A compound bottom hole gate with sand discharge function

A gate and duplex technology, applied in the field of duplex bottom hole gates, can solve the problems that the gate cannot be opened in time, the gate opening force of the gate is reduced, and the normal opening is affected, so as to avoid serious overload of the gate opening force, controllable gate opening force, Easy-to-operate effects

Active Publication Date: 2021-05-25

赵永宪 +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when the thickness of the silt accumulated over time exceeds the gate of the bottom hole, the adhesive force generated by it is too large. When the double guide rail inclined plane steel gate is opened, it needs to overcome the silt adhesion and separate from the silt to open. This application Although the disclosed structure reduces the friction between the inclined plane steel gate and the silt during opening, it is also difficult to overcome the adhesion force generated by the silt when the bottom hole gate is opened. Overloading, affecting the normal opening of the problem

And because the inclination angle of the plane steel gate of the structure disclosed in this application is less than or equal to 10°, relative to the combined effect of the water pressure at the bottom of the dam and the adhesion force produced by sediment deposition, the degree of reduction in the opening force of the gate to open the gate is Limited, it can only be said that to a certain extent, it has partially solved the problem that the gate cannot be opened in time due to sedimentation.

Moreover, when the thickness of the silt exceeds the bottom hole gate, even if the bottom hole gate is opened, the silt is below the water surface, and the silt cannot be discharged normally.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0021] Embodiment 2, this embodiment This embodiment is basically the same as Embodiment 1, except that two compound small gates 5 are arranged at the bottom of the bottom hole gate.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

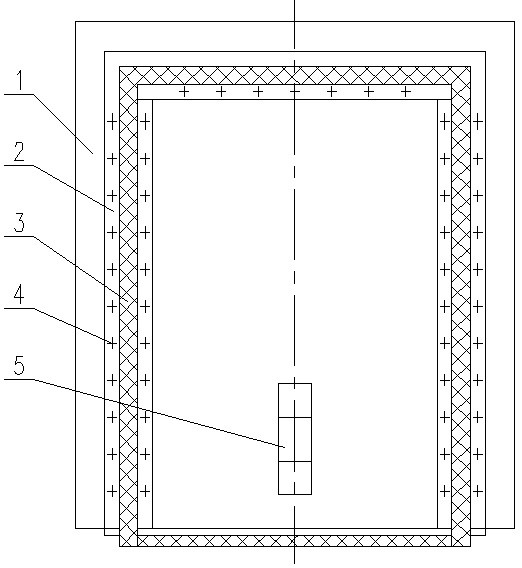

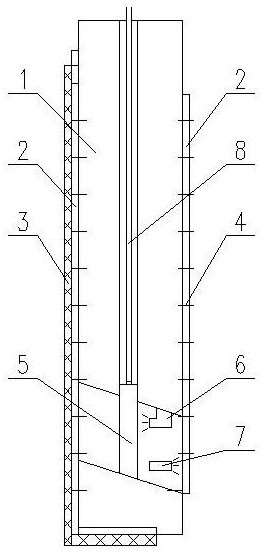

The present invention is a compound bottom hole gate with sand discharge function, which includes a bottom hole gate, and is characterized in that it also includes a compound small gate, a running water channel is arranged on the bottom hole gate, and the compound small gate is placed in the bottom hole Vertical displacement can be generated between the small compound gate and the bottom hole gate at the flowing water channel where the gate is set, and in the bottom hole gate. The working process is: when opening the bottom hole gate, first open the double small gate, the upper water spray pipe sprays water towards the upstream, the lower water spray pipe sprays water towards the downstream, and the mud-water mixture discharged from the flow channel is discharged into the bottom hole gate farther away. Downstream, with the relay sand discharge effect of the upper water spray pipe and the lower water spray pipe, the silt and sand in front of the bottom hole gate will form a cavity, and the water in the reservoir area will communicate with the compound small gate, and the sediment in front of the bottom hole gate will follow The water flow is quickly discharged into the downstream. When all the silt in front of the bottom hole gate is removed, the sediment adhesion is zero. At this time, the bottom hole gate is opened, and the reservoir silt can be completely removed.

Description

technical field [0001] The invention belongs to the field of dams, relates to the sand discharge of bottom hole gates, and is a compound bottom hole gate with the function of sand discharge. Background technique [0002] Reservoir sedimentation is currently an unsolvable problem. Some reservoirs use bottom hole gates to discharge water and sand. The gate cannot be opened in time and causes an accident. There are also some reservoirs which are designed with silt storage capacity. As the silt storage capacity is gradually saturated, the economic benefits of the reservoir will drop sharply. [0003] The application number is 2011101561419, and the invention patent application named the double guide rail inclined plane steel gate system discloses a parallelogram double guide rail inclined plane steel gate structure. Through the parallelogram double guide rails, the plane steel gate has a certain inclination angle , in order to reduce the sliding friction between the panel of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E02B7/20E02B8/02

CPCE02B7/20E02B8/02

Inventor 赵晓霞赵永宪

Owner 赵永宪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com