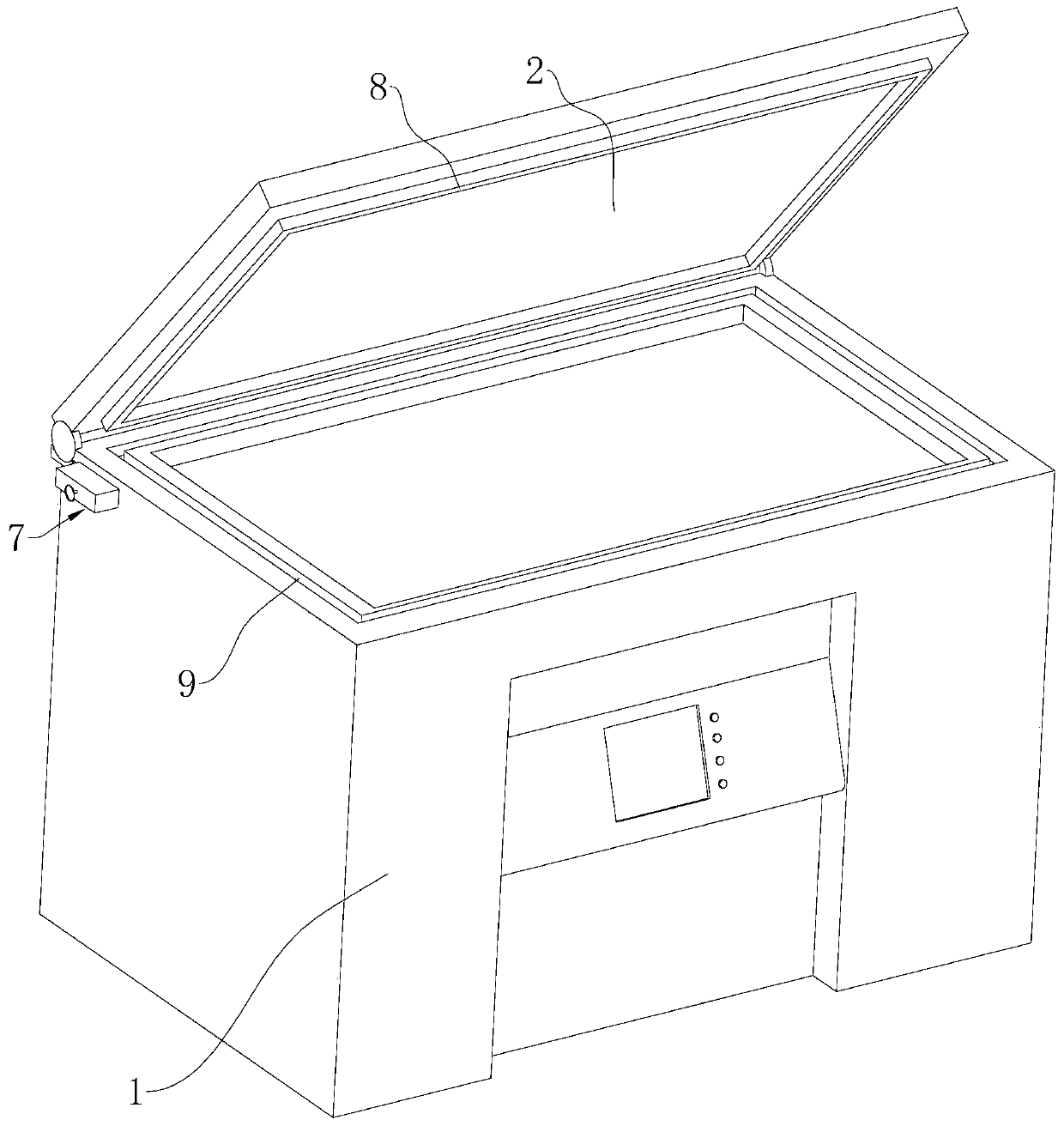

Printing-down machine

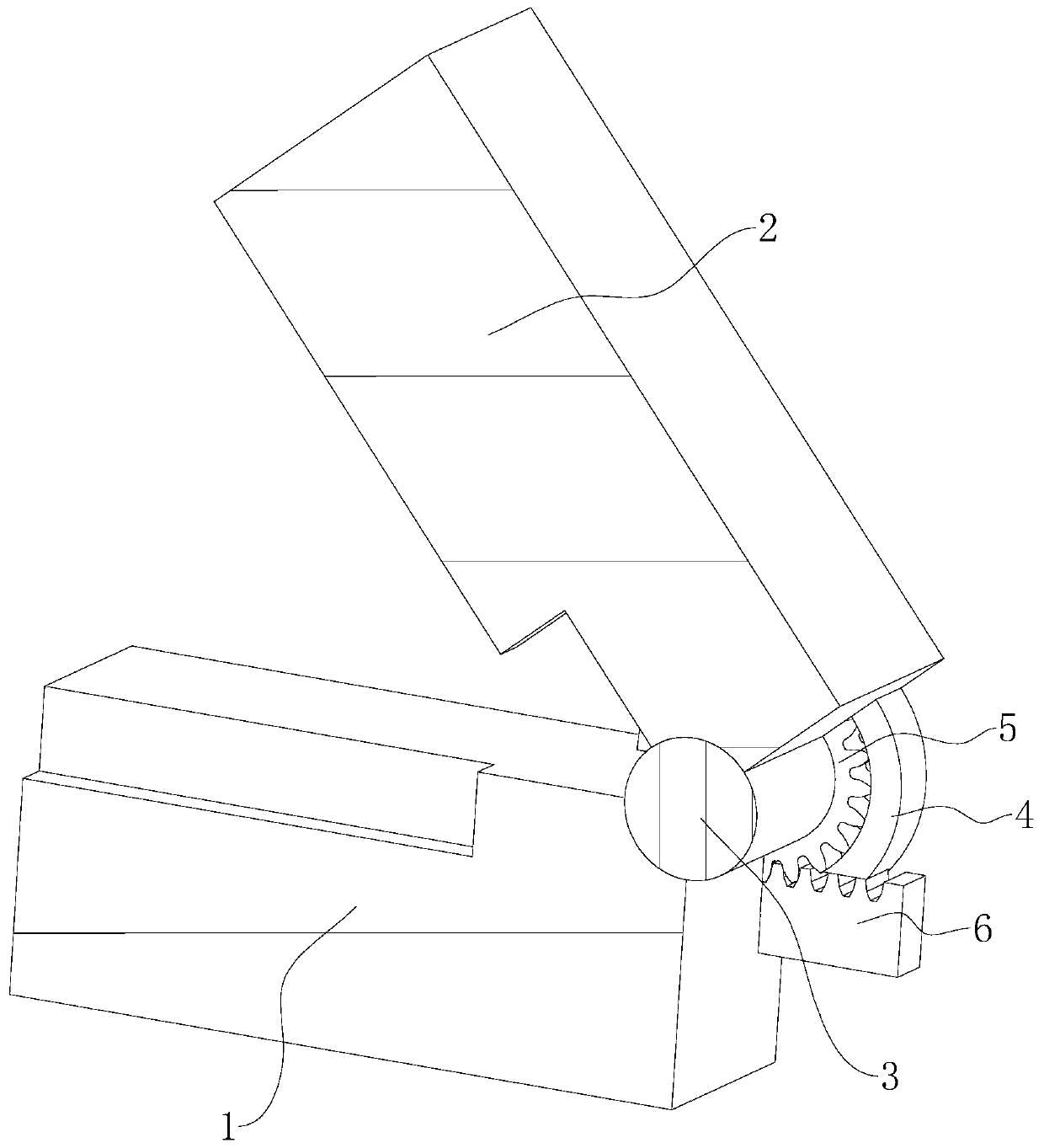

A technology of printing machine and machine body, which is applied in the field of printing machine, which can solve the problems such as turning over the sealing cover and hurting people, damage to the gas spring, loss of the support function of the sealing cover, etc., to achieve the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

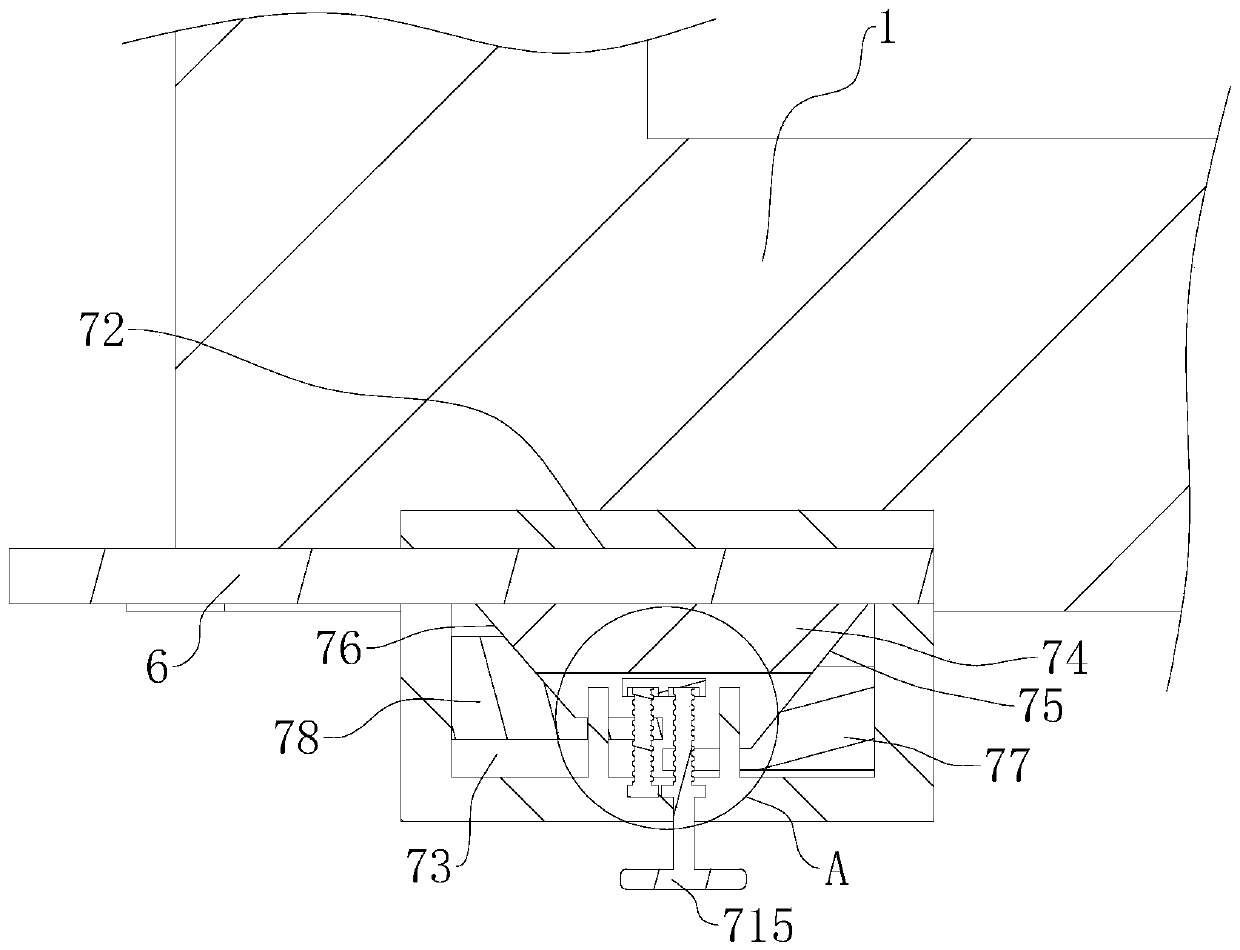

[0038] Embodiment 2: The difference with Embodiment 1 is that, with reference to image 3 , a motor (not shown in the figure) is fixed on the mounting base 71, the output shaft of the motor is fixed coaxially with the end of the screw rod 1 79 outside the mounting base 71, the motor communicates with the external power supply through wires, and is controlled by the control panel opening and closing. In this embodiment, the motor adopts a positive and negative motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com