Direct-drive hub motor of wheelchair

A hub motor and wheelchair vehicle technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of not having modern vehicle aesthetics, the influence of rotation balance, and occupying the space of the vehicle, so as to achieve large braking force and overall Optimized car structure and short braking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

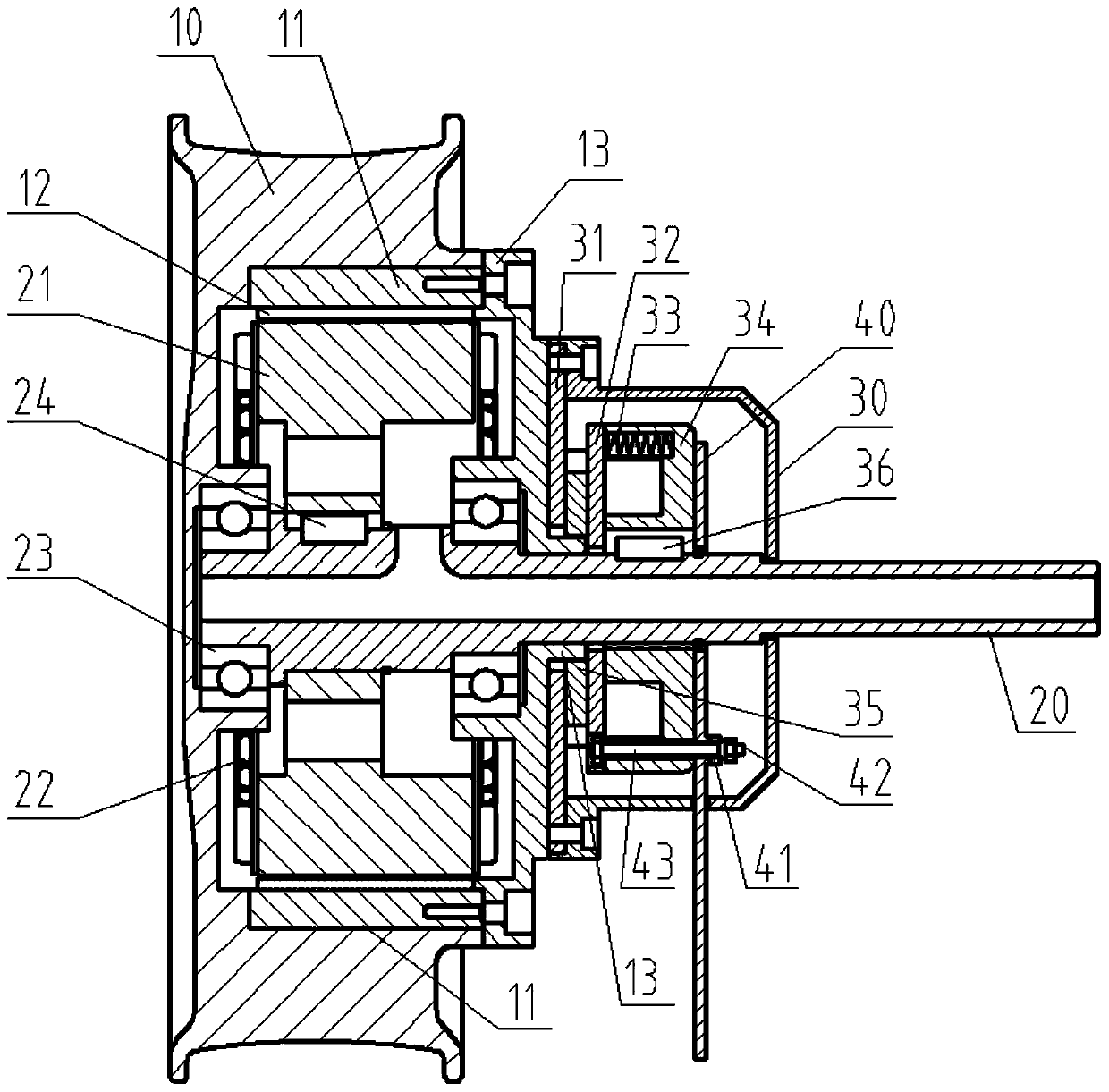

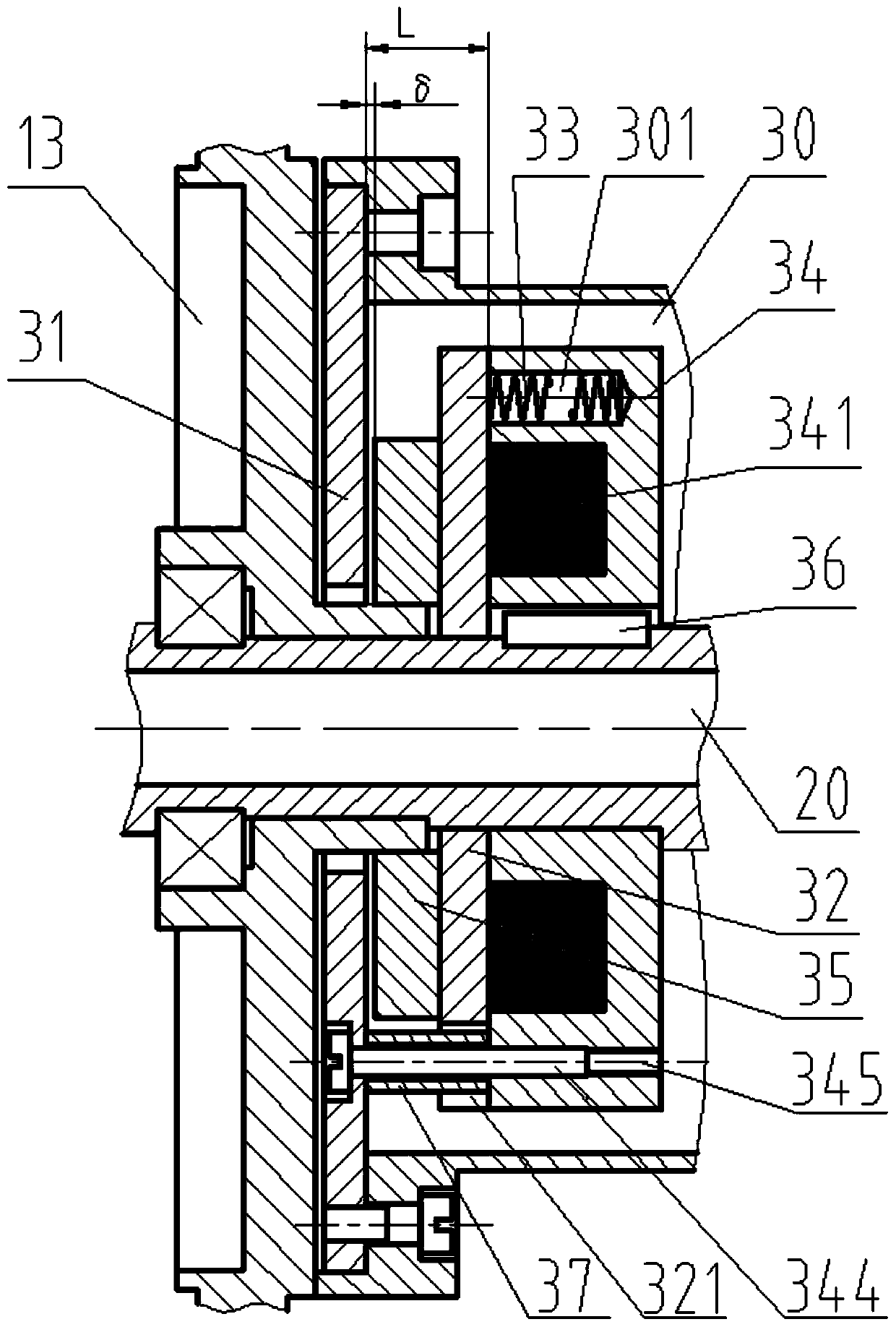

[0039] Such as figure 1 , the motor of this embodiment is mainly composed of a hub 10, a rotor core 11, a magnetic steel 12, a support seat 13, a stator 21, a winding 22, a motor shaft 20, a stator 31, a moving plate 32, a friction plate 35, a spring 33, a magnetic Brake seat 34, unlocking handle 40 and transmission rod 43 form.

[0040] The stator 21 is connected on the motor shaft 20, and is non-rotatably connected with the motor shaft through the key 24, and the winding 22 is arranged at both axial ends of the stator, thus the stator 21, the winding 22 and the motor shaft 20 constitute a stator assembly.

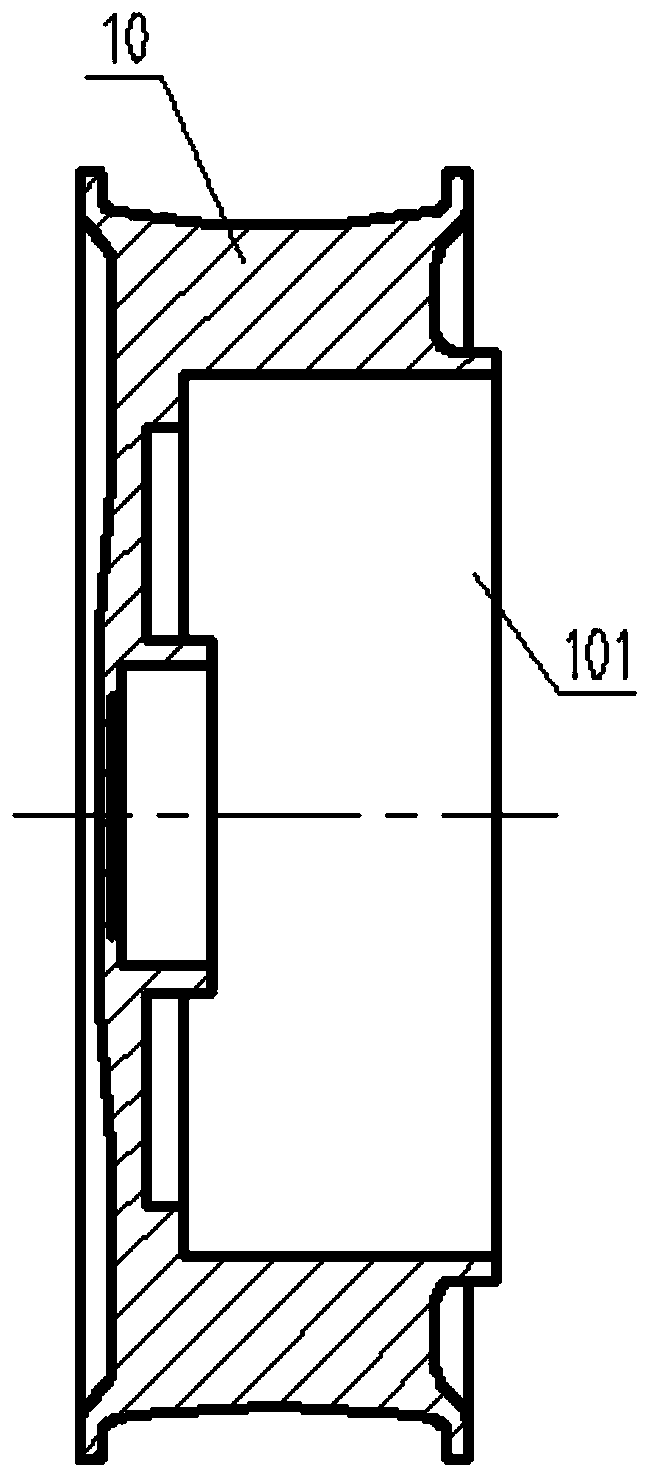

[0041] Such as figure 2 , the axial end of the hub 10 is provided with a rotor groove 101, the rotor core 11 and the magnetic steel 12 are both annular, and the rotor core is fixed on the annular wall surface of the rotor groove of the hub by casting , the magnetic steel is fixedly connected to the inner circular surface of the rotor iron core, thus the hub 1, the roto...

Embodiment 2

[0049] The motor of this embodiment is as Figure 14 As shown, the difference from the above-mentioned embodiment 1 is that the structures of the hub and the rotor core are slightly different, such as Figure 15 , 16 A protruding ring 102 is provided on the circular wall surface of the rotor groove 101 on the hub 10, and an annular groove 111 matching the protruding ring 102 is provided on the circumferential side of the rotor core 11. The rotor groove 101 on the hub is actually produced during casting. The hub and the rotor core are mutually axially limited by the cooperation of the protruding ring 102 and the annular groove 111. Even if the casting joint surfaces of the two are separated due to long-term vibration, the rotor core will not move axially. Therefore, the structure in which the hub and the rotor core are combined with each other in this embodiment makes the rotor assembly have the fewest connecting parts, and the whole is good, so the rotation balance is good. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com