Liquid injection mechanism and device

A liquid injection and liquid injection port technology, applied in the direction of structural parts, electrical components, circuits, etc., can solve the problems of shell bulging and deformation, slow process, pollution, etc., to achieve convenient exhaust and pressure relief, smooth liquid injection operation, and convenient The effect of exhaust pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

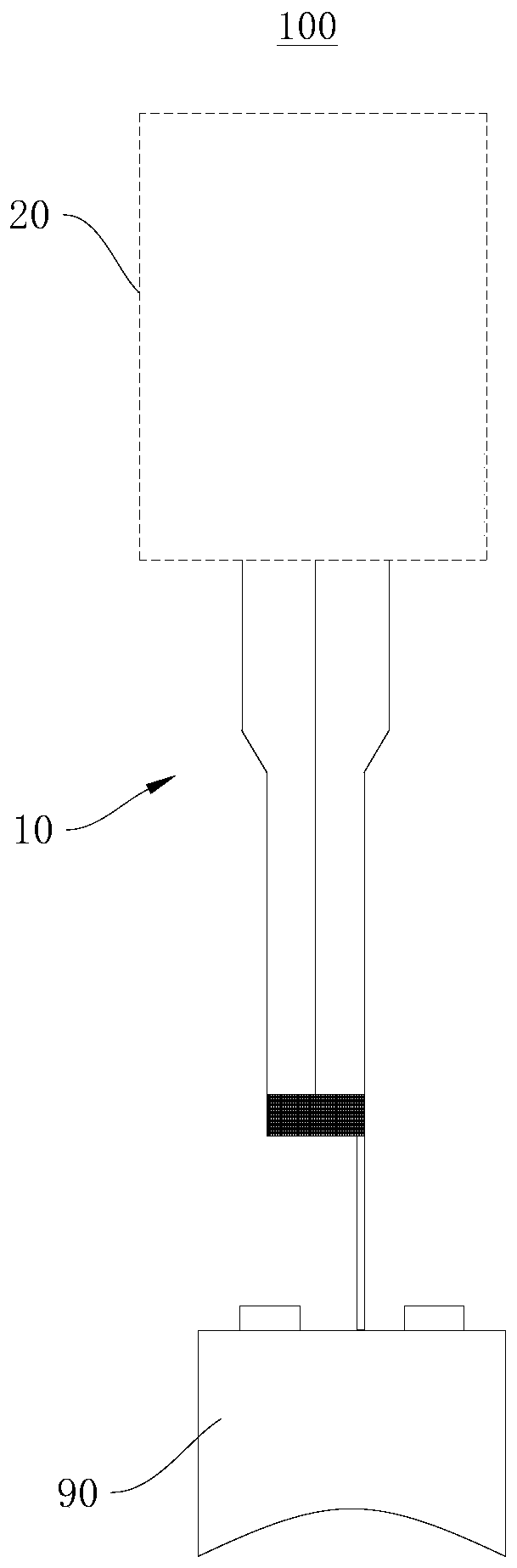

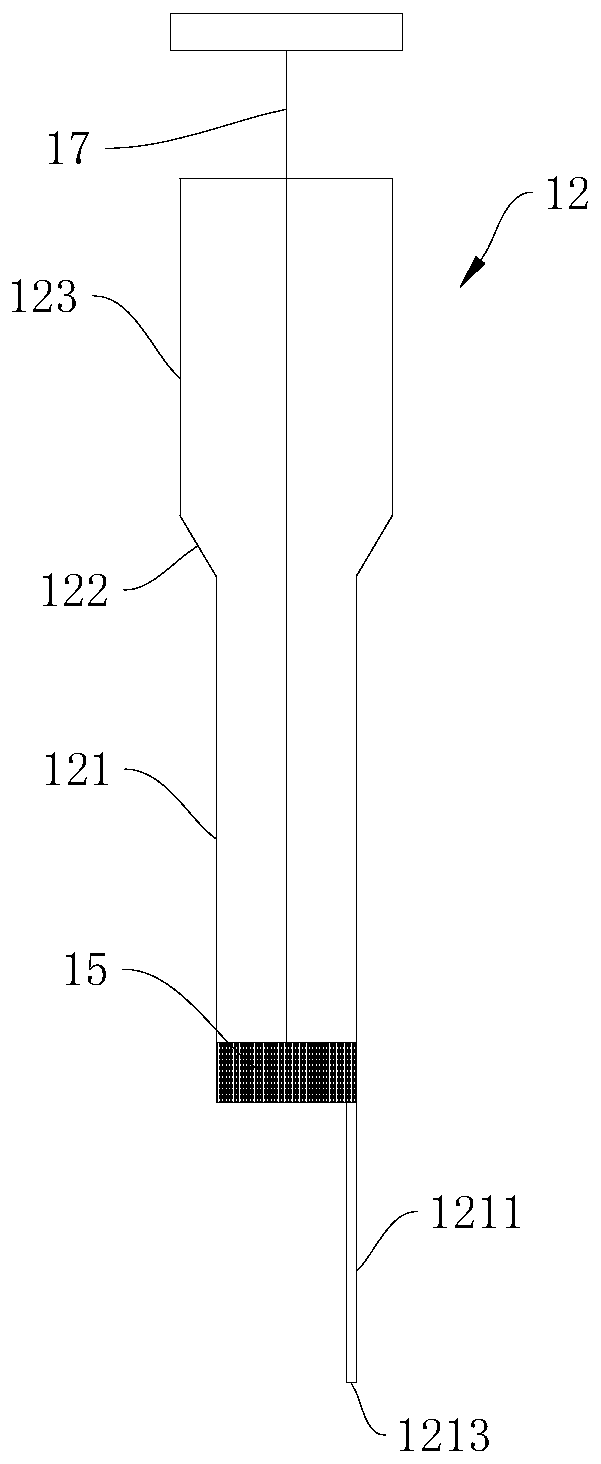

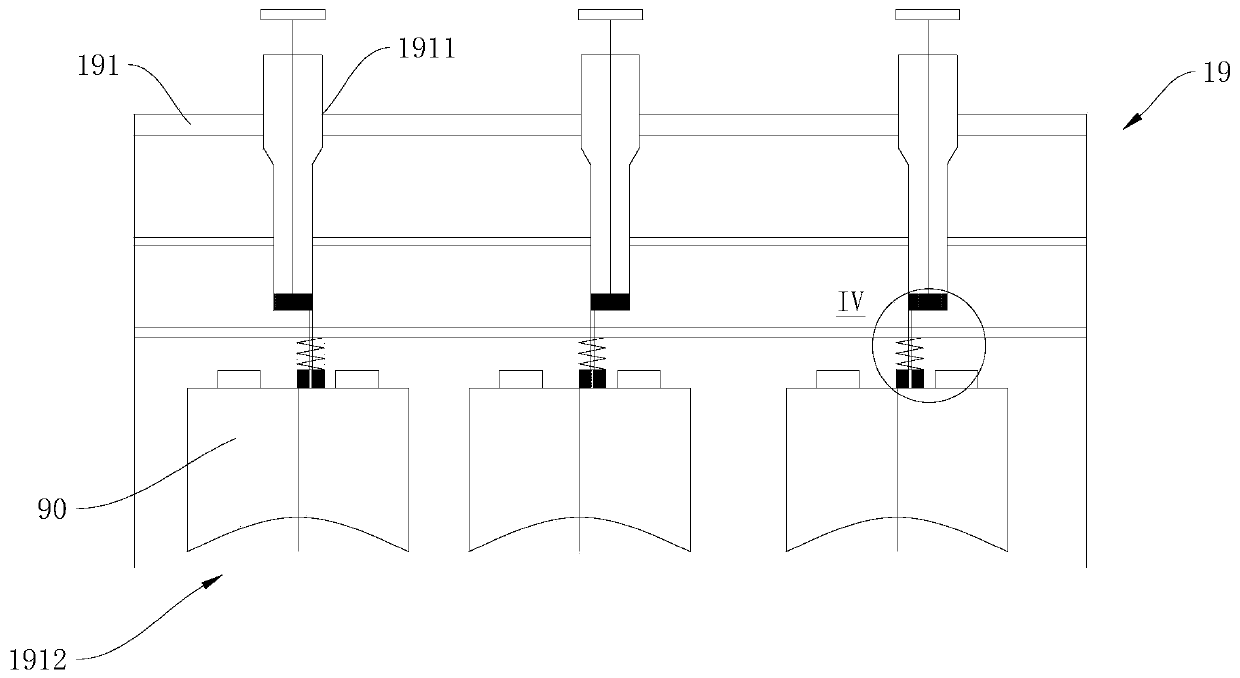

[0032] see figure 1 , figure 1 It is a schematic structural diagram of the liquid injection mechanism 10 applied to the liquid injection device 100 provided by the embodiment of the present invention.

[0033] The embodiment of the present invention provides a liquid injection mechanism 10, which has the characteristics of easy pressure relief, stable liquid injection, and safety and reliability. The liquid injection mechanism 10 can be applied to the liquid injection device 100, the experimental liquid injection mechanism 10, etc. Of course, the liquid injection mechanism 10 can also be used independently.

[0034]Wherein, taking the liquid injection mechanism 10 applied to the liquid injection device 100 as an example, the liquid injection device 100 includes the liquid injection mechanism 10, which injects liquid into the battery cell 90 to be injected through the liquid injection mechanism 10, so as to improve the fluidity of its liquid injection and safety, in addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com