Six-axis type dicing machine

A dicing machine and dicing technology, used in metal processing and other directions, can solve the problems of uneven cutting materials, uneven edges of candy, and cutting knives that are easy to stick to raw materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

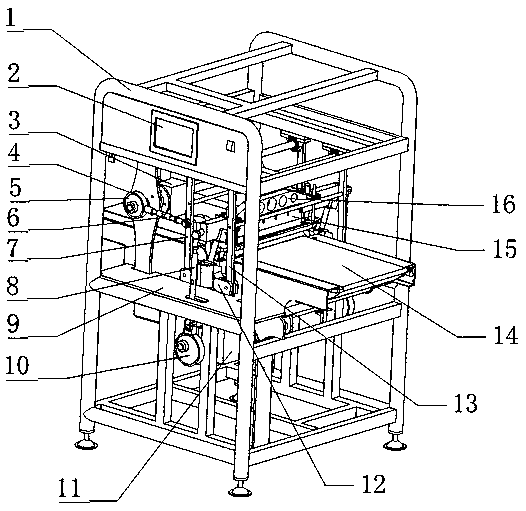

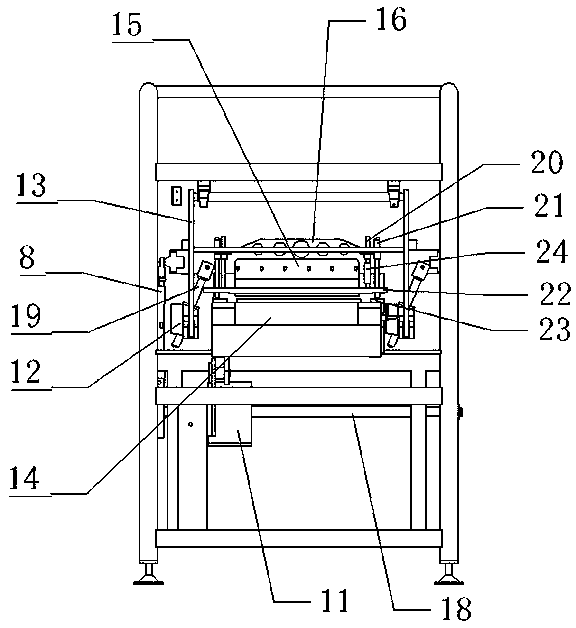

[0034] Such as Figure 1 to Figure 4 As shown, a six-axis cutting machine includes a frame 1. The frame 1 includes a plurality of columns and a plurality of beams. The columns of the frame are vertically arranged with the beams. The columns include four main columns and a plurality of branch columns. Three-layer beams are arranged between the four main columns, and the three-layer beams include a lower beam, a middle beam and an upper beam, and multiple branch beams are arranged in each layer beam. A conveying device and a cutting device are installed on the frame 1, and the conveying device is used for feeding and outputting materials.

[0035] The block cutting device includes a cutter mechanism, a block cutting power mechanism, two groups of symmetrically arranged block cutting transmission mechanisms and two groups of guide mechanisms, and the cutter mechanism is arranged on the upper part of the conveying device. The cutting power structure includes a first motor 11, the...

Embodiment 2

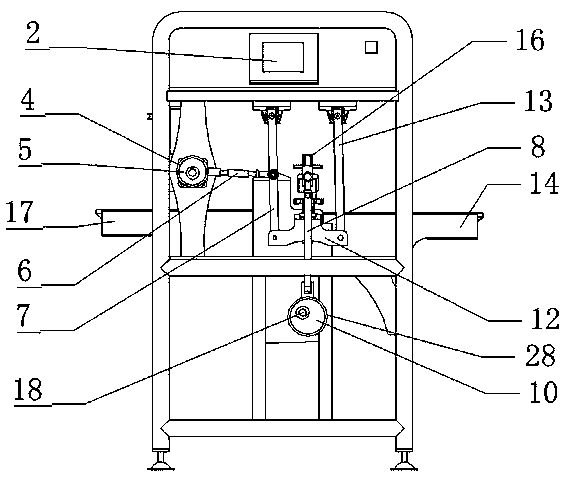

[0047] Such as Figure 5 to Figure 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the cutting power mechanism and the cutting transmission mechanism in this embodiment are different, specifically, the cutting power mechanism includes a first motor 11 , the first motor 11 is arranged on the top of the tool rest 16, the first motor 11 is connected to the first power shaft, the first motor 11 drives the first power shaft to rotate, the first power shaft is connected with the first eccentric wheel 10, the first eccentric wheel 10 The center line of the first power shaft is set eccentrically with the center line of the first power shaft. The outer circular surface of the first eccentric wheel 10 is sleeved with a first collar 28. The first eccentric wheel 10 can rotate relative to the first collar 28. The first set The outer circular surface of the ring 28 is fixedly connected with a first connecting rod 29, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com