High-precision sampler used for coal detection

A sampler, high-precision technology, applied in the direction of sampling devices, etc., can solve the problems of inconvenient operation, low sampling efficiency, difficult movement, etc., and achieve the effect of easy movement, continuous sampling, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

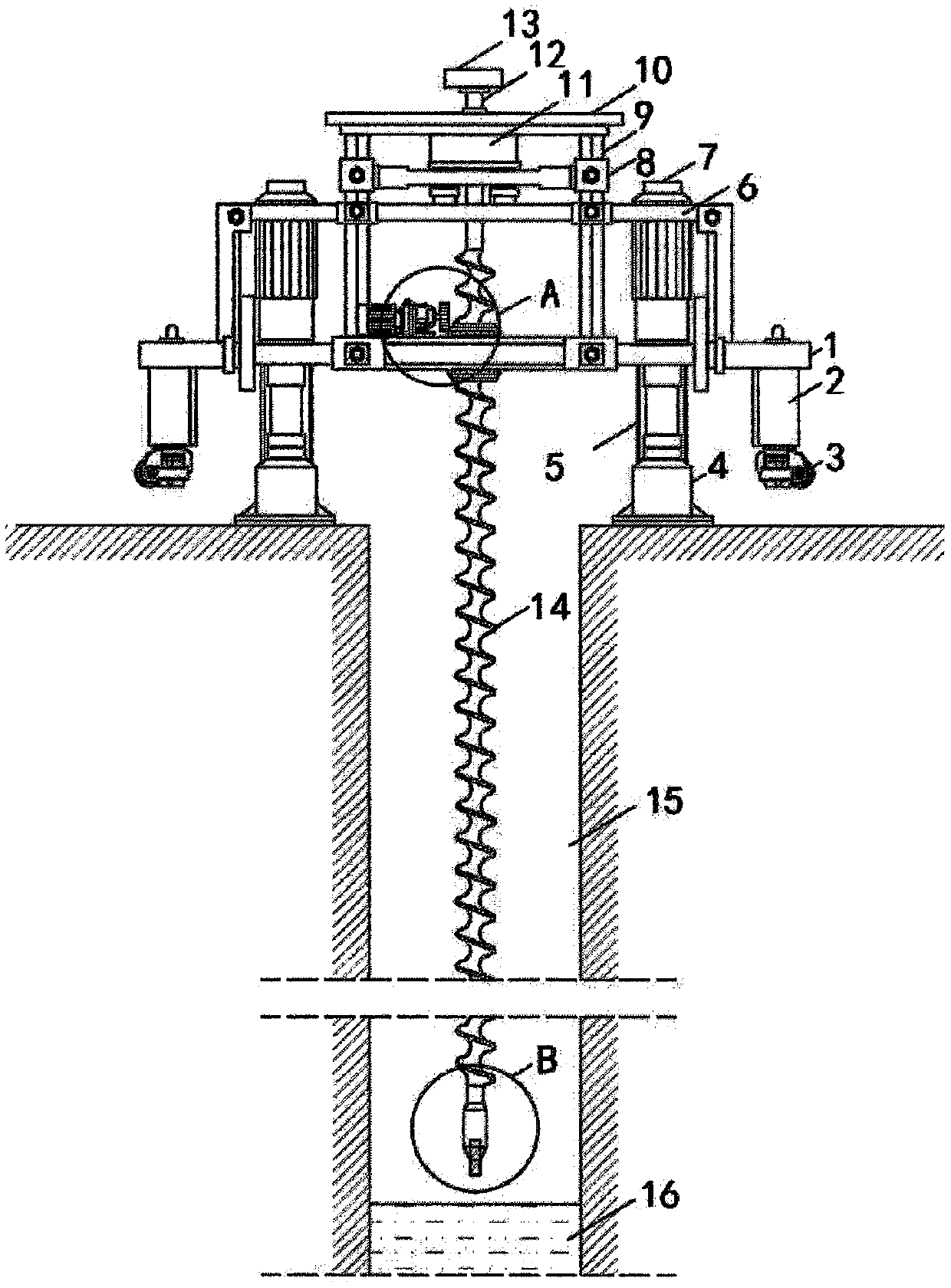

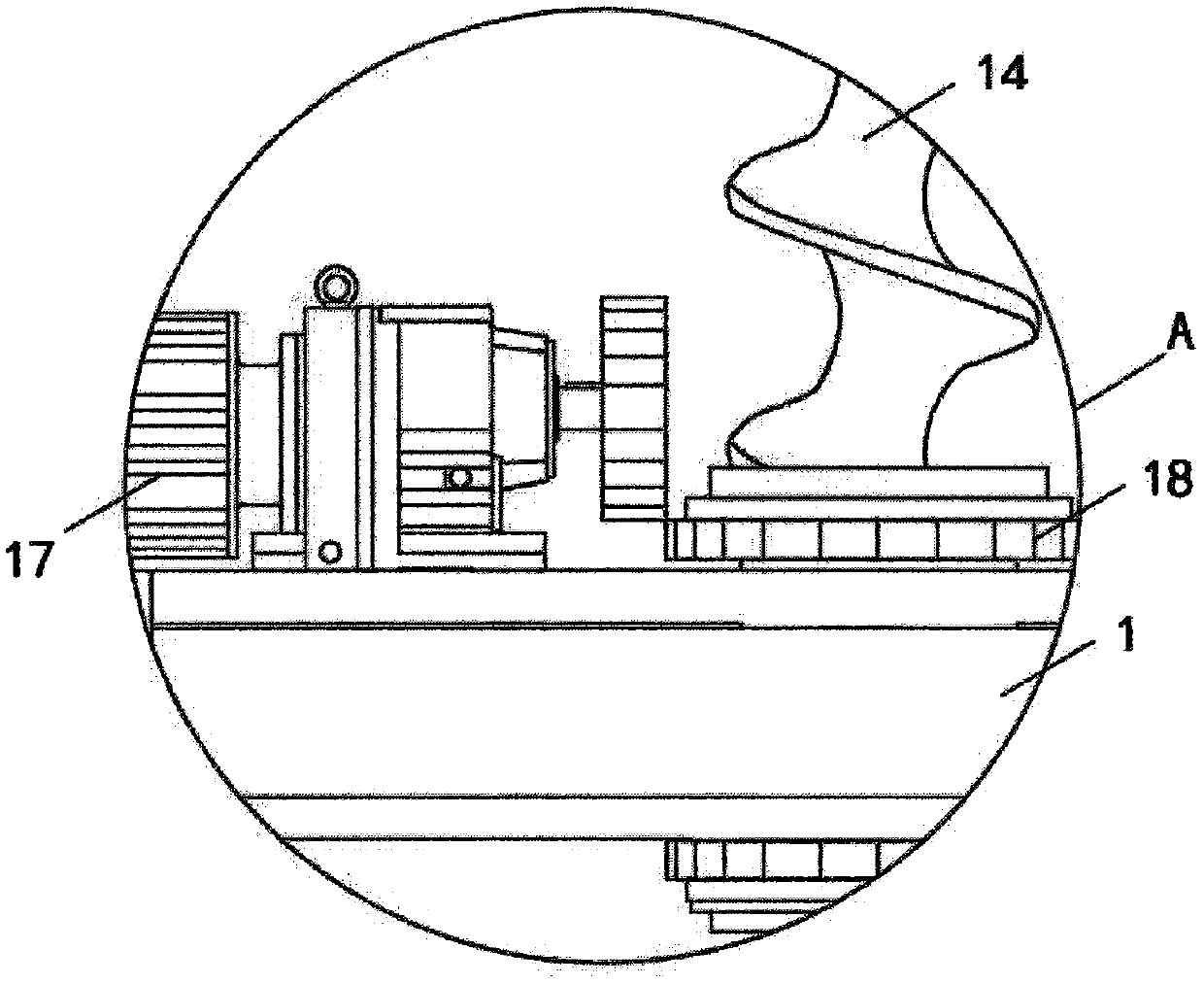

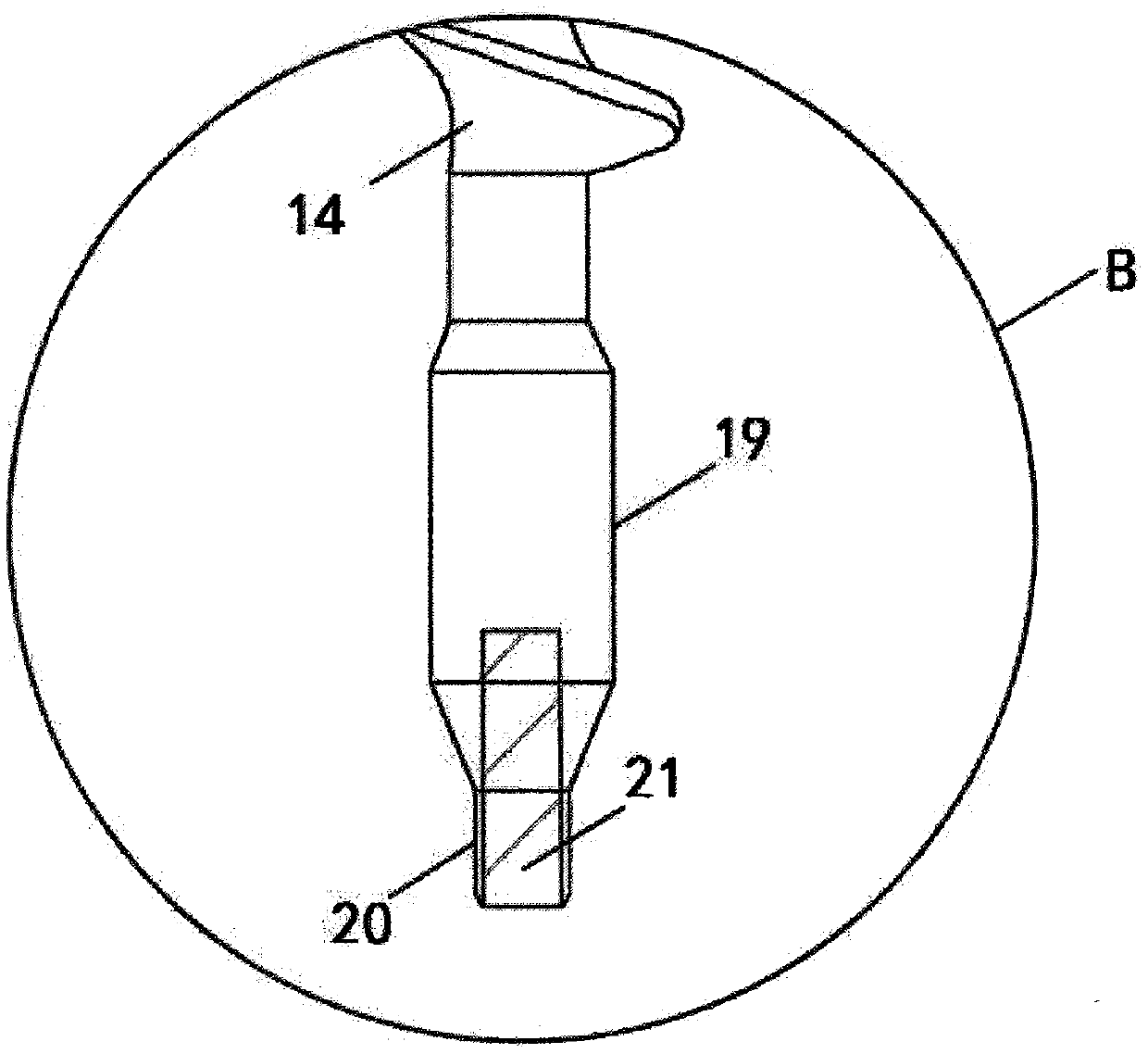

[0020] like Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a high-precision sampler for coal detection, including a bottom frame 1 of the sampler, a buffer moving foot 2, a bottom roller 3, a support base 4, a reinforced limit rod 5, and a fixed middle part. Frame 6, hydraulic cylinder 7, reinforced horizontal shaft rod 8, reinforced vertical shaft rod 9 and a limit sleeve fixed top plate 10, a buffer mobile foot 2 is respectively installed around the bottom of the sampler bottom frame 1, and the bottom of the sampler A middle fixed frame 6 is fixedly installed above the frame 1, and a hydraulic cylinder 7 is respectively installed between the bottom of both sides of the middle fixed frame 6 and the bottom frame 1 of the sampler, and the bottom of each hydraulic cylinder 7 is connected with a reinforced limit rod 5. A support base 4 is installed at the bottom of the hydraulic cylinder 7 inside each of the reinforced limit rods 5, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com