Motor-driven complementary double-wheel foam bar releasing device

A technology of motor-driven and feeding devices, which is applied in wellbore/well components, mining fluids, earthwork drilling and mining, etc. It can solve problems such as high labor intensity, slow drop of foam row rods, and potential safety hazards for operators, and achieve simple transmission , easy installation, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

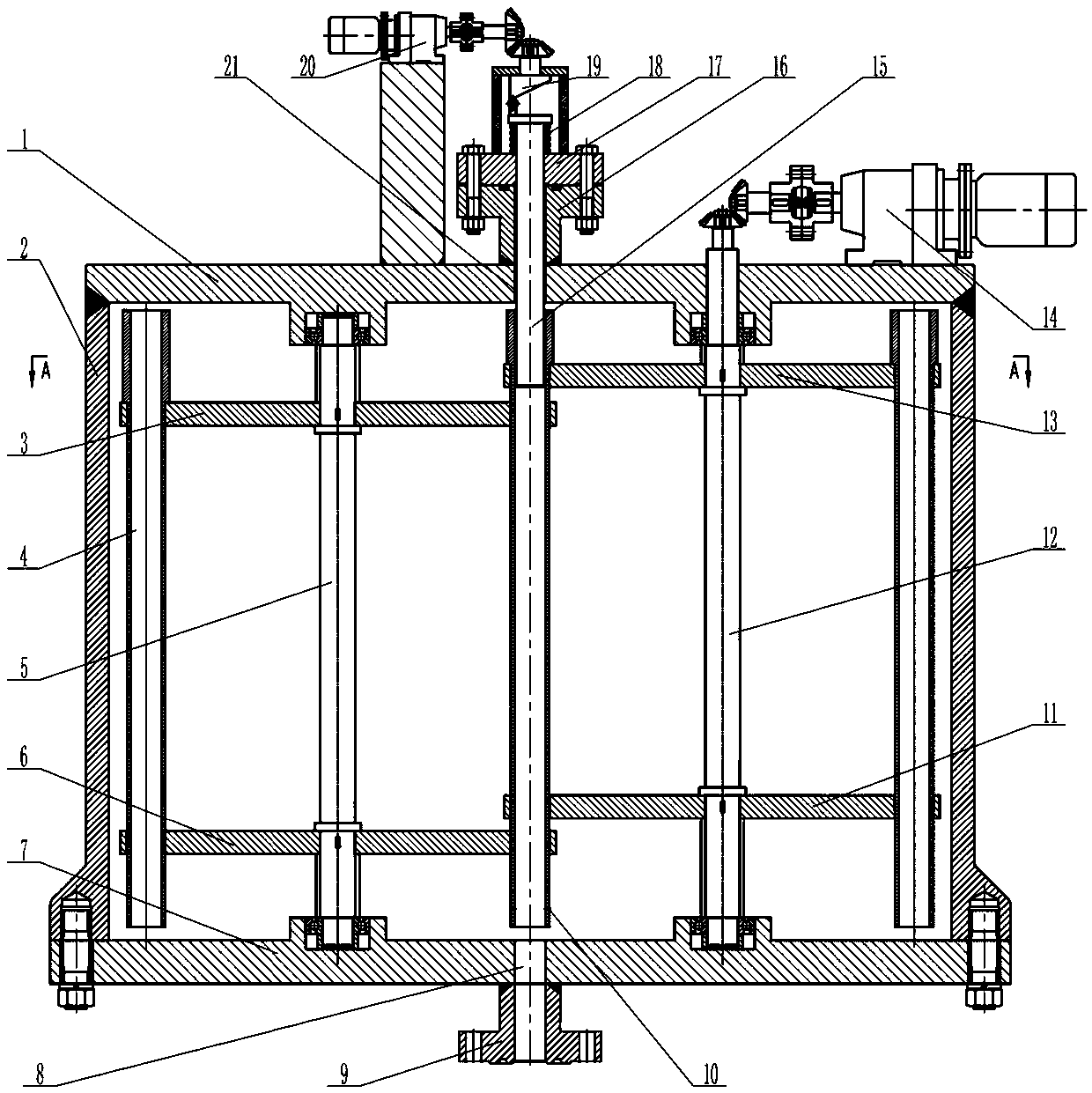

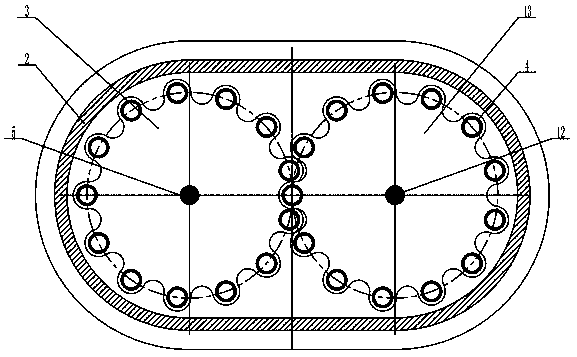

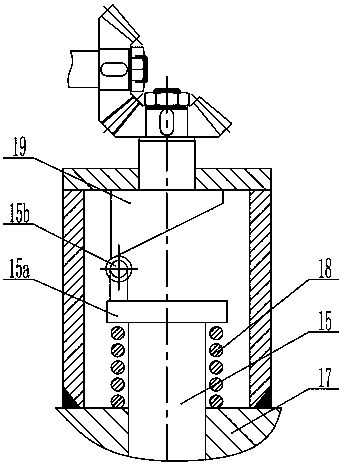

[0019] Such as Figure 1~3 As shown in the figure, a motor-driven complementary double-wheel foam row rod delivery device consists of an upper cover plate 1, a housing 2, a driven upper dial 3, a charging cylinder 4, a driven shaft 5, a driven lower dial 6, Lower cover plate 7, wellhead connecting flange 9, limit mechanism 10, driving lower dial 11, driving shaft 12, driving upper dial 13, driving motor 14, push rod 15, upper flange 16, flange cover 17, Composed of spring 18, drive shaft 19, and feeding motor 20; the upper cover 1 is installed above the shell 2 and welded with the shell 2, the center of the upper cover 1 is provided with a charging hole 21, and the lower cover 7 is installed under the shell 2 And use screws to connect with the housing 2, the center of the lower cover 7 is provided with a feeding hole 8, the upper cover 1, the housing 2 and the lower cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com