Lithium battery liquid cooling box

A technology for lithium batteries and lithium battery packs, which is applied to secondary batteries, battery pack components, circuits, etc., can solve problems such as complex structures, heavy weight of battery packs, bumps and vibrations, and achieve good cooling effects and simple structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

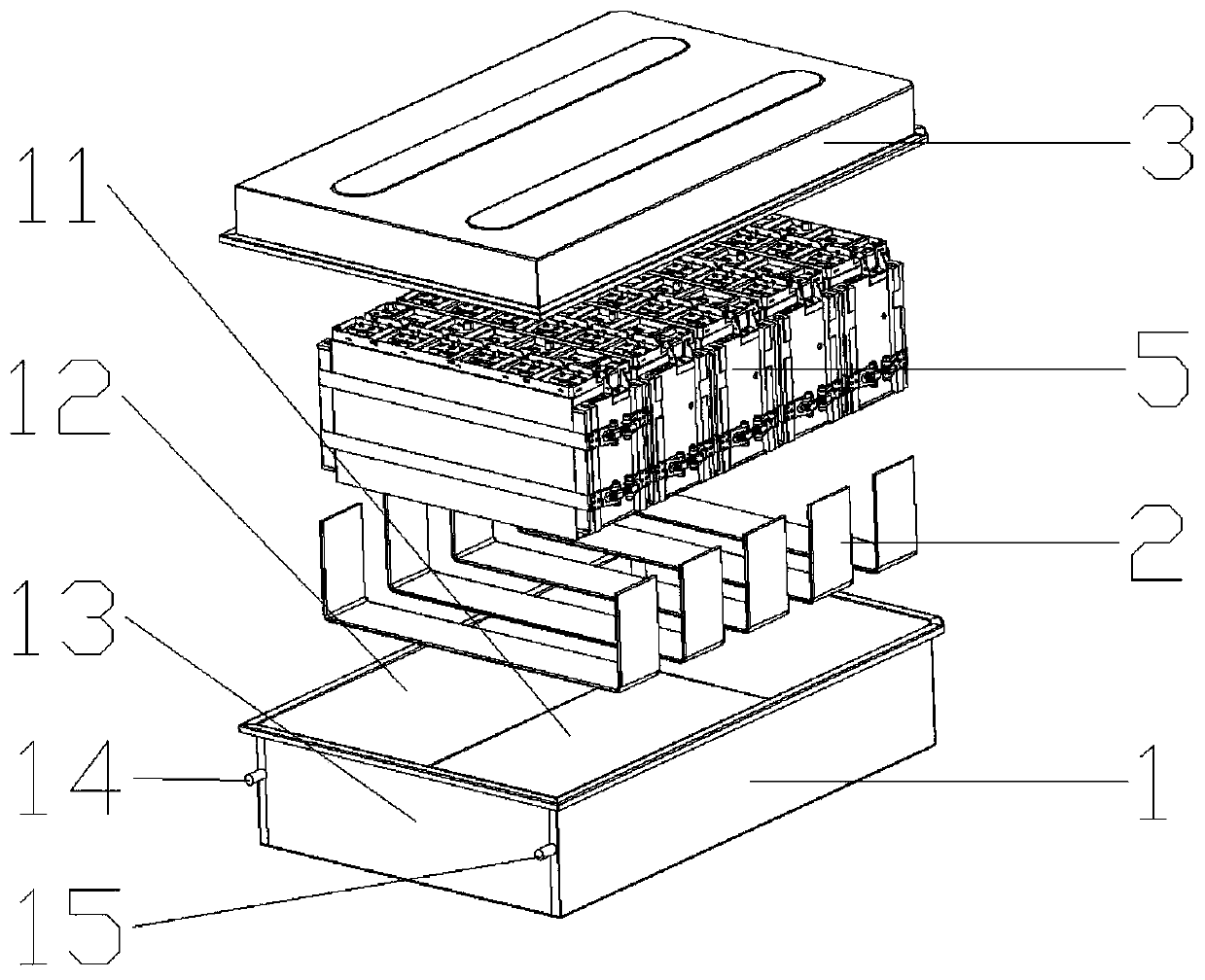

[0023] Such as Figure 1 ~ Figure 2 A liquid cooling box for lithium batteries is shown, which is characterized in that it includes a box body 1, a flat heat pipe 2, and a box cover 3;

[0024] The box body 1 has a square shape and includes a bottom plate 11, two long side plates 12 and two short side plates 13. The bottom plate 11, two long side plates 12 and two short side plates 13 together form a lithium battery The box body 1 is integrally formed, the two long side plates 12 and one short side plate 13 are hollow inside, and the two long side plates 12 are away from the hollow short side plate 13 at one end. The liquid inlet 14 and the liquid outlet 15, the cooling liquid enters the inside of the box 1 through the liquid inlet 14 of the long side plate 12 on one side, and flows through the long side plate and the hollow short side plate on one side. Inside, it flows out through the liquid outlet 15 of the long side plate 12 on the other side.

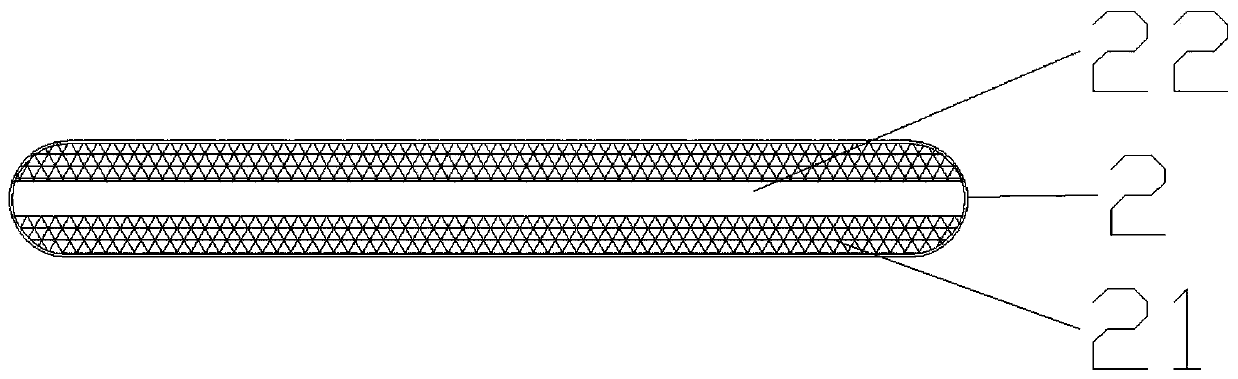

[0025] The flat heat pipe 2 is...

Embodiment 2

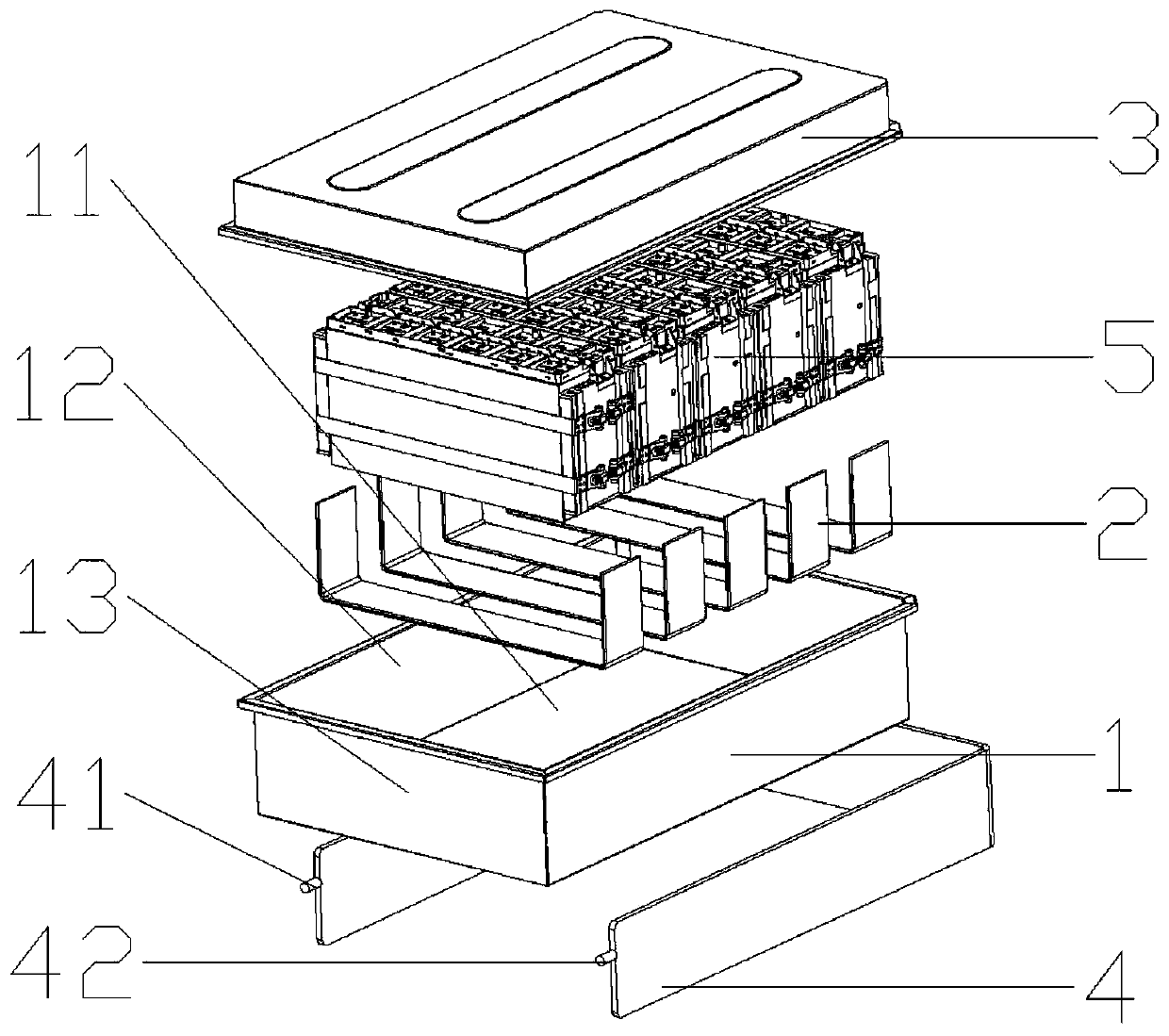

[0041] Such as image 3 The shown liquid cooling box for lithium batteries is characterized in that it comprises a box body 1, a flat heat pipe 2, a box cover 3, and a liquid cooling plate 4.

[0042] The box body 1 has a square shape and includes a bottom plate 11, two long side plates 12 and two short side plates 13. The bottom plate 11, two long side plates 12 and two short side plates 13 together form a lithium battery Set of chambers.

[0043] The flat heat pipe 2 is placed at the bottom of the cavity, the outside is a U-shaped sealed tube, the inside is drawn to a negative pressure, and the inside is provided with a wick 21, a gas channel 22 and a working fluid; the flat heat pipe The bottom of the 2 is placed on the bottom plate 11, and both sides of the flat heat pipe 2 are in contact with the two long side plates 12, which are used to conduct the heat installed on the upper lithium battery pack 5 to the two long sides. 12 side panels.

[0044] The box cover 3 is detachably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com