Mortar paving device for wall masonry

A wall and mortar technology, applied in the field of building masonry, can solve the problems of waste of manpower and time, high construction cost, etc., and achieve the effect of improving applicability, good paving process, and ensuring the quality of mortar joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

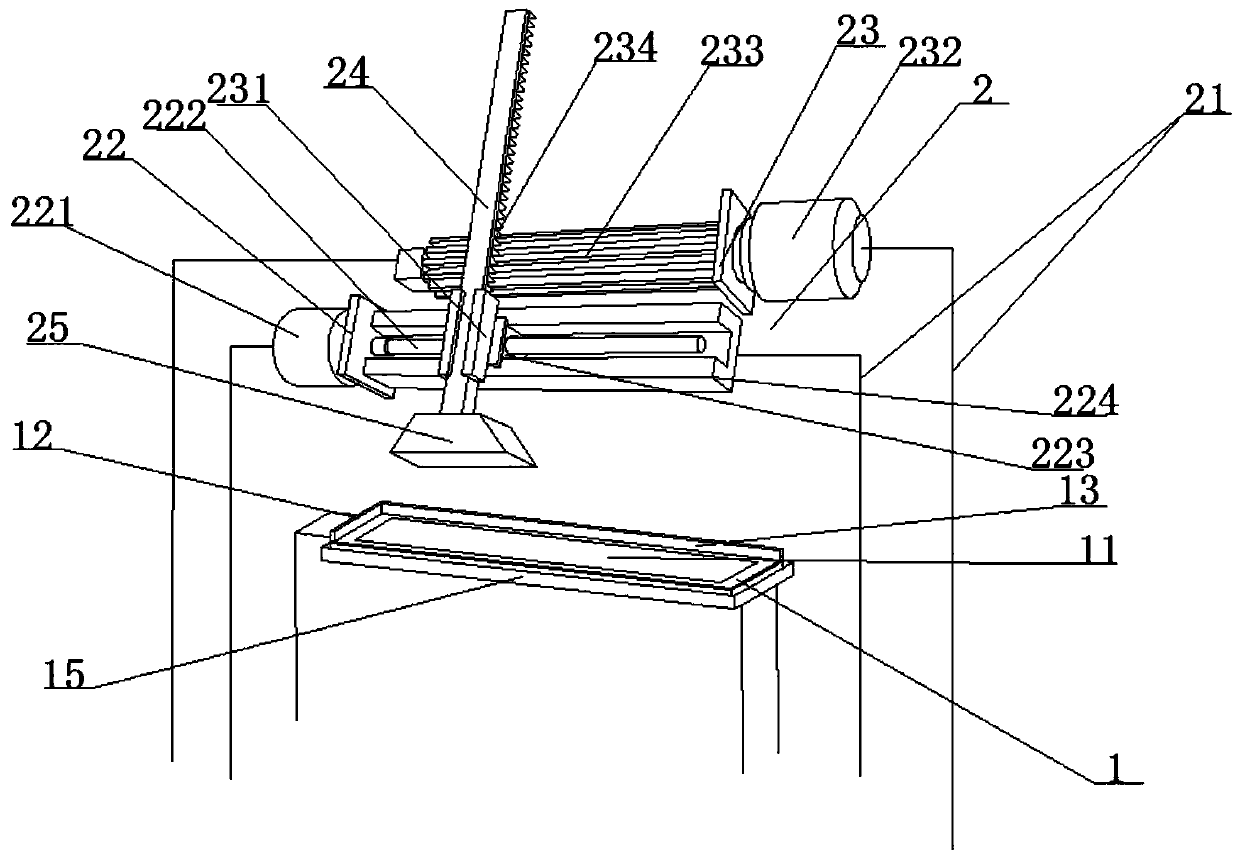

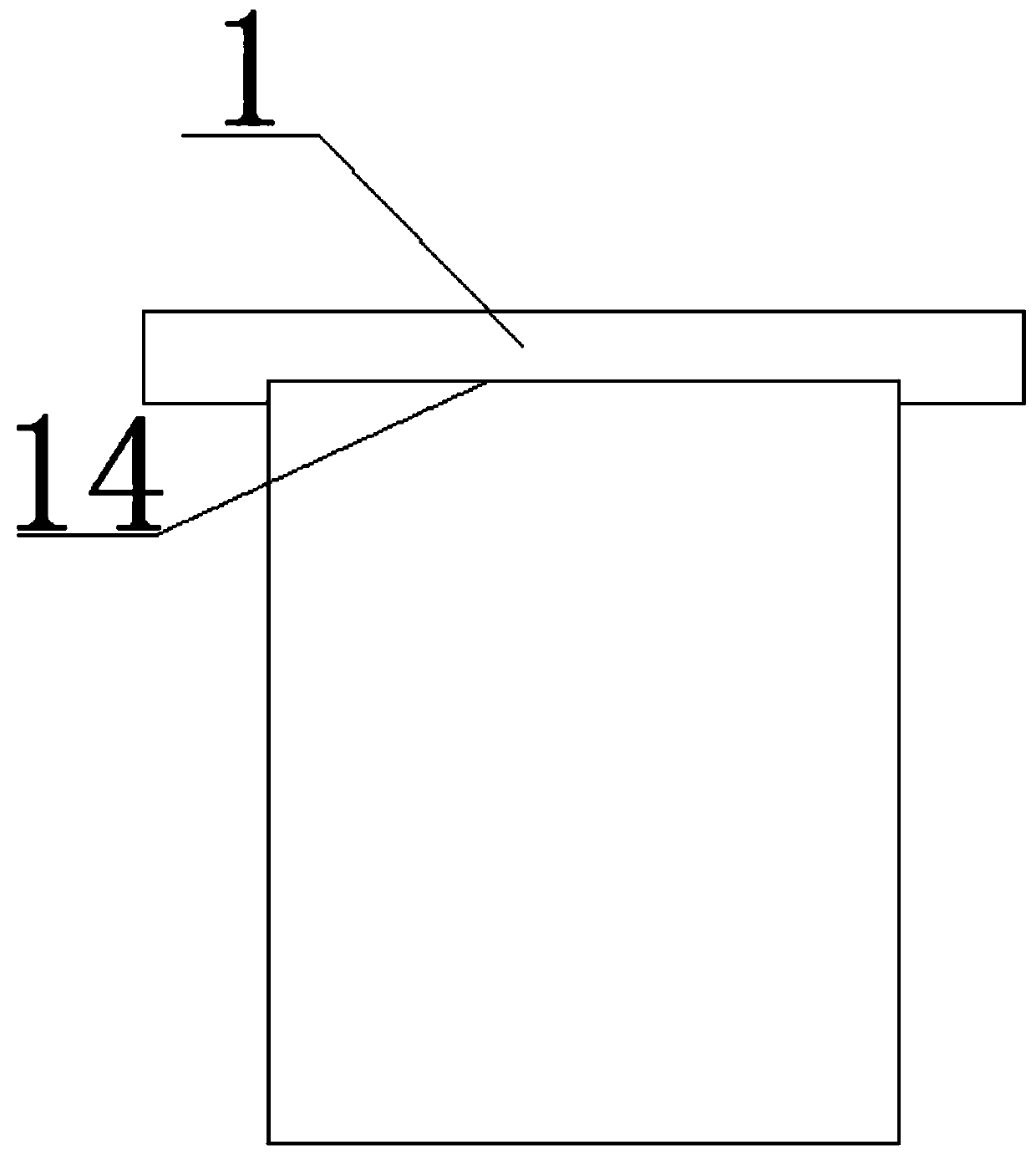

[0023] A mortar paving device for wall masonry, comprising a horizontal paving slab 1 arranged above the masonry material, the horizontal paving slab 1 is provided with strip-shaped horizontal paving holes 11, and the horizontal paving slab 1 A short side is provided with a first vertical positioning plate 12, and one of the long sides of the horizontal paving slab 1 is provided with a second vertical positioning plate 13, and the first vertical positioning plate 12 and the second vertical positioning plate 13 are vertically connected, and the lower surface of the horizontal paving board 21 is provided with a first slot 14 for clamping the horizontal paving board 1 on the masonry material, and a paving mechanism 2 is arranged above the horizontal paving board 1, The paving mechanism 2 includes a frame 21 on which a horizontal moving device 22 and a vertical moving device 23 are fixed. Rod 24 , the paving rod 24 is connected with the vertical moving device 23 and driven by the ...

Embodiment 2

[0025] On the basis of Embodiment 1, the horizontal movement assembly 22 includes a first servo motor 221, the output shaft of the first servo motor 221 is connected with a screw 222, and the screw 222 is threaded with a slider 223, The screw mandrel 223 is provided with a slide rail 224, the slide block 223 is adapted to the slide rail 224 and can move along the length direction of the slide rail 224 in the slide rail 224, and the slide block 223 is provided with a vertical sliding sleeve 231 , the spreading bar 4 is arranged in the vertical sliding sleeve 231 , the spreading bar 1 is adapted to the vertical sliding sleeve 31 and can move in the vertical sliding sleeve 31 along the length direction of the vertical sliding sleeve 231 .

Embodiment 3

[0027] On the basis of Embodiment 1 or 2, the vertical movement assembly 23 includes a second servo motor 232, the output shaft of the second servo motor 232 is connected with a gear 233, and the axis of the gear 233 is connected to the axis of the slide rail 223 In parallel, the end surface of the paving bar 4 close to the gear 233 is provided with a rack 234 meshing with the gear 233 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com