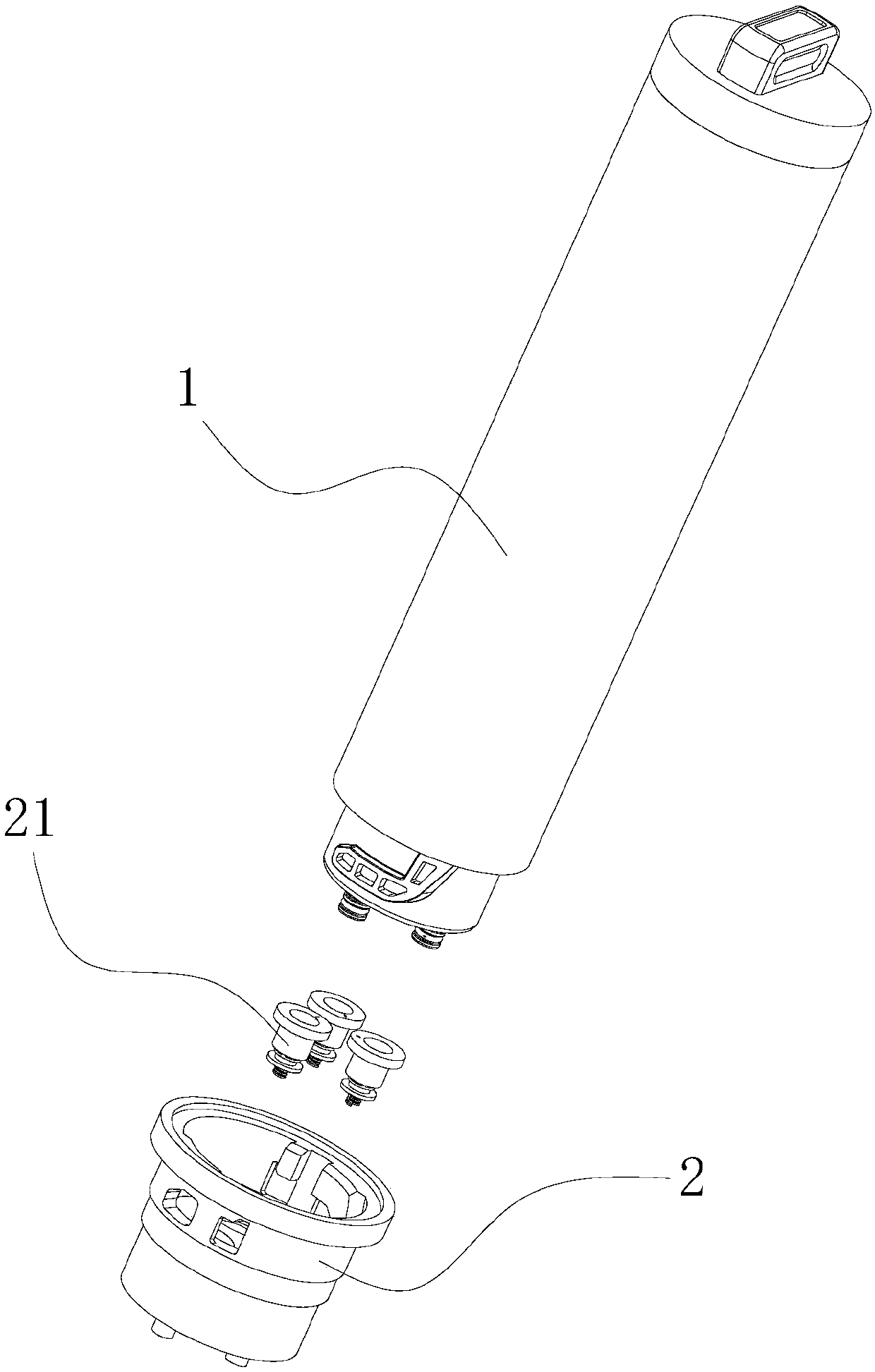

[0064] Such as figure 1 As shown, the embodiment of the present invention provides a filter element device, which mainly includes a filter element body 1 and a base 2, the base 2 is provided with a base flow channel connected with an external flow channel, the filter element body 1 is provided with a body flow channel, and the filter element body 1 The first end is screwed into the base 2 and the flow channel of the main body is aligned with the flow channel of the base. There is an automatic water locking component 21 between the main body flow channel and the base flow channel. The filter body 1 and the base 2 control the automatic water locking component through relative rotation 21 is opened and closed to realize the connection and disconnection of the main body flow channel and the base flow channel.

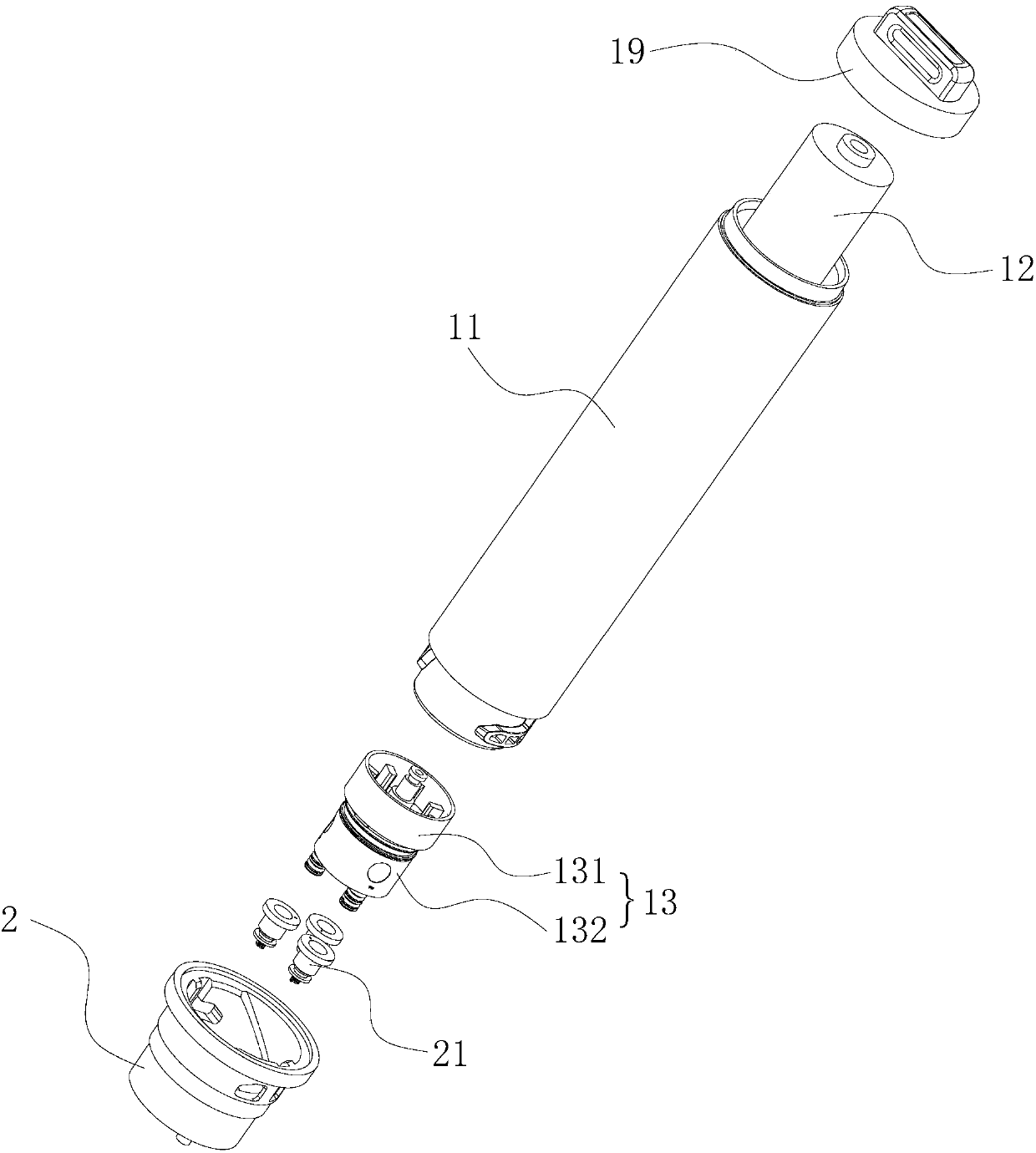

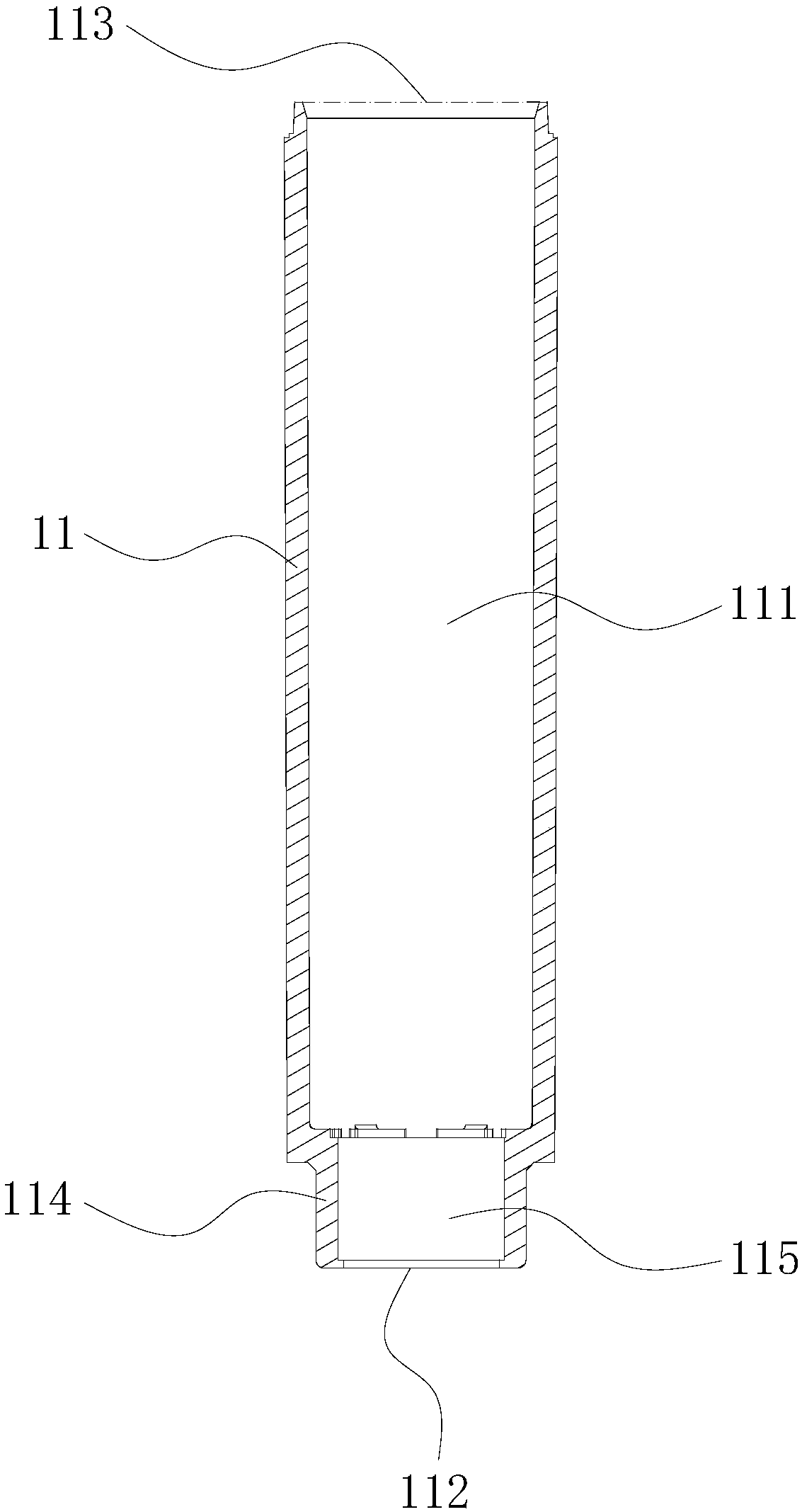

[0065] Specifically, such as Figure 2 to Figure 4 As shown, the filter element body 1 includes a housing 11, a filter material 12 and a water-stop assembly 13. The housin...

Embodiment 2

[0078] Such as Figures 17 to 19As shown, the only difference between this embodiment and Embodiment 1 is that the filter element device in this embodiment adopts a double-channel structure, that is, it includes an inlet channel for accessing tap water and an outlet channel for discharging filtered water. , there is no sewage discharge flow channel for discharging filtered waste water, therefore, the first water inlet flow channel 14a is formed between the inner side wall of the housing 11 and the outer side wall of the filter material 12, and the flow channel cavity of the filter material 12 is the first outlet. The water channel 14b; the water channel in the water channel 131 includes a second water inlet channel 15a and a second water outlet channel 15b, which are combined into an inner cavity that runs through the rotating shaft 1311, the connecting column 1312 and the first limiting column 1316, and The second water inlet channel interface 151 and the second water outlet ...

Embodiment 3

[0080] Such as Figures 20 to 22 As shown, the difference between this embodiment and Embodiment 1 is that there is no sealing disk 1313 between the rotating shaft 1311 of the water distribution member 131 and the connecting column 1312 in this embodiment, instead, a partition is provided in the installation cavity 111. The dividing plate 116 of the water-distributing member 131 and the water-retaining member 132, the center of the dividing plate 116 is provided with a through hole, and the rotating shaft 1311 of the water-distributing member 131 passes through the through hole and is rotatably connected with the rotating hole and rotating hole 1321 of the water-retaining member 132; and , the first protrusion 171 is disposed on the partition plate 116 , and the first protrusion 171 and the first sliding groove 172 of the water retaining member 132 form a sliding limit structure. Of course, the first protrusion 171 of the partition 116 and the first sliding groove 172 of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com