Heating non-combustion smoking set

A heat-not-burn, smoking device technology, applied in tobacco, smoker's products, applications, etc., can solve problems such as affecting the reliability and stability of circuit connections, the number of puff ports on battery life, and the inability to achieve automatic assembly. Easy mass production, lower production cost, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

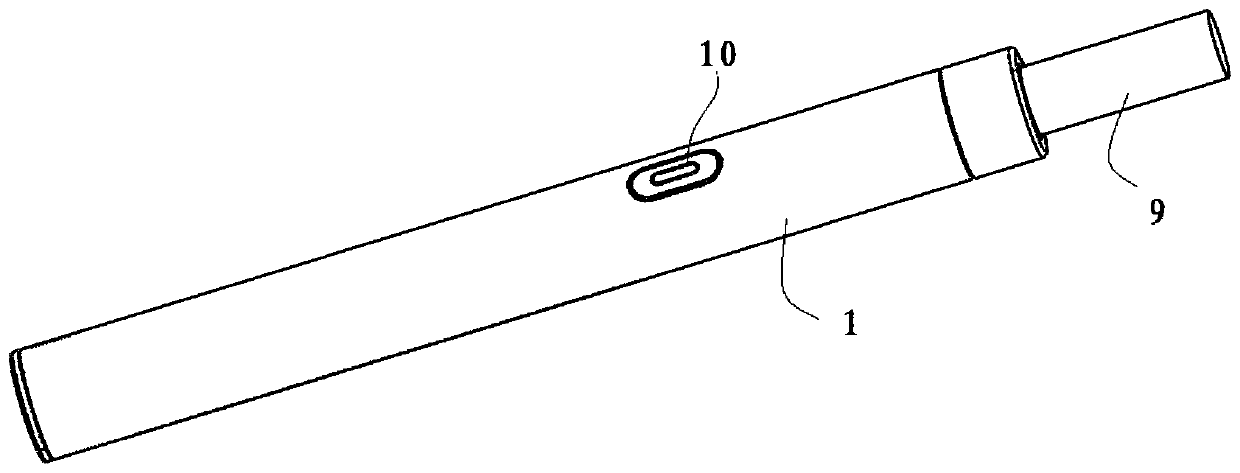

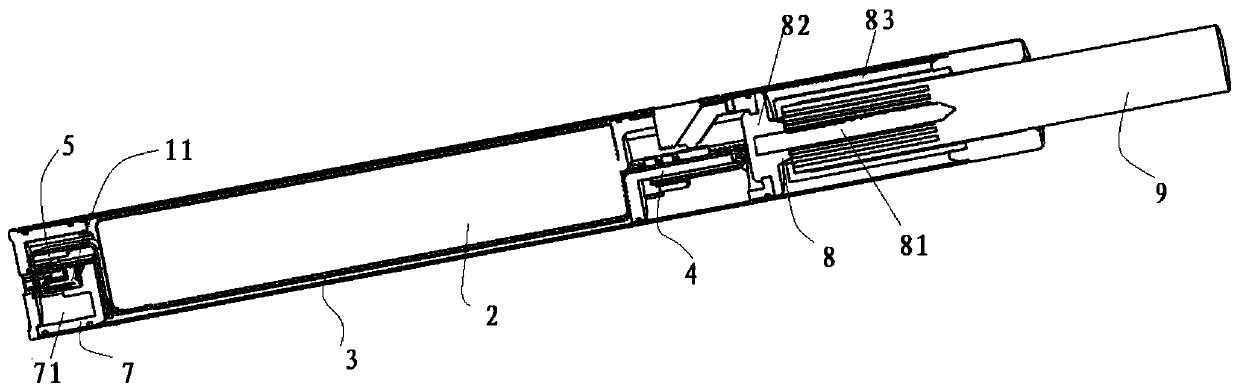

[0051] like Figure 1 to Figure 7 As shown, a heat-not-burn smoking appliance is used for heating low-temperature burn-not-burn cigarettes.

[0052] The smoking appliance includes a shell 1 with a hollow cavity, for example, figure 1 Shown is a shell 1 with a cylindrical shape and a smooth surface, but in the present application, the shape of the shell 1 is not limited to the cylindrical structure shown in the figure, and may also be oval in cross section rod-shaped structure, a rod-shaped structure with a square cross-section, etc., the surface of the shell 1 is not necessarily a smooth surface, it can also be a frosted surface that can increase the texture, and have edges that can increase friction to prevent the smoking device from falling off from the user's hand. The surface of the edge, the surface with various patterns or textures added to improve the aesthetic performance of the appearance of the smoking set, etc.

[0053] A battery 2 is arranged in the hollow cavity...

Embodiment 2

[0091] The structure and principle of this embodiment and embodiment 1 are basically the same, the difference is:

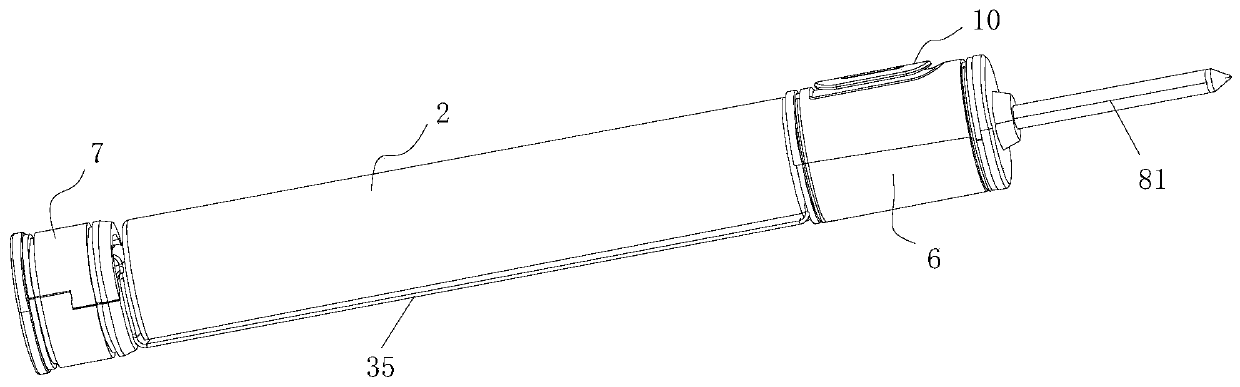

[0092] In Embodiment 1, the circuit board supporting member 6 adopts a first clamping part 61 and a second clamping part 62 to form a substantially cylindrical structure to form the first chamber 63, the first clamping The piece 61 and the second clamping piece 62 are equivalent to clamping the first circuit region 33 along the thickness direction of the first circuit region 33 .

[0093] In this embodiment, the first clamping piece is adjacent to the battery 2, the second clamping piece is adjacent to the heat insulating sleeve 83, and the first clamping piece and the second clamping piece Equivalent to clamping the first circuit region 33 along the length direction of the first folded portion 331 of the first circuit region 33, the circuit board support member 6 does not have the first cavity as described in Embodiment 1 .

[0094] In this embodiment, the swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com