A quick disassembly and assembly method thereof

A processing method and fast technology, applied in aircraft assembly, aircraft parts, transportation and packaging, etc., can solve the problems of insufficient machining accuracy of quick disassembly parts, affecting the use of quick disassembly parts, wear and tear of disassembly surfaces, etc. Lubrication effect, ease of processing, and vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the examples, but the structure of the present invention is not limited to the following examples.

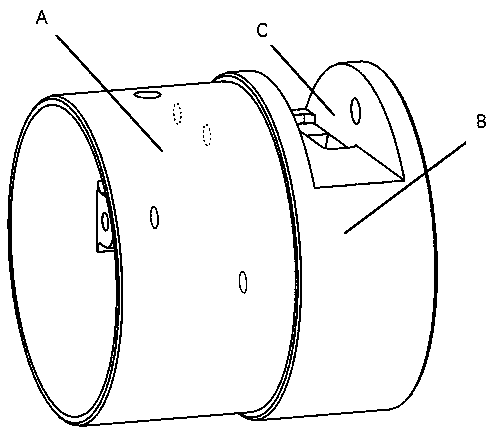

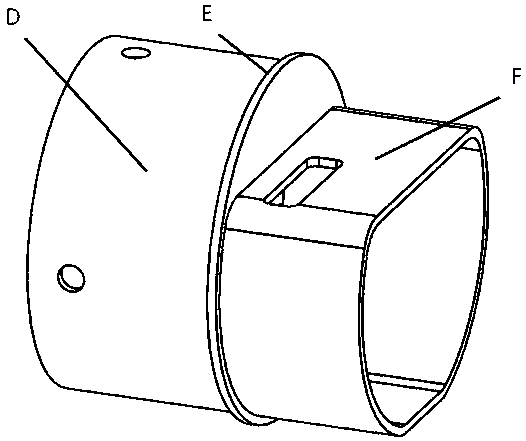

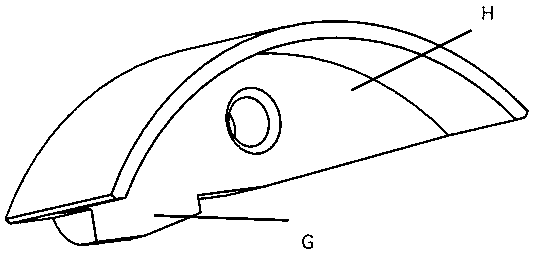

[0015] A quick disassembly and assembly part, including inserts, hoops, clamps, pins, retainers and torsion springs, wherein the inserts, hoops and clamps are made of aviation aluminum alloys, and the composition of aviation aluminum alloys includes: 0.25% Cr, 1.0% Fe, 0.5% Mn, 0.8% Mg, 6-8% Si, 1.0% Zn, 0.05-0.22% Ti, 5% Cu, 0.15% Pb.

[0016] The processing steps of the hoop are as follows: (1) Cut off a 40mm aluminum alloy bar with a saw machine; (2) Perform solid solution treatment on the cut aluminum alloy billet, the solution temperature is 530°C, and the solution time is 1 (3) Fix the blank on the platform fixture of the CNC lathe, and carry out rough turning, semi-finishing turning and finishing turning on both ends of the surface until the length is 38mm; (4) Change the clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com