Addition and supplement method of reservoir stratum protective solid-phase material of deep well drilling fluid based on solid phase particle size degradation

A technology for reservoir protection and material addition, which is applied in particle size analysis, material analysis, particle and settlement analysis, etc. It can solve reservoir damage, drilling fluid leakage, and can not well grasp the particle size distribution and optimal replenishment timing of supplementary materials. and other problems, to achieve the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

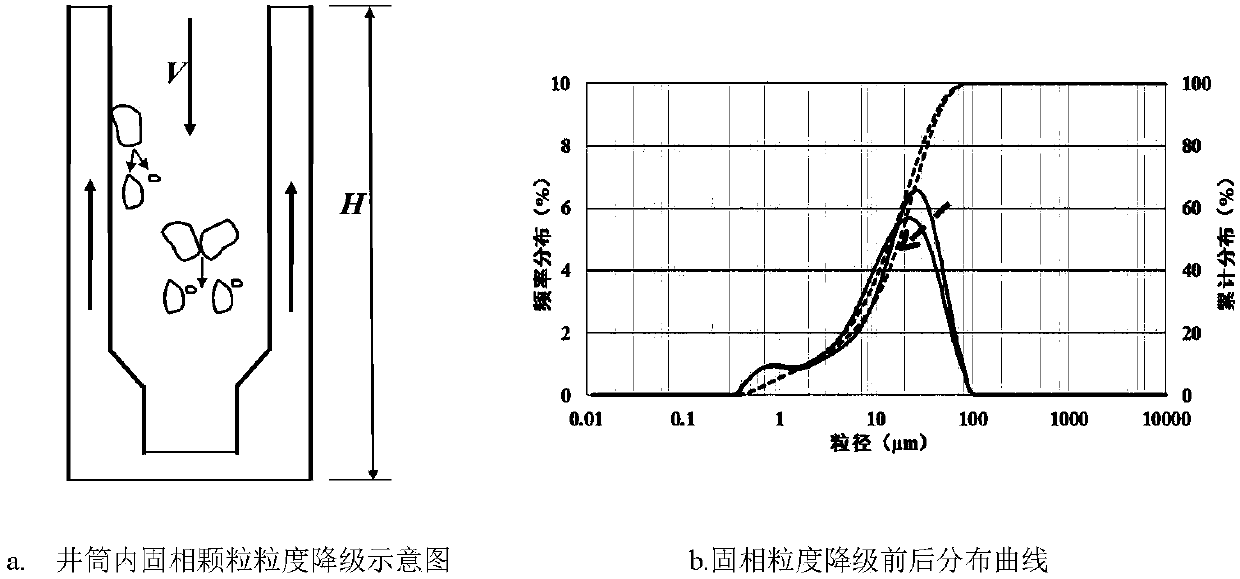

[0020] The content, characteristics and effects of the present invention will be further described in detail below in conjunction with the accompanying drawings. The specific implementation steps of the deep drilling fluid circulation solid phase material replenishment method based on solid phase particle size degradation are as follows:

[0021] (1) According to the shielding temporary plugging gradation theory and the fracture width distribution or pore throat distribution to be drilled into the reservoir, determine the particle size distribution of the drilling fluid solid phase material suitable for drilling into the reservoir;

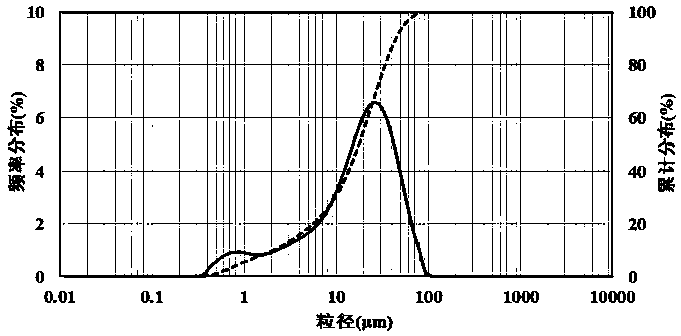

[0022] (2) Using a laser particle size analyzer to test the initial particle size distribution of solid phase particles in drilling fluid ( figure 1 );

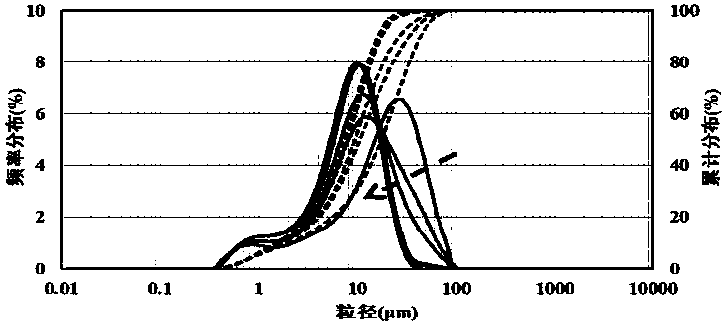

[0023] (3) Simulate the temperature and pressure conditions of the well and the performance of the drilling fluid indoors, and test the influence of the drilling fluid circulation time on the abr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com