Heat superconducting plate and heat superconducting radiator

A technology of thermal superconductivity and heat sink, which is applied in the field of heat transfer, and can solve problems such as poor sealing, malfunction of equipment, failure of plate-fin heat sink, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

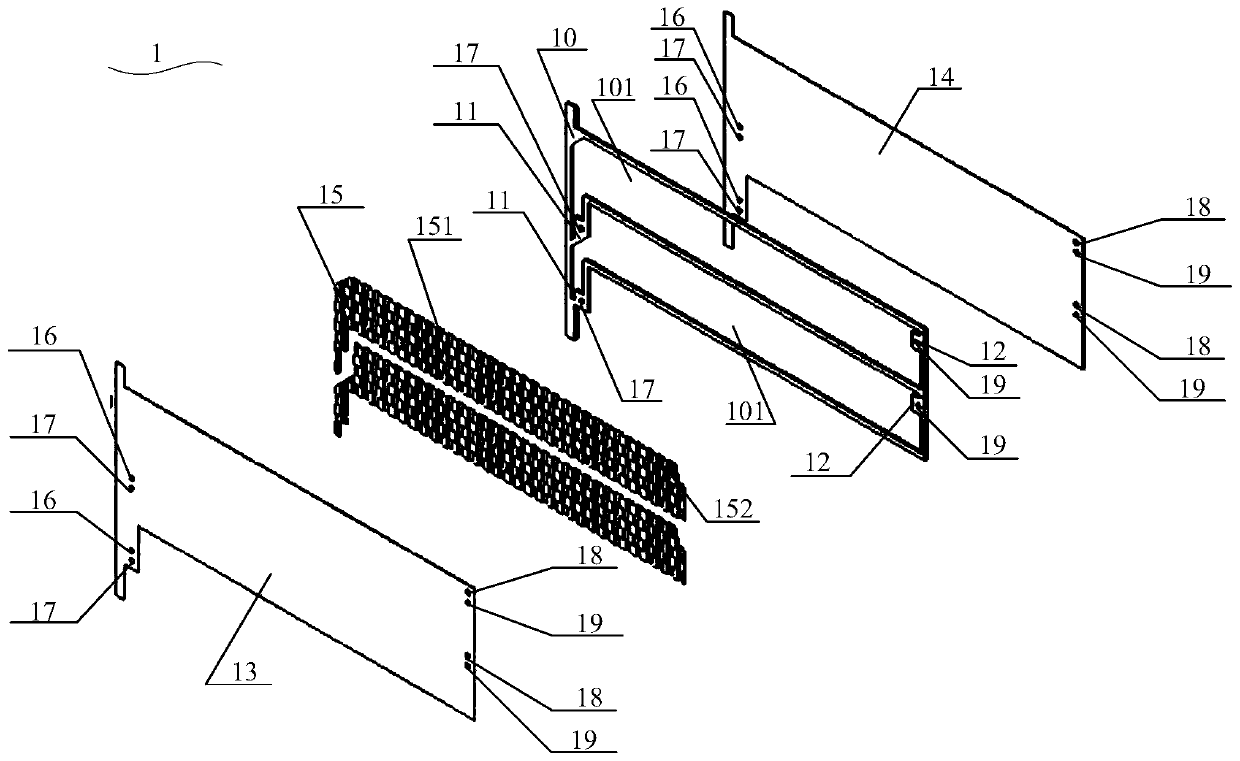

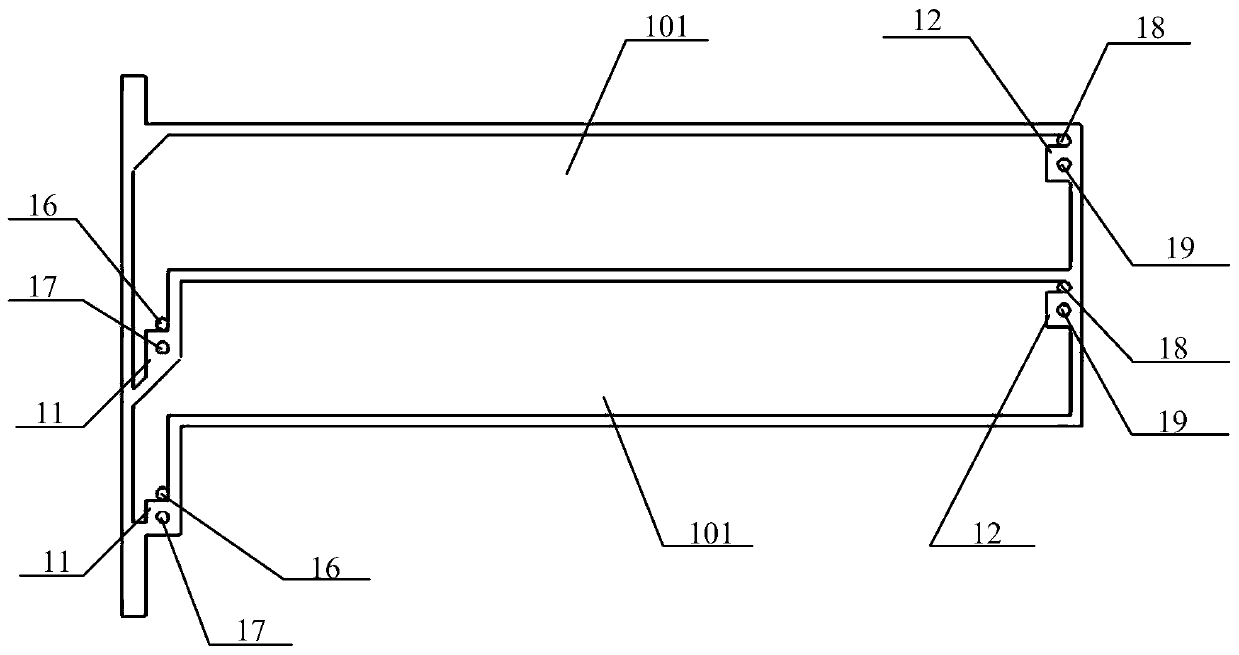

[0122] see Figure 1 to Figure 2 , the present invention provides a kind of thermal superconducting plate 1, and described thermal superconducting plate 1 comprises: a plurality of mutually independent closed cavities (not shown); One side extends to the opposite side, and each of the closed cavities is provided with a thermal superconducting heat transfer channel (not shown), and the thermal superconducting heat transfer channel is filled with a heat transfer working medium ( not shown); the first bump 11, the first bump 11 is located at one end of each closed cavity, the thickness of the first bump 11 is the same as the height of the closed cavity; the second bump Block 12, the second bump 12 is located at one end of each closed cavity away from the first bump 11, the thickness of the second bump 12 is the same as the height of the closed cavity; the first liquid Phase balance communication hole 16, the first liquid phase balance communication hole 16 is located at one end ...

Embodiment 2

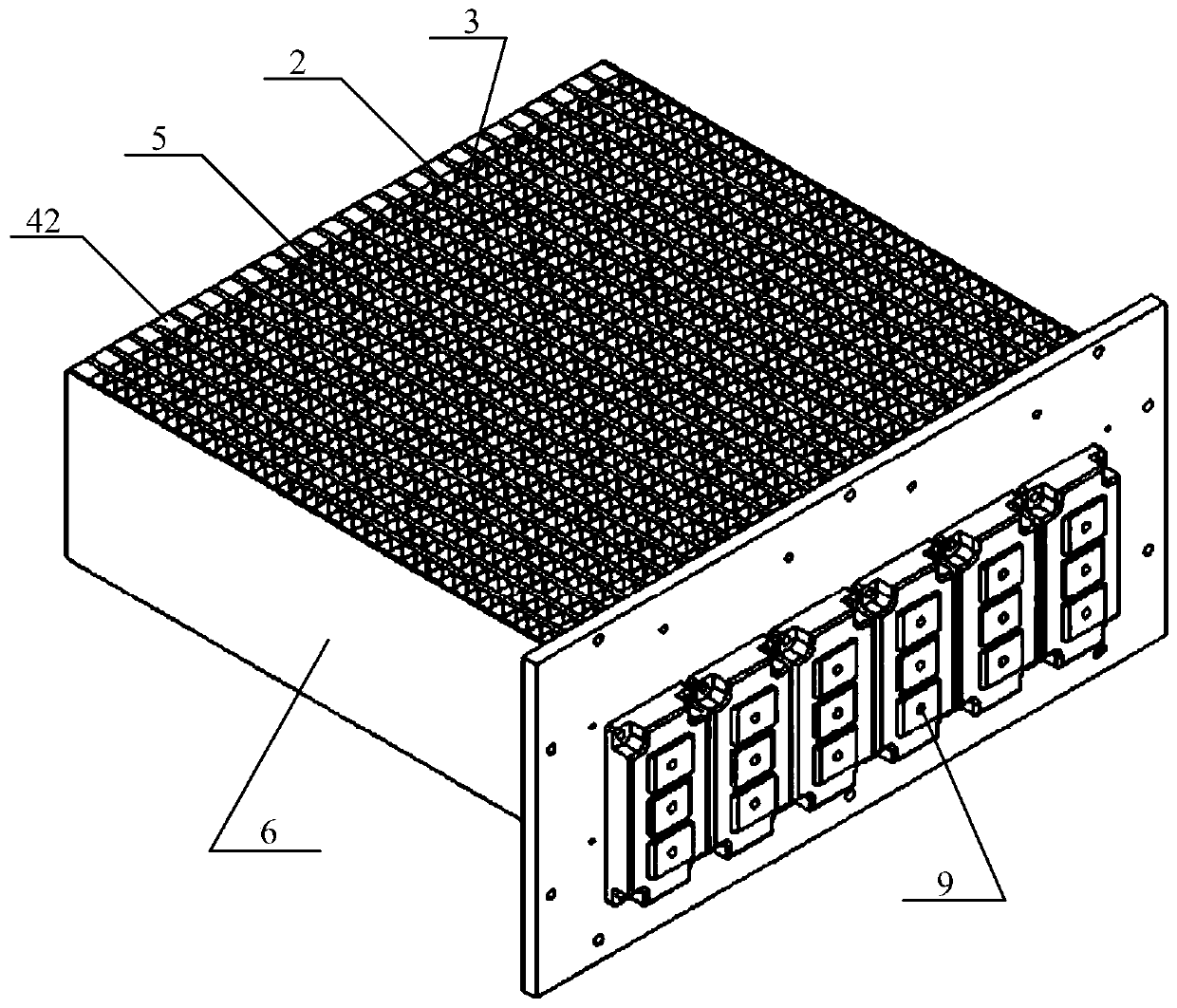

[0137] Please combine Figure 1 to Figure 2 refer to Figure 3 to Figure 10 , this embodiment also provides a thermal superconducting heat sink, the thermal superconducting heat sink includes: a number of first thermal superconducting plates 2 and second thermal superconducting plates 3 alternately arranged at intervals; each of the first thermal superconducting plates A plurality of independent first closed cavities (not shown), first bumps 21 and second bumps 22 are formed in a thermal superconducting plate 2, and each of the first closed cavities starts from the first One side of a thermal superconducting plate 2 extends toward the opposite side, and each of the first closed cavities is provided with a first thermal superconducting heat transfer channel (not shown), and the first thermal superconducting channel (not shown) The hot channel is filled with heat transfer medium (not shown); the first bump 21 is located at one end of each first closed cavity, and the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com