Method for exchanging adjacent processes of quasi-critical path and equipment

A key path and process technology, applied in the field of automated processing, can solve the problems of poor compactness of serial processes, parallel processing without consideration of parallel processes, poor parallelism, etc., to achieve the effect of expanding solution space, reducing total time, and making up for negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

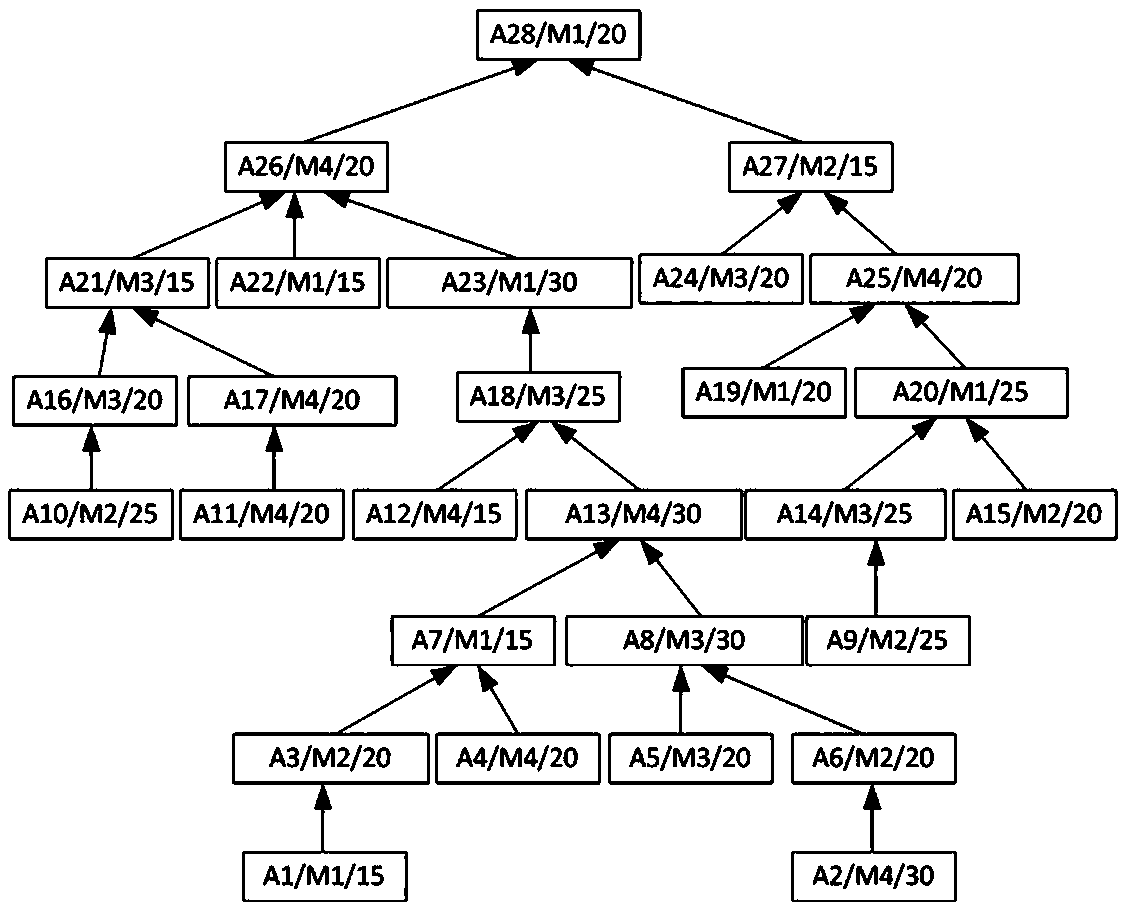

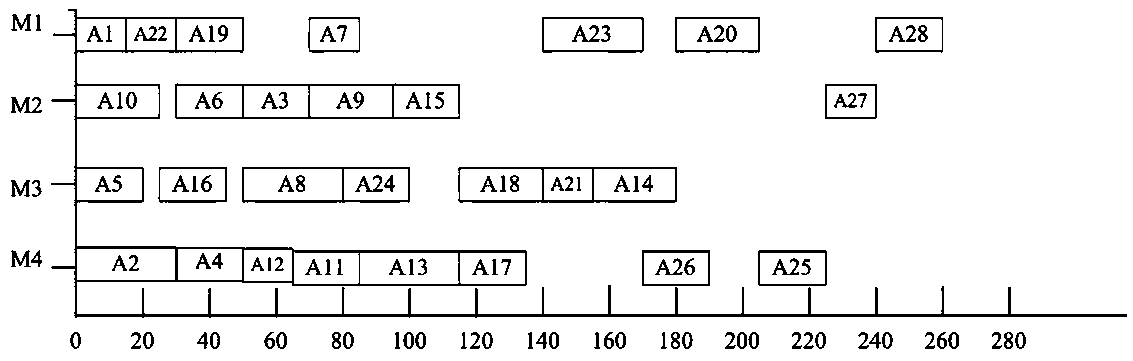

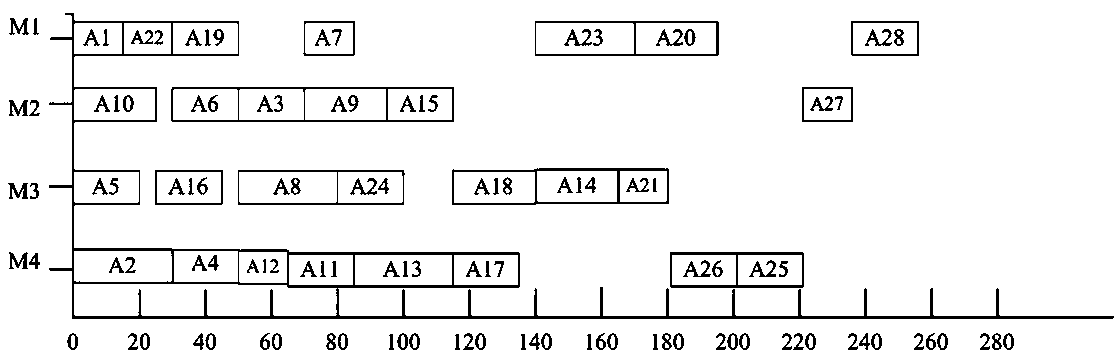

[0036] A method for exchanging a quasi-critical path with adjacent processes of equipment, the scheduling method includes the following steps: using a quasi-critical path strategy to determine the scheduling order of each process in a product processing tree; using a first-time adaptation strategy to determine each process in a product processing tree Based on the original scheduling plan, search for interchangeable adjacent processes on each processing equipment in turn; adjust the scheduling sequence of the swapping process according to the adjacent process swap strategy; and press Adjacent process interchange adjustment strategy, adjust the affected process; get a new product scheduling plan, add it to the product scheduling plan set; find the next interchangeable adjacent process in turn, generate a new product scheduling plan, and Add to the set of product scheduling schemes; after generating all new scheduling schemes, according to the optimal product scheduling scheme se...

Embodiment 2

[0039] refer to Figure 1 to Figure 3 , a method for exchanging a quasi-critical path with an adjacent process of equipment provided by the present invention, comprising the following steps: using a quasi-critical path strategy to determine the scheduling order of each process in the product processing tree; using a first-time adaptation strategy to determine The scheduling time of each process forms the original scheduling plan; based on the original scheduling plan, search for interchangeable adjacent processes on each processing equipment in turn; adjust the scheduling sequence of the swapping process according to the adjacent process swap strategy; And adjust the affected process according to the adjacent process interchange adjustment strategy; get a new product scheduling plan, add it to the product scheduling plan set; find the next interchangeable adjacent process in turn, and generate a new product scheduling plan , and added to the set of product scheduling schemes; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com