Process for forging pressing jaw of ingot body of steel ingot

A technology of pressing jaws and steel ingots, which is applied in the field of steel ingot ingot body pressing jaws forging technology, which can solve the problems of limited forging space of forging equipment and limited lifting load of forging process, so as to avoid serious overload operation and reduce bearing load requirements, the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

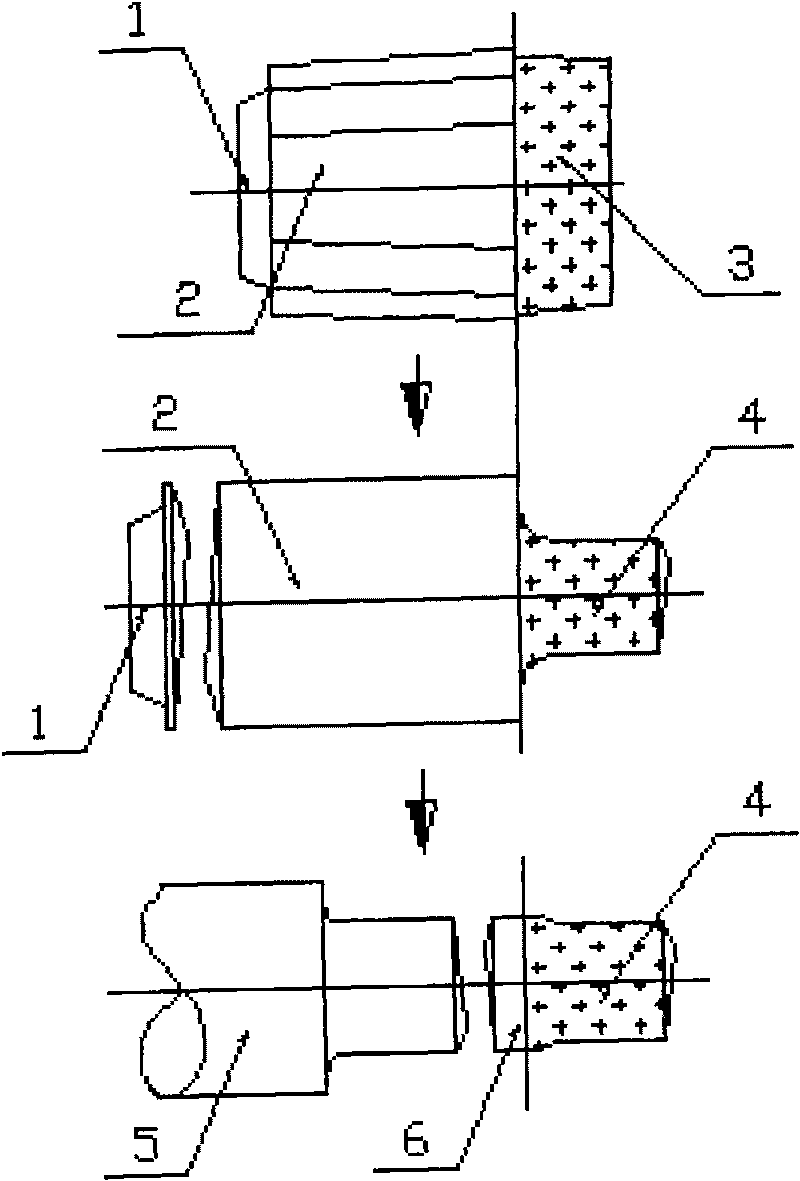

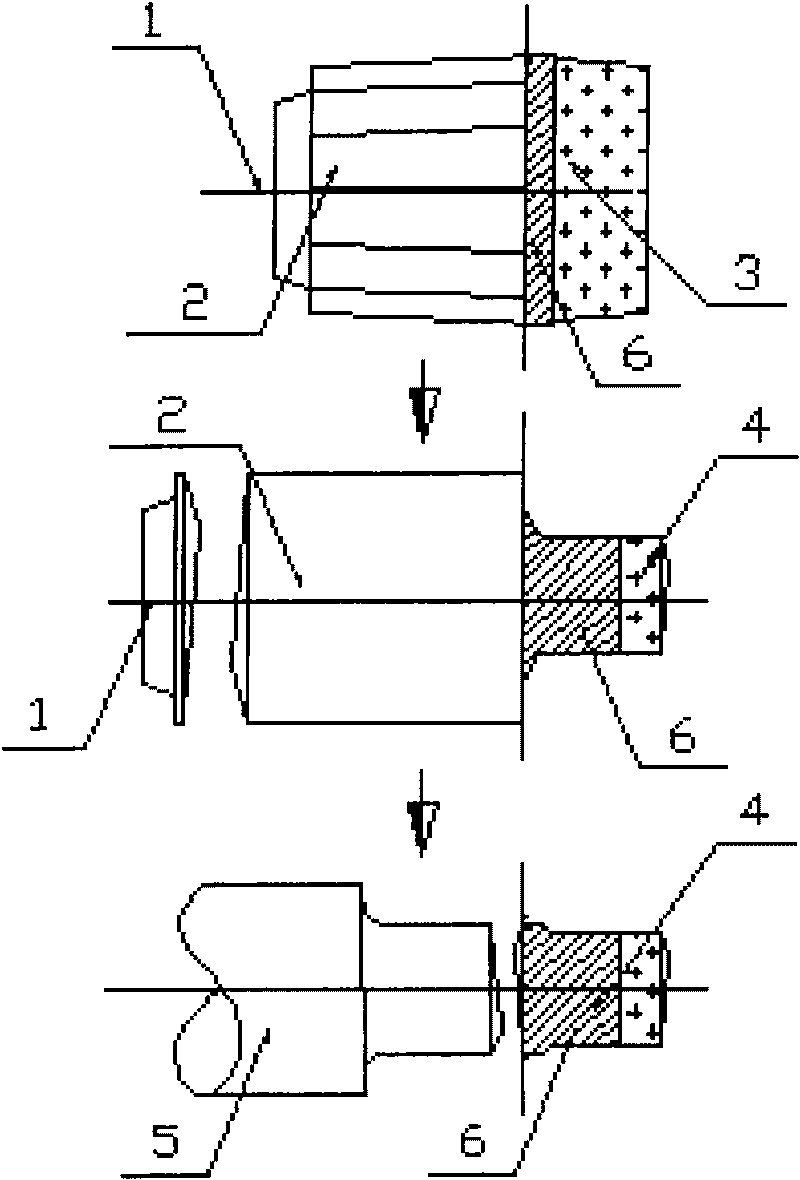

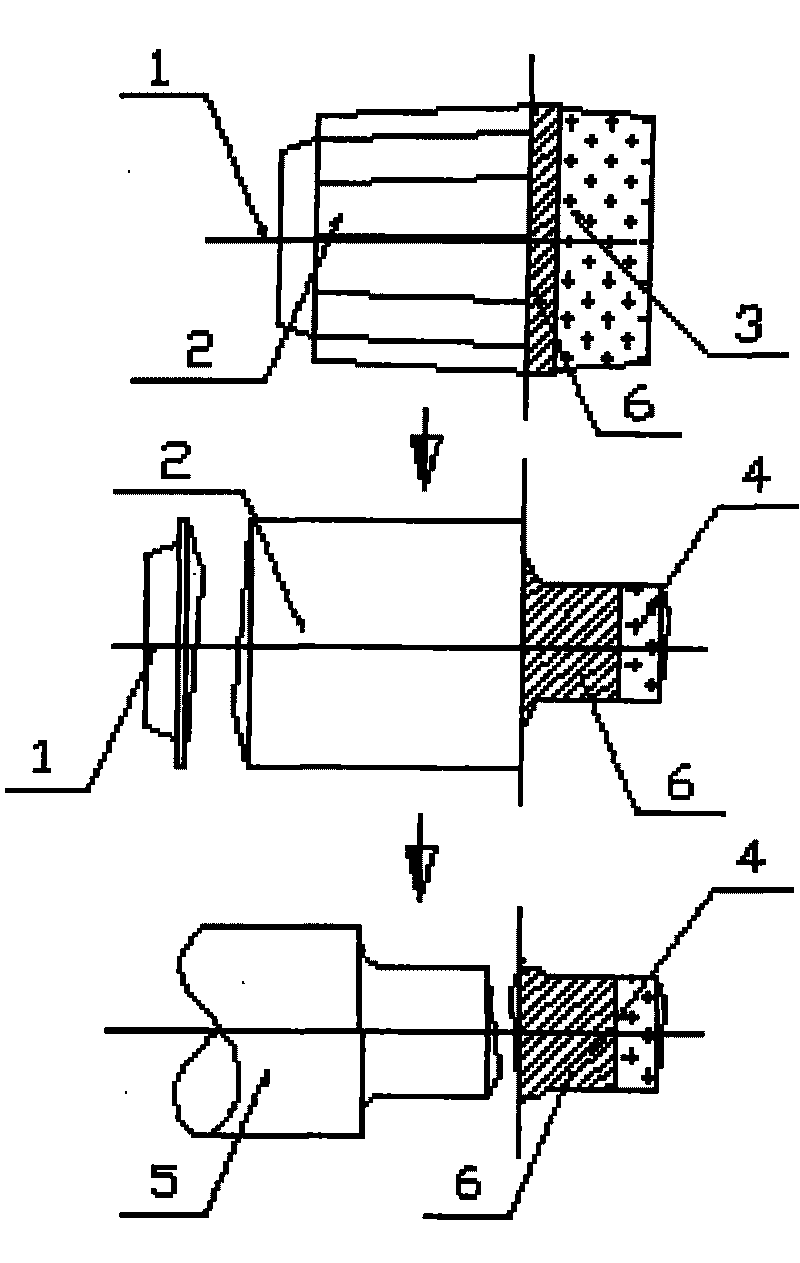

[0026] A 38000mm rolling mill back-up roll in a steel mill has a net weight of 129 tons, a forging of 165 tons, a steel ingot size of 259 tons, a steel ingot nozzle of 4.31 tons, a steel ingot body of 207.9 tons, and a steel ingot riser of 46.65 tons. It is forged by a 12,500-ton hydraulic press. The jaw forging process is as follows:

[0027] Use the plate chain of the steel turning machine to cover the end of the steel ingot nozzle; put the remaining riser of the steel ingot and the steel ingot body 250mm in the same amount removed by the riser process together between the upper and lower anvils of the hydraulic press, and turn it up to Φ1280mm, reserve 1700mm Long, cut off the remaining 45 tons of riser material, that is, complete the operation jaw process of the steel ingot ingot body. Then pre-draw the remaining ingot body to Φ2550mm, and cut off the steel ingot nozzle. At this time, the length of the billet is 4770 mm, and the actual weight of the steel ingot is 206.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com