Construction method of inclined throwing support protector and inclined throwing support protector

A construction method and technology of oblique throwing, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems of destructive impact and high risk of enclosure walls, and achieve the advantages of easy demolition and recycling, reduced production costs, fast and safe construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

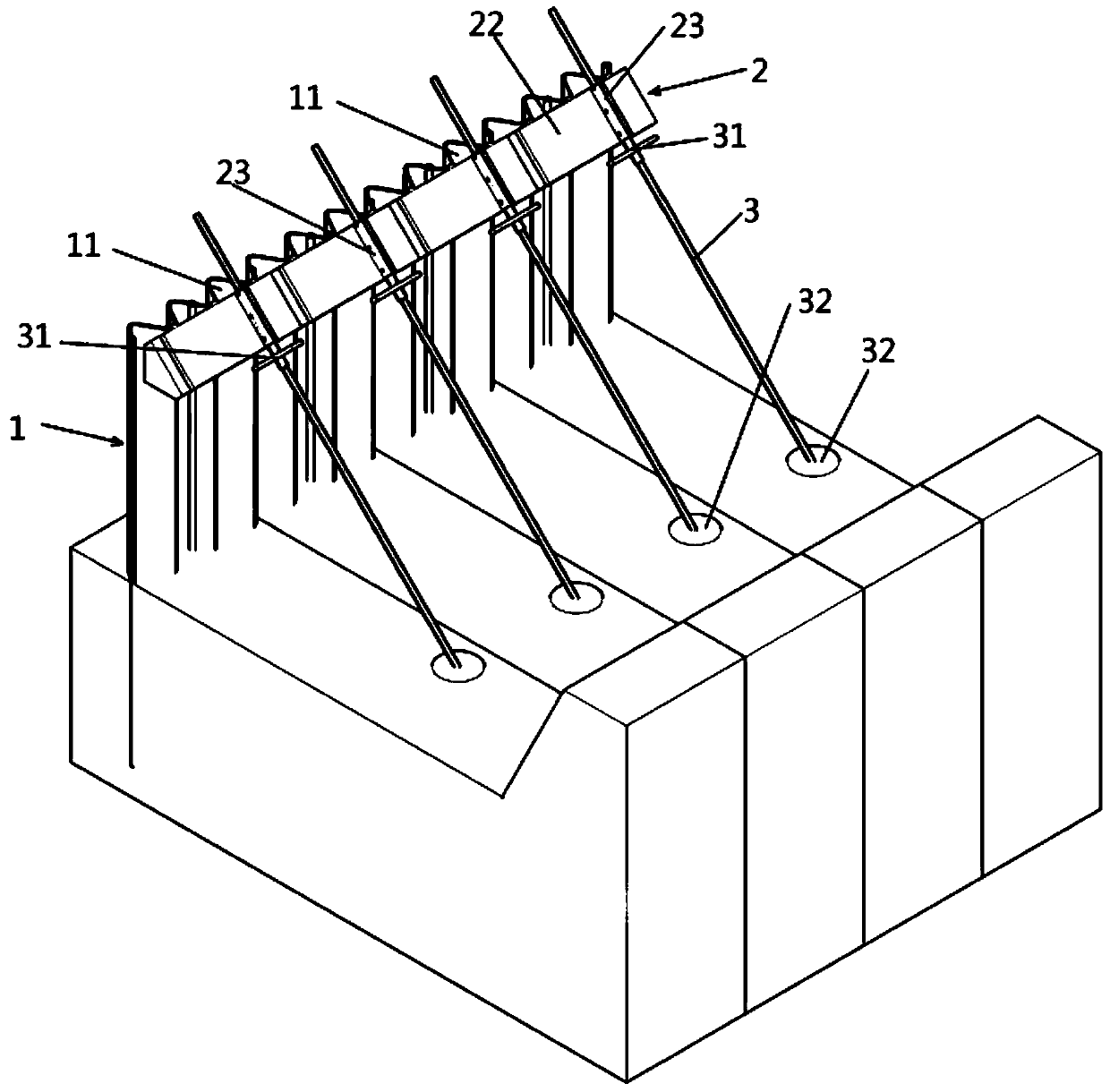

[0037] Embodiment 1, a construction method of oblique throw support, comprising:

[0038] Step 1, fixing the purlin structure 2 along the upper edge of the retaining wall 1, and the length of the purlin structure 2 extends along the extending direction of the retaining wall 1;

[0039] Step 2: Install the oblique brace 3 obliquely on the same side on the purlin structure 2, and form a guide channel 21 on the purlin structure 2 that allows the oblique brace 3 to move along the only linear direction, allowing the oblique brace 3 to move along its length direction Moving relative to the purlin structure 2, a right angle a or an acute angle a is formed between the diagonal brace 3 and the retaining wall 1, and the right angle a can correspond to a slope bank with a relatively steep angle, that is, the diagonal brace 3 is horizontally braced on the slope bank; the acute angle a can correspond to a relatively gentle slope bank or flat ground, such as the inclined throw support 3 alo...

Embodiment 2

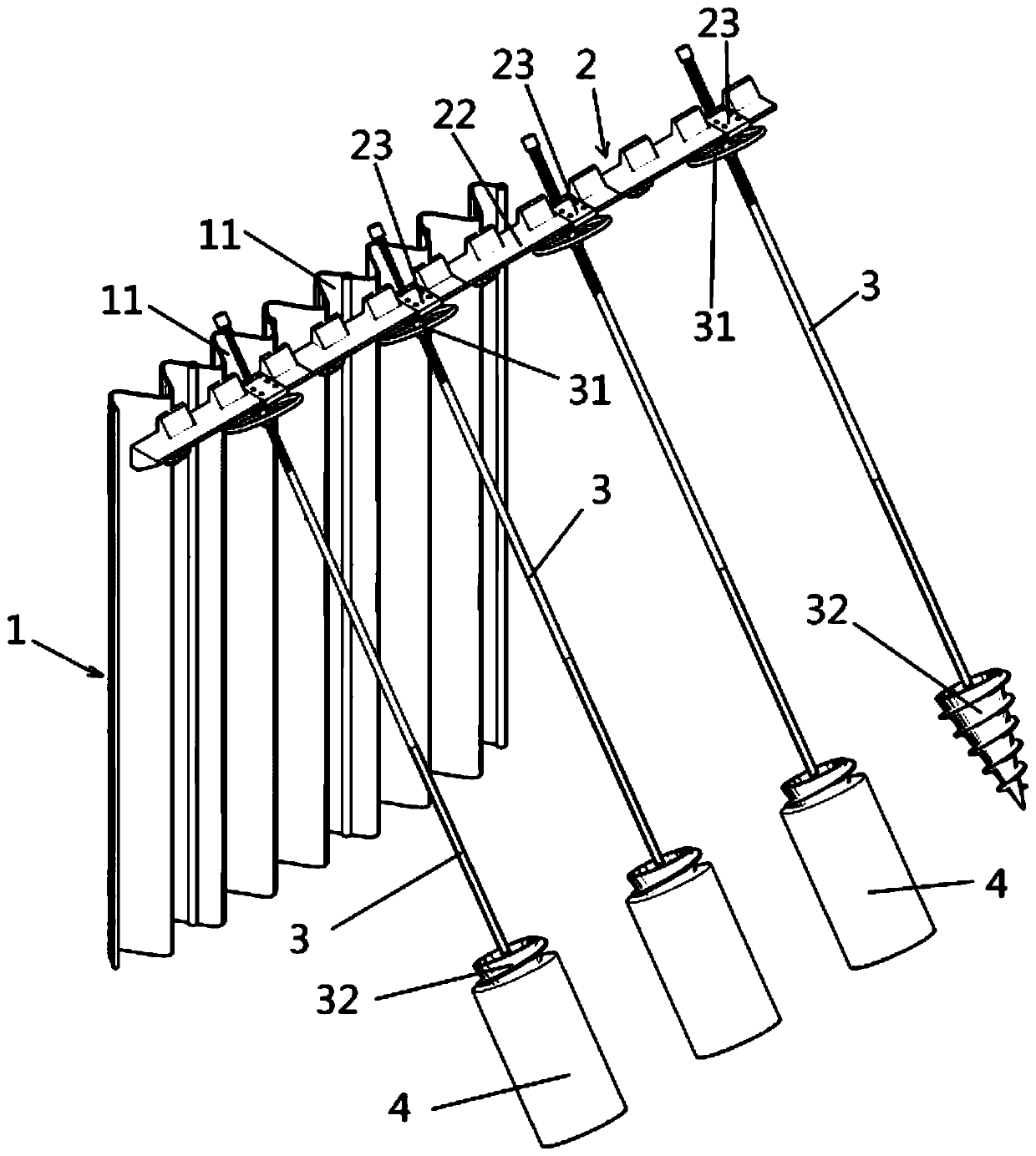

[0049] Embodiment two, as attached figure 2 As shown, the main difference between the second embodiment and the first embodiment is that the structure of the diagonal support leg 32 is different. Tapping legs, pointed self-tapping legs have self-tapping threads that can be easily drilled into the soil when rotating, that is, the diagonal throwing brace 3 is inserted or screwed into the soil relative to the purlin structure 2 along its length direction. The threaded fit between the oblique brace 3 and the purlin structure 2 is similar to the use of the screw-in type to move the oblique brace 3 up and down. Similarly, if the soil is loose, it can be done before the oblique brace 3 enters the soil, and after entering the soil It is also possible to use a cement high-pressure rotary grouting machine to pour concrete or cement slurry into the soil corresponding to the slanting support feet 32 to form the pier 4, so that the pointed self-tapping support feet and the pier 4 thread...

Embodiment 3

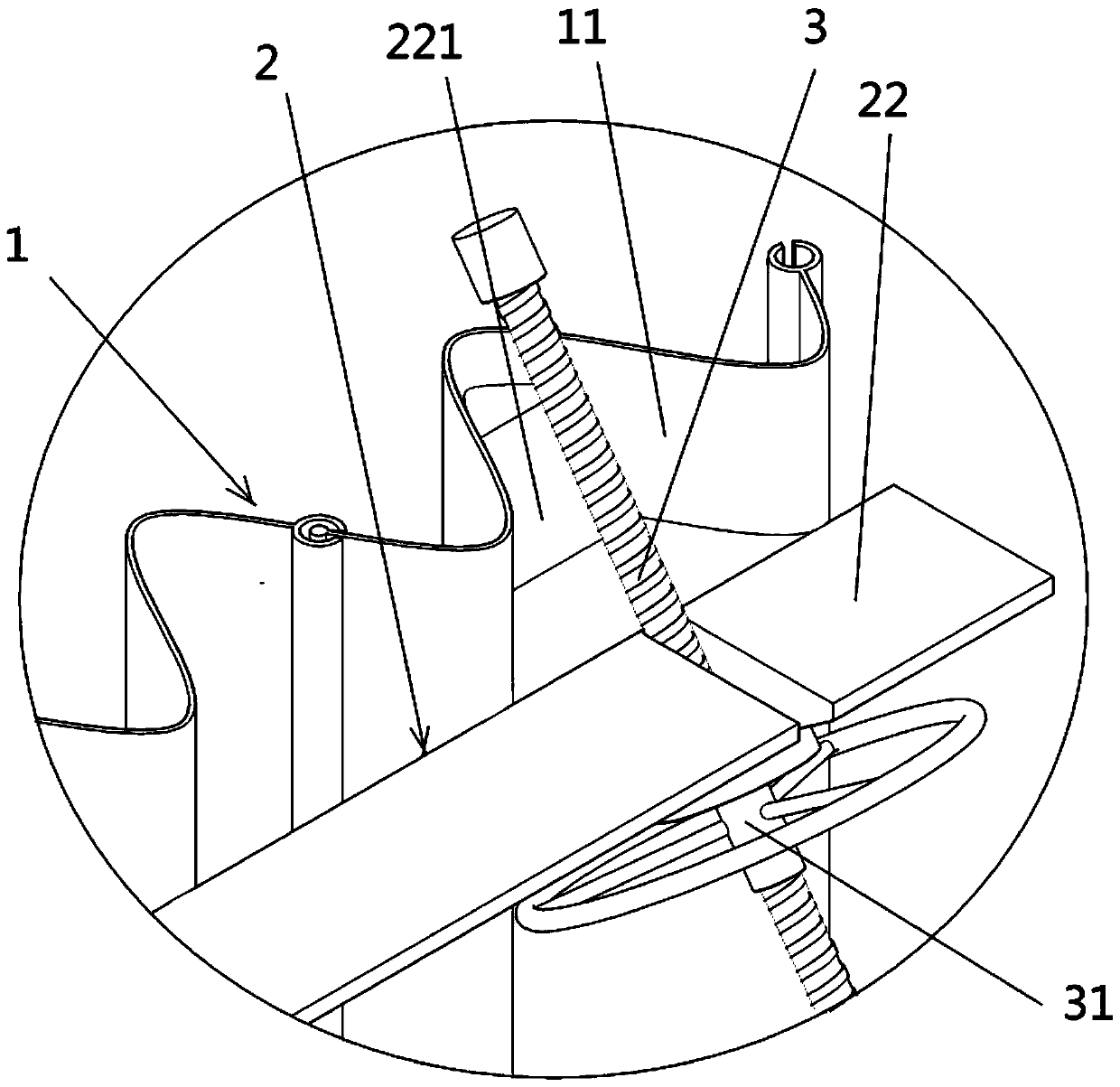

[0050] Embodiment three, as attached image 3 As shown, the difference between Embodiment 3 and Embodiments 1 and 2 is that the purlin body 22 has a protruding purlin reinforcement part 221, and when the purlin structure 2 is fixed along the upper side of the enclosure wall 1, the purlin reinforcement is fixed. part 221 , the purlin reinforcement part 221 is inserted into the groove 11 and fixedly connected with the enclosure wall 1 . Further, the installation between the purlin structure 2 and the retaining wall 1 is firm and stable. The purlin body 22 is provided with a groove for accommodating the oblique throwing brace 3, rather than a guiding channel with the only direction. Diagonal cast support 3 can be removed and inserted in the groove. However, due to the conflict between the limit lock 31 and the purlin body 22 and the pressure from the outside of the retaining wall 1 , the diagonal throw brace 3 can be stably inserted in the groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com