Stamping dies for protective valve brackets with ejectors based on the principle of smooth lifting

A technology for stamping dies and protecting valves, applied in the field of stamping dies for protecting valve brackets, can solve problems such as impact on the bottom of the workpiece, ejection of the workpiece from the mold, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

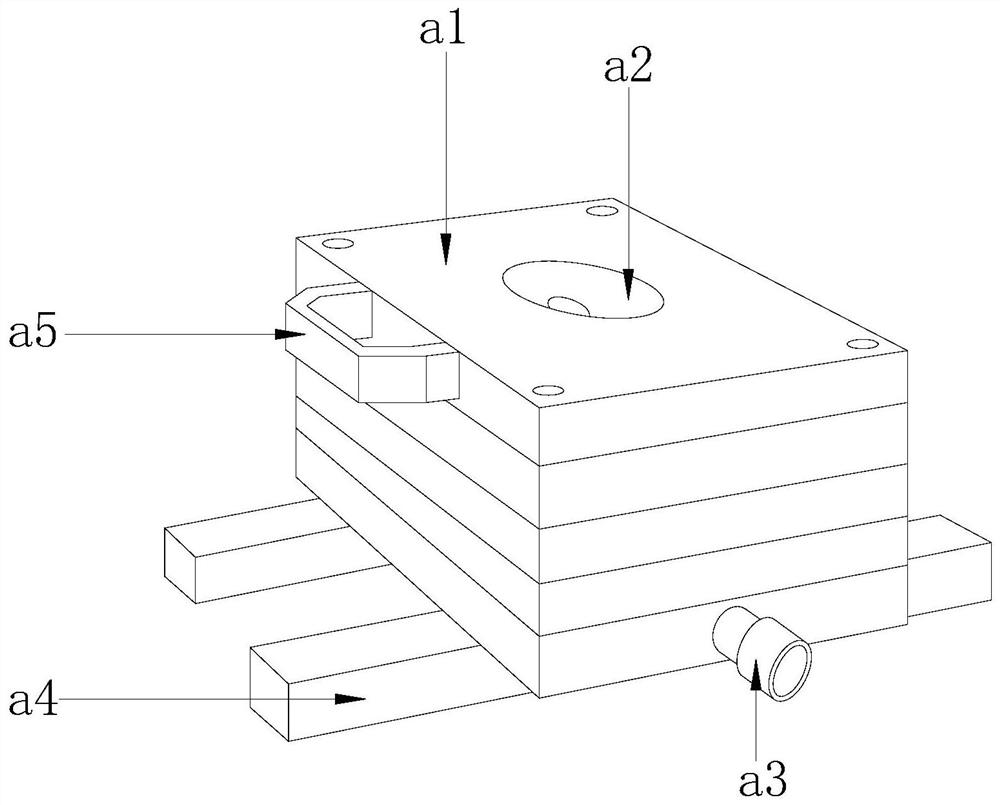

[0029] see Figure 1-Figure 6 , the present invention provides a stamping die for a protective valve bracket with ejector material based on the principle of smooth lifting. The handle a5 is installed on the upper left side of the mold main body a1 by embedding. The top of the mold main body a1 is provided with a finale assembly port a2, which is an integrated structure. The air pipe joint a3 is provided through the front bottom of the mold main body a1. There are two bottom bars a4, which are installed on the bottom of the mold main body a1 by welding. The final shaft assembly port a2 is used to assemble and fix the mold main body a1 and the stamping equipment. a1 is disassembled, the bottom cross bar a4 is used to assemble and fix the bottom of the mold main body a1, and the air pressure enters the interior of the mold main body a1 from the air pipe joint a3 for pneumatic control.

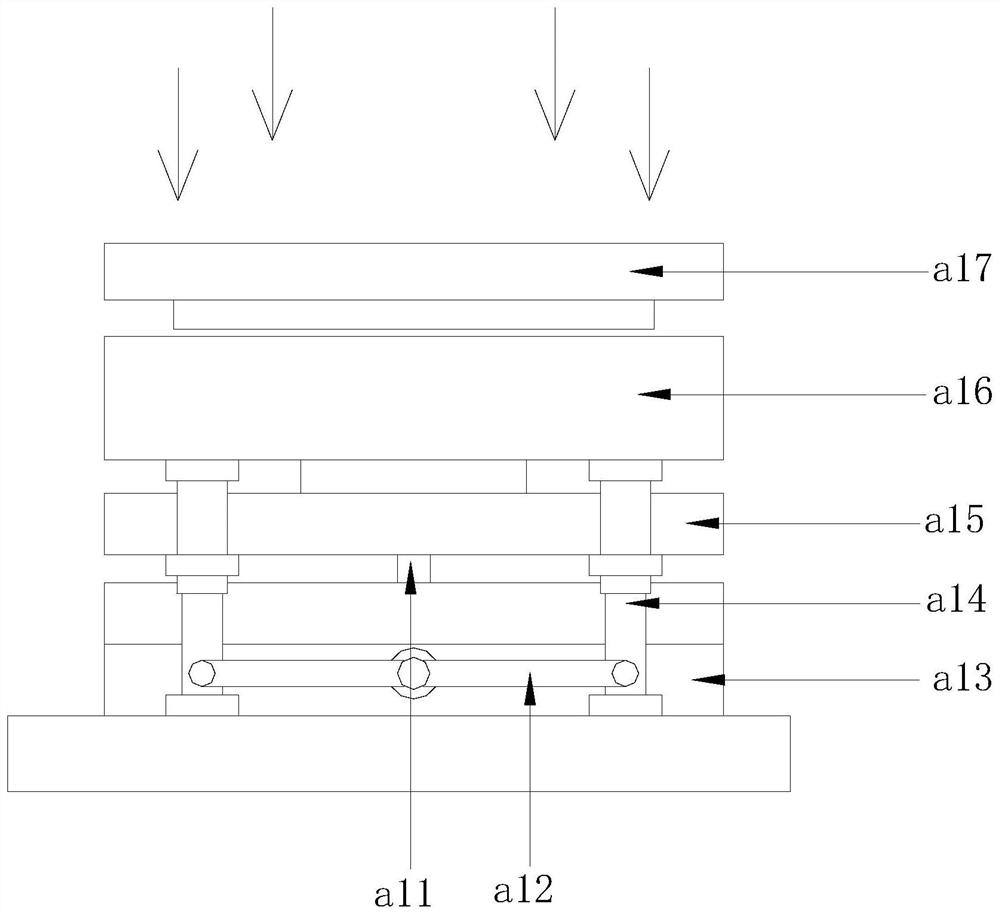

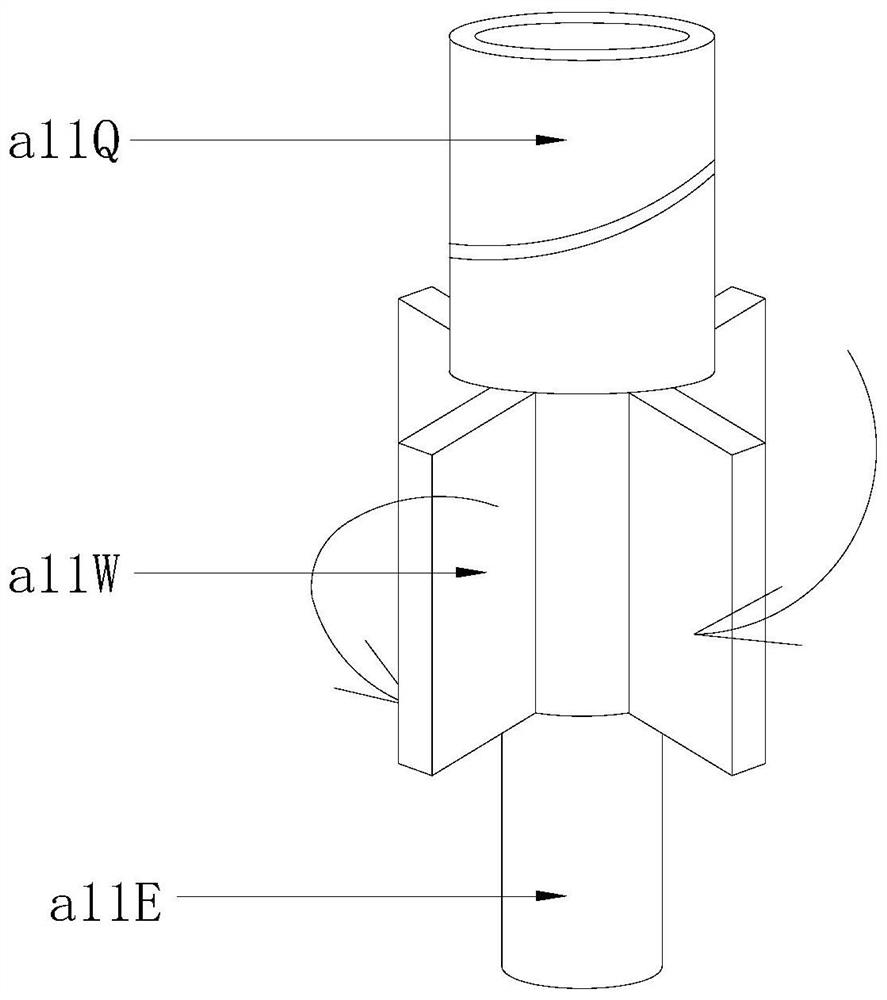

[0030] The mold body a1 includes a driving shaft a11, a distribution pipe a12, a bottom mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com