Apparatus and method for twisting hollow rods

A technology of hollow and twisted sleeves, applied in the field of slotted rod devices, which can solve problems such as lack of resistance and difficulty in cross-sectional shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

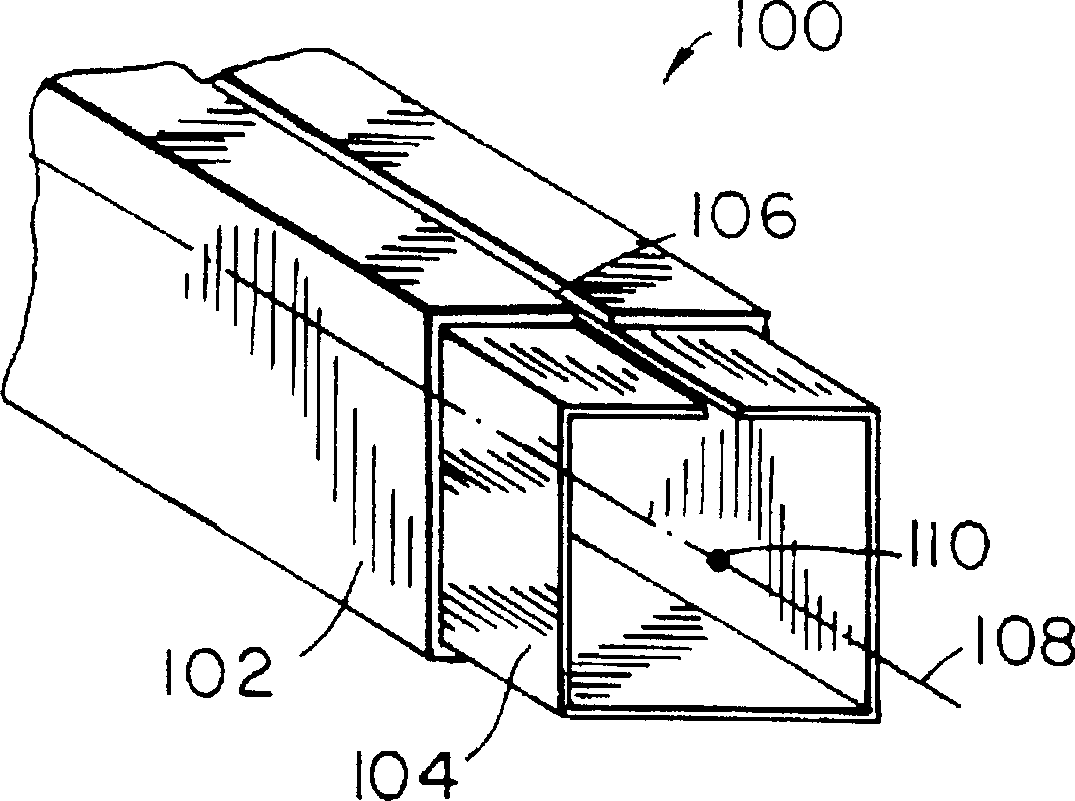

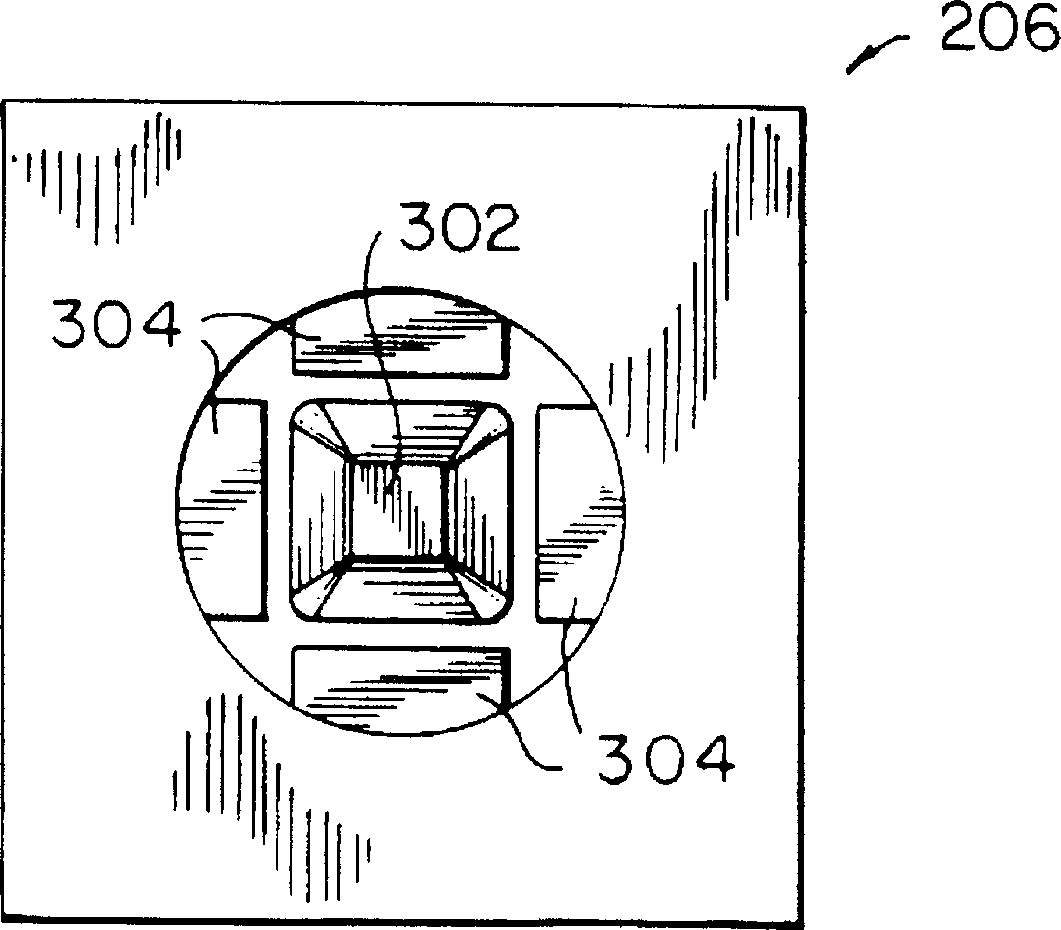

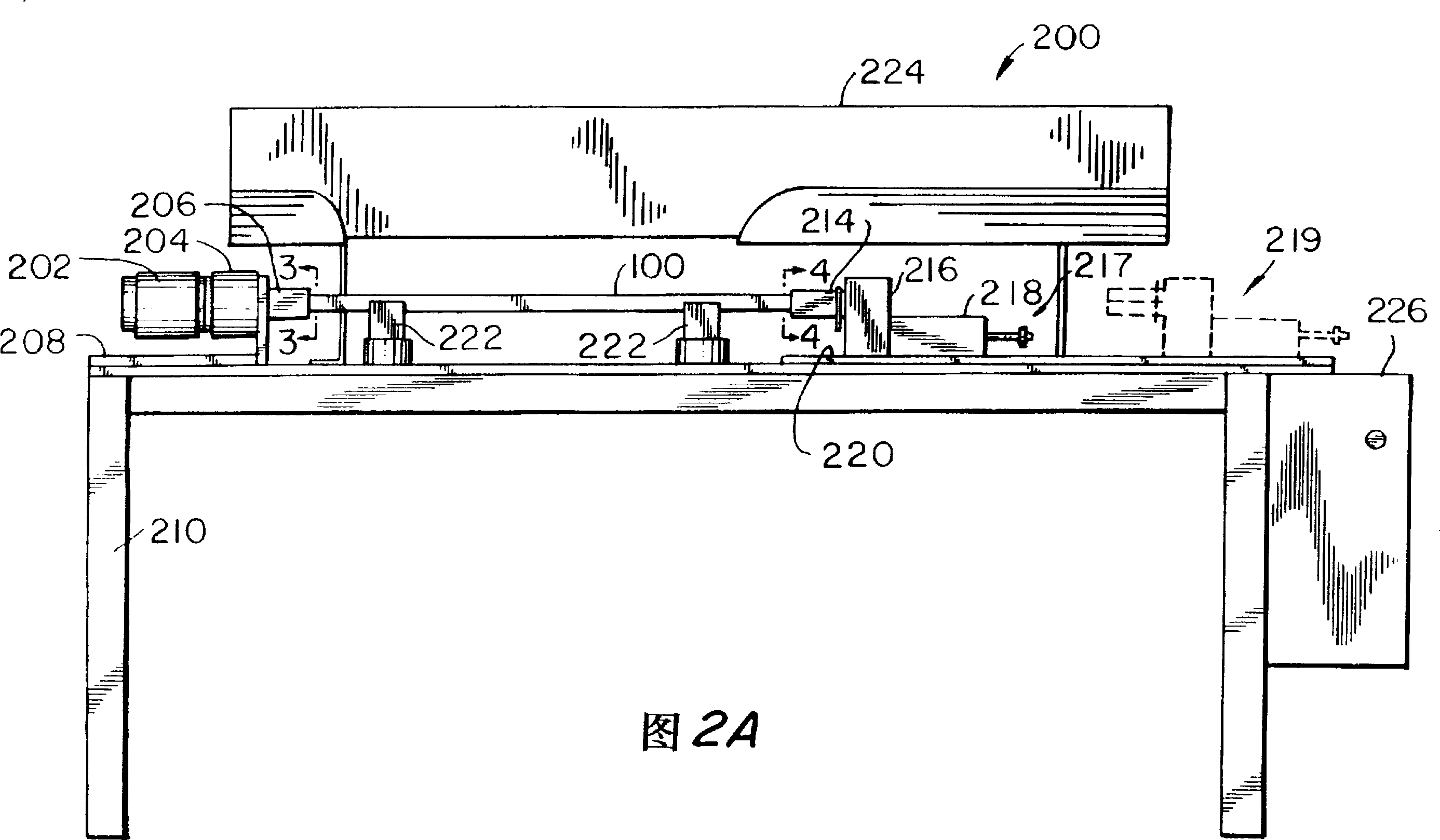

[0030] The present invention provides an apparatus and method for twisting a pair of hollow, slotted rods nested together. Each of the first and second jaws is designed to have male and female features for engaging the inner and outer surfaces of the respective ends of the nested pair of rods. Since the two ends of the paired rods are engaged in such a state, the torsion is basically carried out on the entire length of the paired rods, neither causing the paired rods to warp along the slit, nor causing the formed parts to twist due to torsional stress. Deform both ends of the rod. After twisting, the telescoping function of the twisted paired rods still remains. In particular, the invention can also be used to twist single hollow rods, with or without slots.

[0031] Precise twisting is preferably accomplished with automatic control, stopping the stepper motors when the amount of twist produced on the paired rods is substantially equal to a preset amount. The automatic cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com