Sludge suction dredger

A technology of suction mud machine and suction pipe, which is applied to the feeding/discharging device, chemical instrument and method, separation method, etc. Achieve the effect of preventing clogging, simple structure and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

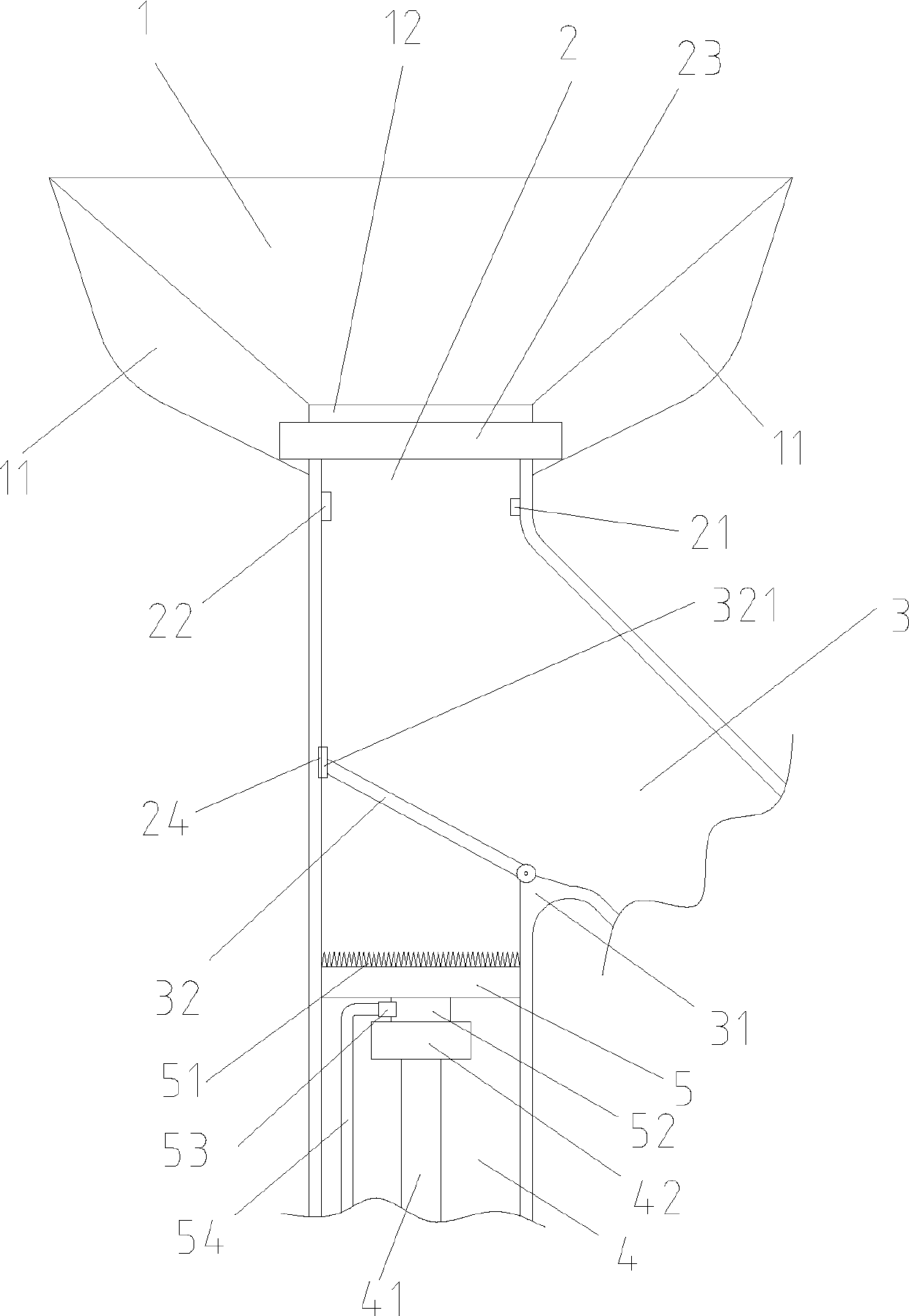

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: figure 1 Shown, a kind of dredger, comprises working bridge, dredging pipe 2, mud discharge pipe, submerged dredging pump, driving mechanism and electric control box, and described dredging pipe 2 outer jacket is provided with mud-lifting baffle 1, Both sides of the mud raising baffle 1 are provided with guide plates 11, and the guide plates 11 guide the sludge on the mud raising baffle 1 to the nozzle 12 of the mud suction pipe 2, and the mud suction pipe 2 A sludge pipe 3 and a cleaning chamber 4 are connected; the end of the mud suction pipe 2 is provided with a screening part 23, and a screen is provided in the screening part 23, and a piston head 5 is provided in the cleaning chamber 4, The end surface of the piston head 5 is provided with several thorns 51, the piston head 5 is provided with an air intake portion 52, the air intake port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com