Robot shock-absorbing track

A technology of robots and crawlers, which is applied in the field of robots, can solve problems such as inconvenient maintenance, damage to internal precision components, and difficult installation and disassembly of crawlers, and achieve better results, convenient disassembly and installation, and simple connection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

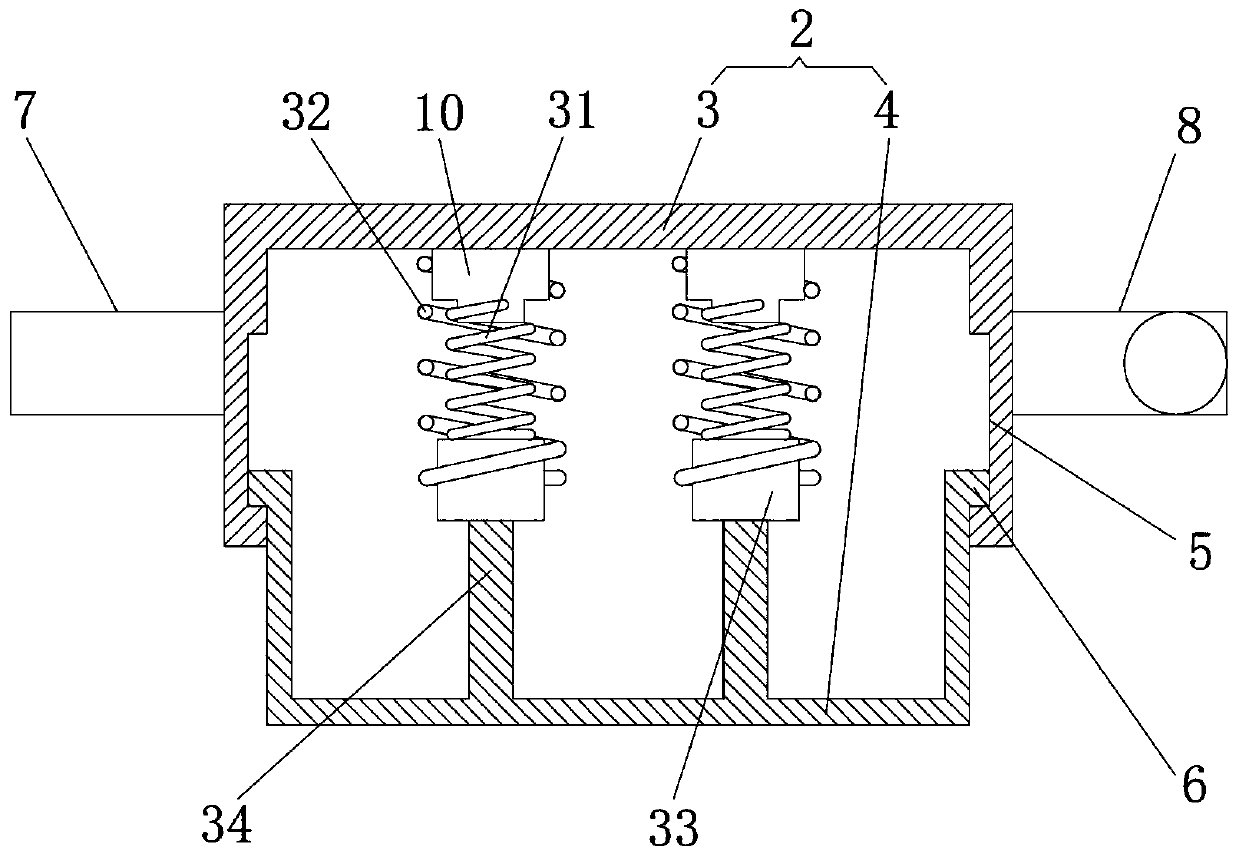

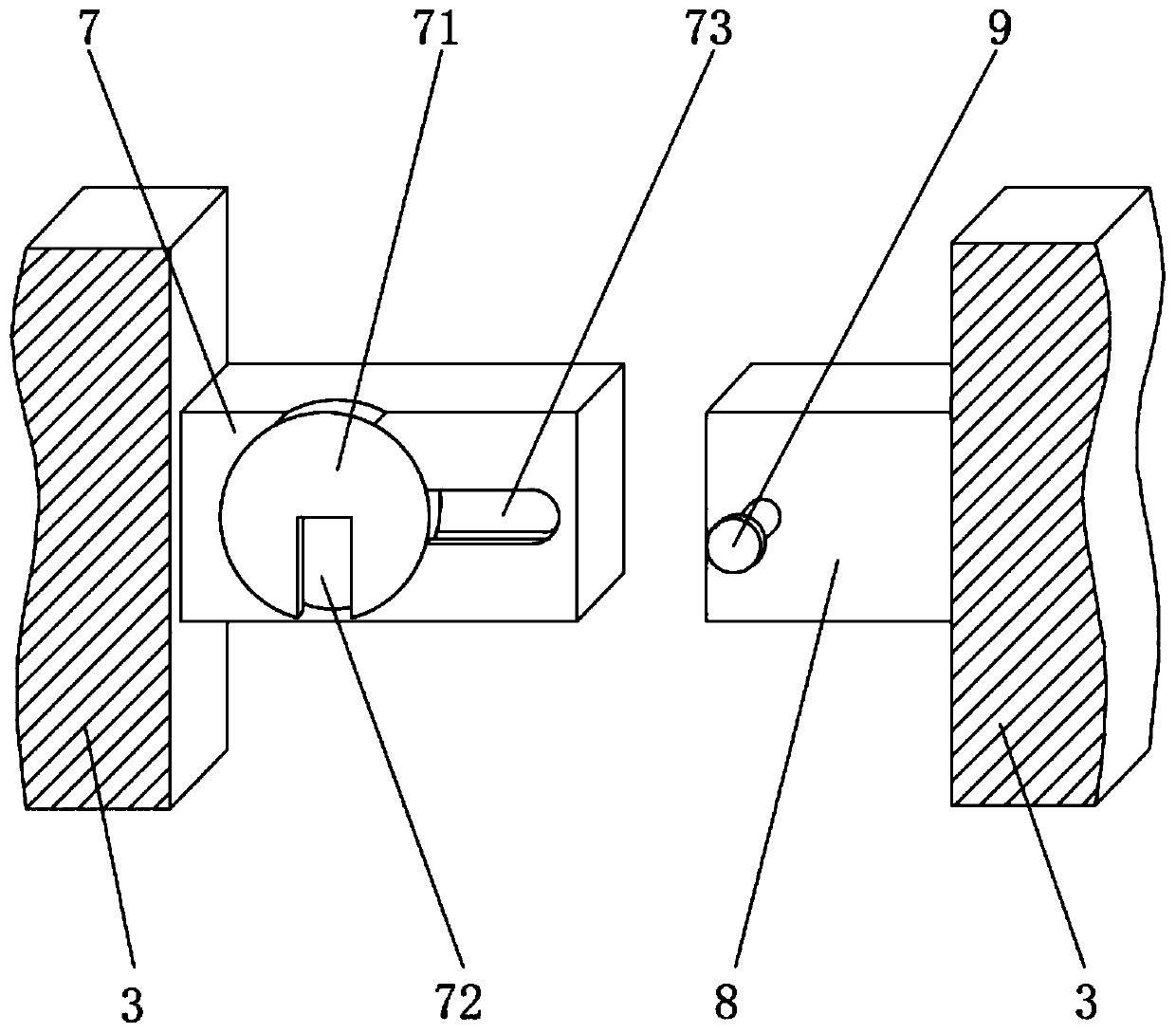

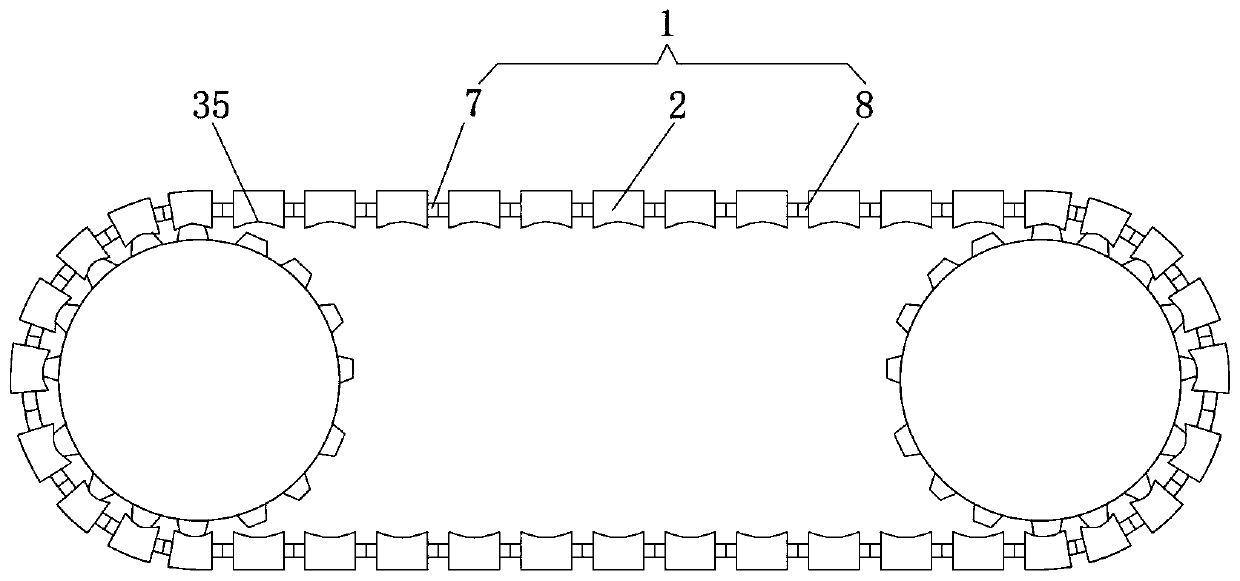

[0034] see Figure 1-3 , this embodiment provides a robot shock-absorbing crawler, including a crawler 1, and the crawler 1 includes a plurality of movable blocks 2, and the movable block 2 includes a shock-absorbing cabin 3 and a transmission cabin 4, and the inner wall of the shock-absorbing cabin 3 is provided with a card slot 5 , the top of the outer wall of the transmission cabin 4 is provided with a block 6 matching the slot 5, the shock-absorbing cabin 3 and the transmission cabin 4 are movably clamped, and the two ends of the shock-absorbing cabin 3 are provided with the same body with the lug 7 and the lug 8.

[0035] Wherein, the inner wall of the shock-absorbing cabin 3 top side is fixed with insulating block 10, and insulating block 10 is rubber material, can make coil 32 keep the state of circuit disconnection by insulating block 10, can make the effect of electromagnetic damping shock absorption better, and insulation The block 10 is T-shaped, which can facilitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com